Dust remover for travelling material spreading

A dust removal device and fabric distribution technology, which is applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of fine particles and powder materials not being collected well, working environment pollution, and large material dust, so as to prevent disadvantages Impact, prevent material dust, overcome the effect of erosion and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

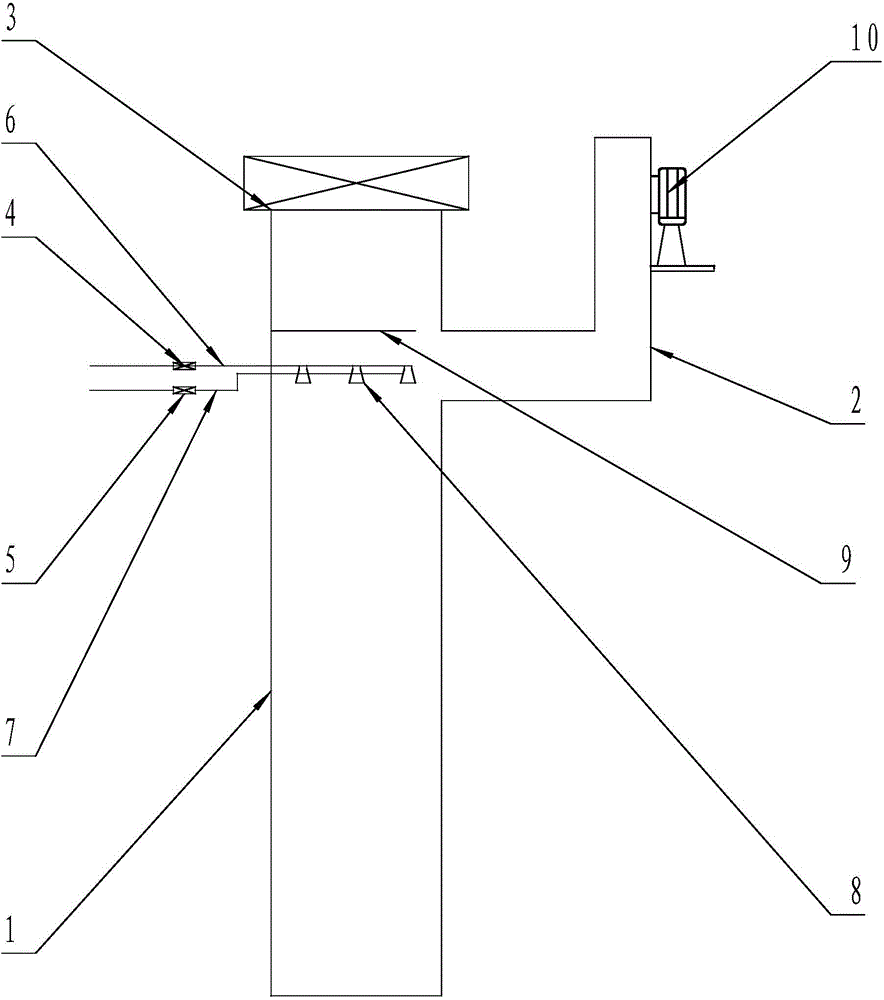

[0016] Such as figure 1 As shown, a driving cloth dust removal device includes a cloth pipe 1 and a dust collection pipe 2. A discharge valve 3 is installed on the mouth of the cloth pipe 1, and a Roots blower 10 is installed on the mouth of the dust collection pipe 2. , it is characterized in that: a cloth dust removal device is also installed on the side wall of the cloth distribution pipe 1, and the cloth dust removal device includes a water supply pipeline 6, a compressed air pipeline 7, an atomizing nozzle 8, the water supply pipeline 6 and the compressed air pipeline 7 Pass through the side wall of one side of the distribution pipe 1 and be fixedly installed on the side wall of the distribution pipe 1. The water supply pipe 6 and the compressed air pipe 7 are equidistantly installed with at least 3 atomizing nozzles on the part inside the distribution pipe 1 8. The water supply and compressed air can enter each atomizing nozzle 8 through the water supply pipeline 6 and t...

Embodiment 2

[0019] Such as figure 1 As shown, a driving cloth dust removal device includes a cloth pipe 1 and a dust collection pipe 2. A discharge valve 3 is installed on the mouth of the cloth pipe 1, and a Roots blower 10 is installed on the mouth of the dust collection pipe 2. , it is characterized in that: a cloth dust removal device is also installed on the side wall of the cloth distribution pipe 1, and the cloth dust removal device includes a water supply pipeline 6, a compressed air pipeline 7, an atomizing nozzle 8, the water supply pipeline 6 and the compressed air pipeline 7 Pass through the side wall of one side of the distribution pipe 1 and be fixedly installed on the side wall of the distribution pipe 1. The water supply pipe 6 and the compressed air pipe 7 are equidistantly installed with at least 3 atomizing nozzles on the part inside the distribution pipe 1 8. The water supply and compressed air can enter each atomizing nozzle 8 through the water supply pipeline 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com