A method for preparing microgel by enzymatic polymerization

A microgel and enzymatic technology, applied in the field of enzymatic polymerization to prepare microgel, can solve the problems of little research on microgel, and achieve the effects of mild conditions, high catalytic efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] At room temperature (25°C), accurately weigh 1.2g of Tween 20 and 2.4g of Span 80 into a 100mL three-neck flask, add 16.4g of n-octane, 130μL of acetylacetone and a stirrer, and control a certain stirring rate to mix Evenly, the oil phase is formed, and the argon gas is started to remove the oxygen in the device.

[0038] Add 310 μL of monomeric DMAA, 7.2 mg of cross-linking agent MBA, and 3.37 mL of deionized water into a small sample tube, ultrasonicate for a period of time, then add 9 mg of horseradish peroxidase HRP, mix well, and draw the above mixture with a syringe Inject into the oil phase dropwise, and stir for 30 minutes with magnetic force.

[0039] Then, slowly add 320 μL of hydrogen peroxide solution (0.2 M) into the oil-water mixture with a micro-syringe, and continue to stir and ventilate.

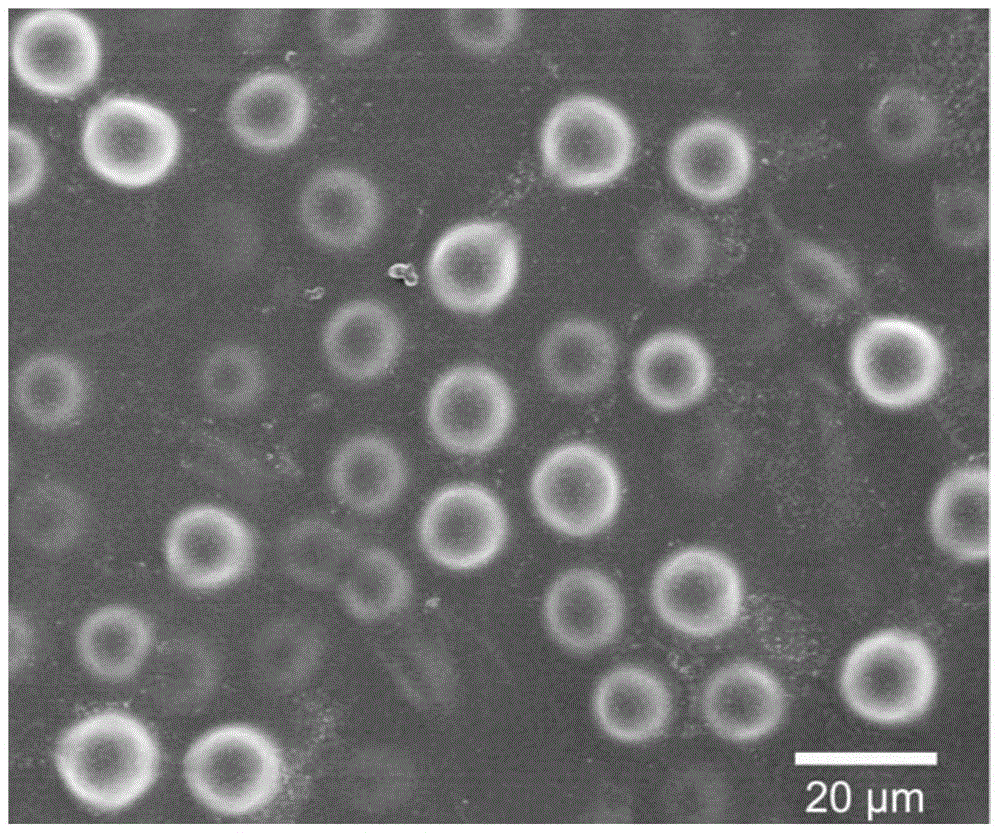

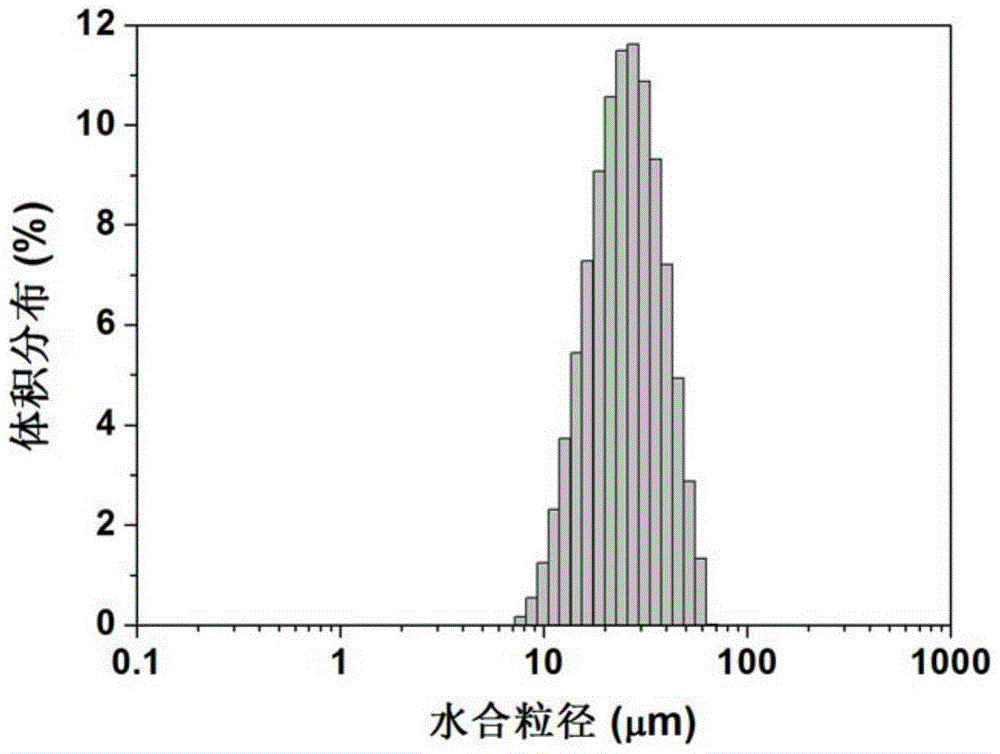

[0040] After reacting for 6 hours, add excess ethanol to break the emulsion, centrifuge, take the precipitate and wash it twice with ethanol and once with water to r...

Embodiment 2

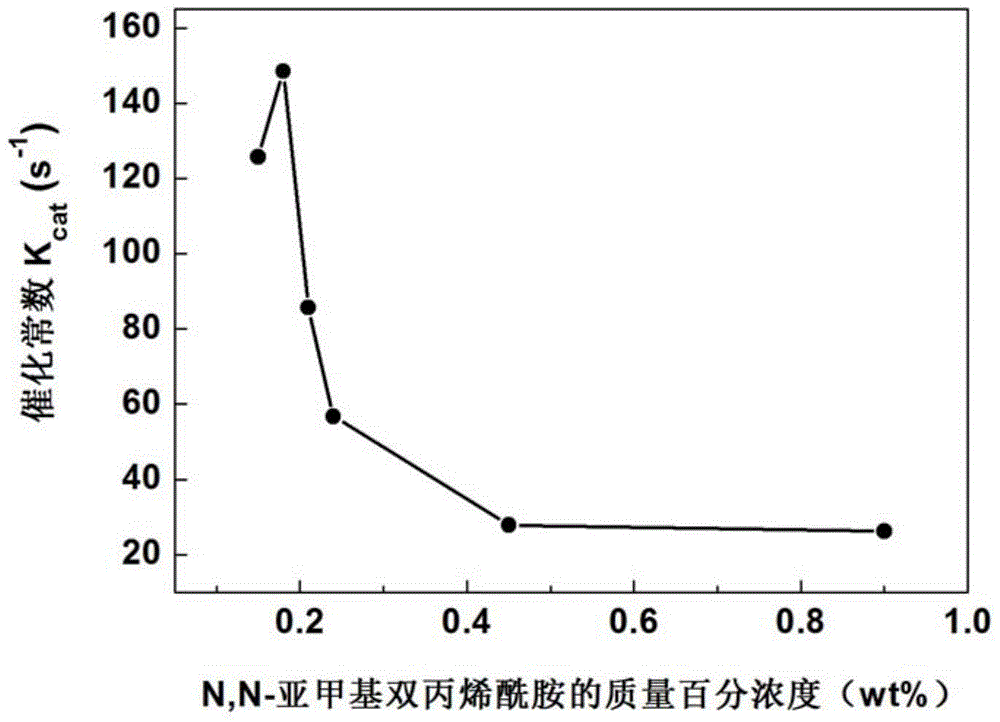

[0043] The kinetics of enzyme catalysis was studied by using horseradish peroxidase HRP to catalyze hydrogen peroxide and o-phenylenediamine (OPD) to generate 2,3-diaminophenazine as a model reaction.

