Preparation technology of waterproof climbing rope

A preparation process and technology for mountaineering ropes, which are applied in rope-making auxiliary devices, textiles and papermaking, textile cables, etc., can solve the problems that nylon mountaineering ropes will sink into the bottom of the water, the weight of nylon mountaineering ropes will increase, and users will be inconvenient. Achieve huge market prospects and economic benefits, increase practicability, and reduce water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

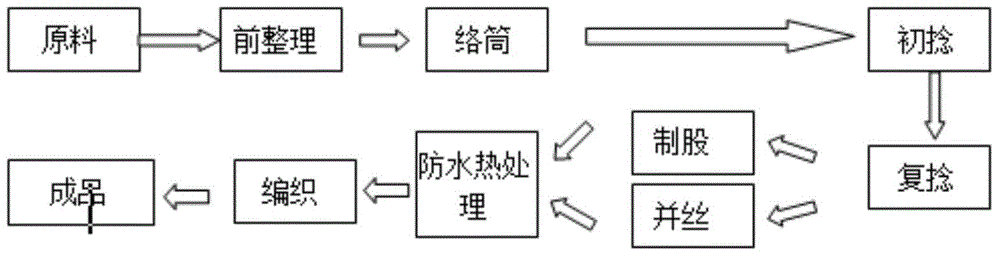

[0018] The detailed preparation process of this embodiment is as follows:

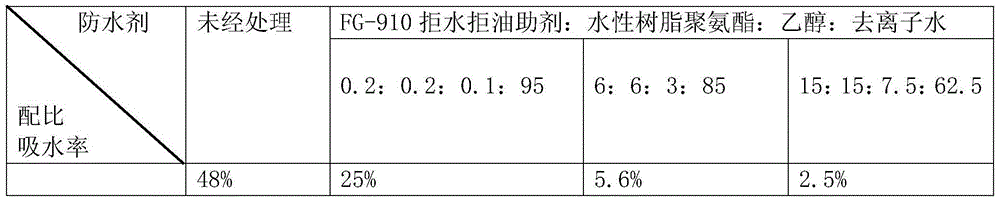

[0019] (1) The raw materials are processed by pre-arrangement, winding, initial twisting, re-twisting, stranding and doubling to obtain a number of rope cores with uniform twist and rope sheaths evenly and tightly woven on the rope core. The rope core includes several rope cores with uniform twist Small strands are arranged in parallel in the rope sheath, and the rope core is divided into s twist direction and z twist direction, and the number of the two is equal; (2) Water and oil repellent additives, water-based resin polyurethane, ethanol, and deionized water are configured according to the proportion Prepare FG-910 water and oil repellent finishing agent, immerse the rope core in the prepared finishing agent, take it out after 2 minutes, the prepared ratio is FG-910 water and oil repellent auxiliary agent 0.2, water-based resin polyurethane 0.2, ethanol 0.1, deionized Water 95.

[0020] (3) Place ...

Embodiment 2

[0022] The detailed preparation process of this embodiment is as follows:

[0023] (1) The raw materials are processed by pre-arrangement, winding, initial twisting, re-twisting, stranding and doubling to obtain a number of rope cores with uniform twist and rope sheaths evenly and tightly woven on the rope core. The rope core includes several rope cores with uniform twist Small strands are arranged in parallel in the rope sheath, and the rope core is divided into s-twist and z-twist, the number of which is equal; (2) FG-910 water and oil repellent additive, water-based resin polyurethane, ethanol, deionized water Configure FG-910 water and oil repellent finishing agent according to the ratio, immerse the rope core in the prepared finishing agent, take it out after 2 minutes, and the prepared ratio is FG-910 water and oil repellent auxiliary agent 6, water-based resin polyurethane 6, ethanol 3 , Deionized water 85.

[0024] (3) Place the obtained product of step (2) in a high-...

Embodiment 3

[0026] The detailed preparation process of this embodiment is as follows:

[0027] (1) The raw materials are processed by pre-arrangement, winding, initial twisting, re-twisting, stranding and doubling to obtain a number of rope cores with uniform twist and rope sheaths evenly and tightly woven on the rope core. The rope core includes several rope cores with uniform twist Small strands are arranged in parallel in the rope sheath, and the rope core is divided into s-twist and z-twist, the number of which is equal; (2) FG-910 water and oil repellent additive, water-based resin polyurethane, ethanol, deionized water Configure FG-910 water and oil repellent according to the ratio

[0028] Finishing agent, immerse the rope core in the prepared finishing agent, take it out after 2 minutes, and the prepared ratio is FG-910 water and oil repellent additive 15, water-based resin polyurethane 15, ethanol 7.5, deionized water 62.5.

[0029] (3) Place the obtained product of step (2) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap