Counterweight moving apparatus and crane

A mobile device and crane technology, applied in cranes and other directions, can solve the problems of low flexibility of counterweights and easy to limit the performance of construction machinery, and achieve the effects of increasing stable torque, reducing stable torque and enhancing flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

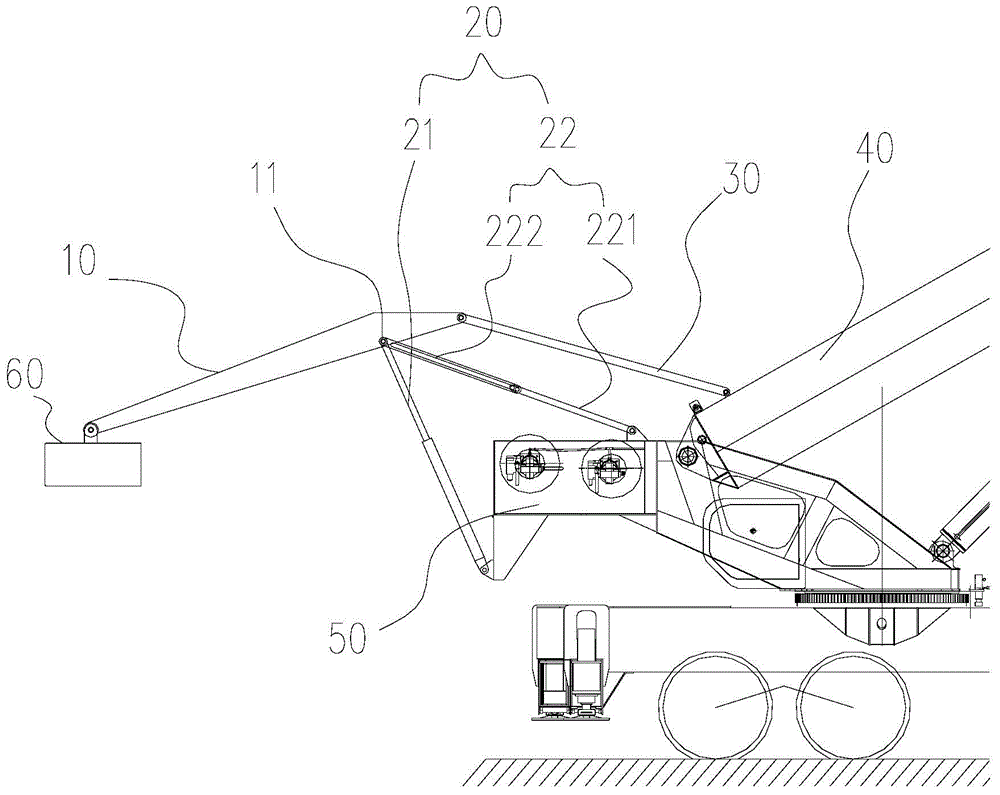

[0044] The main difference between the counterweight moving device of Embodiment 2 and Embodiment 1 is that the support rod 22 includes a first pull plate 221 and a second pull plate 222 that are movably connected, the second pull plate 222 has a slide groove 2221, and the first pull plate 221 has pin shaft 2211 that is slidably arranged in the chute 2221, and the free end of the second pull plate 222 forms the second installation end, and the free end of the first pull plate 221 is hinged with the middle part of swinging part 10 (not shown in the figure) out). The above structure realizes the expansion and contraction of the support rod 22 . The setting positions of the first pull plate 221 and the second pull plate 222 in this embodiment are opposite to those in the first embodiment, and their working process is similar to that in the first embodiment, and will not be repeated here.

Embodiment 3

[0045] The main difference between the counterweight moving device of Embodiment 3 and Embodiment 1 is that the support part 20 includes a second lifting cylinder and a third lifting cylinder, the first end of the second lifting cylinder is the third installation end, and the third lifting cylinder The first end of the lifting cylinder is the fourth installation end, the second end of the second lifting cylinder and the second end of the third lifting cylinder are both hinged with the middle of the swing part 10, or the second end of the second lifting cylinder It is hinged with the middle part of the swing part 10, and the second end of the third lifting cylinder is hinged with the middle part of the second lifting cylinder (not shown in the figure). In this embodiment, the above-mentioned first mounting end (ie, the first end of the second lifting cylinder) and the second mounting end (ie, the first end of the third lifting cylinder) are both hinged on the fixed structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com