[0044] Firstly, a 50 mM phosphate buffer solution (hereinafter referred to as PBS buffer solution, ie the water phase) with a pH of 7.0 was prepared with disodium hydrogen phosphate and potassium dihydrogen phosphate.

[0045] Then, accurately weigh a certain amount of microgel jelly at room temperature, dissolve it in a certain amount of PBS buffer solution, and shake to form a uniform and dilute suspension. Take a certain amount of suspension in a quartz cuvette, then add PBS buffer and OPD solution to form a 1.99mL mixed solution.

[0046] Finally, inject 10 microliters of 30% hydrogen peroxide with a micro-syringe, stir with a needle for about 7 seconds, and use the dynamic mode of the UV-Vis spectrophotometer to measure the absorbance at 450nm (maximum absorption wavelength)...

Embodiment 3

[0050] This example prepares poly N,N-dimethylacrylamide (PDMAA) microgels, specifically including the following steps:

[0051] (1) After mixing n-octane and acetylacetone evenly, add an emulsifier, mix well to make an oil phase, and inject argon to remove oxygen;

[0052] (2) Take a certain amount of N,N-dimethylacrylamide, add N,N-methylenebisacrylamide and deionized water in sequence, and mix ultrasonically until the N,N-methylenebisacrylamide is completely dissolved Afterwards, add horseradish peroxidase again, stir well, make aqueous phase solution;

[0053] (3) adding the aqueous phase solution prepared in step (2) dropwise into the oil phase of step (1), stirring evenly to obtain an inverse emulsion;

[0054] (4) In the inverse emulsion prepared in step (3), add hydrogen peroxide dropwise while stirring, continue to stir, and continue to feed argon to carry out polymerization;

[0055] (5) After the polymerization reaction in step (4) is finished, add excess ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com