Water diversion pipe structure in local material dam and construction method

A construction method and technology for water diversion pipes, which are applied to the structure of water diversion pipes in local material dams and construction fields, can solve problems such as reducing the engineering volume of water diversion systems, and achieve the effects of shortening construction period, ensuring safety and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

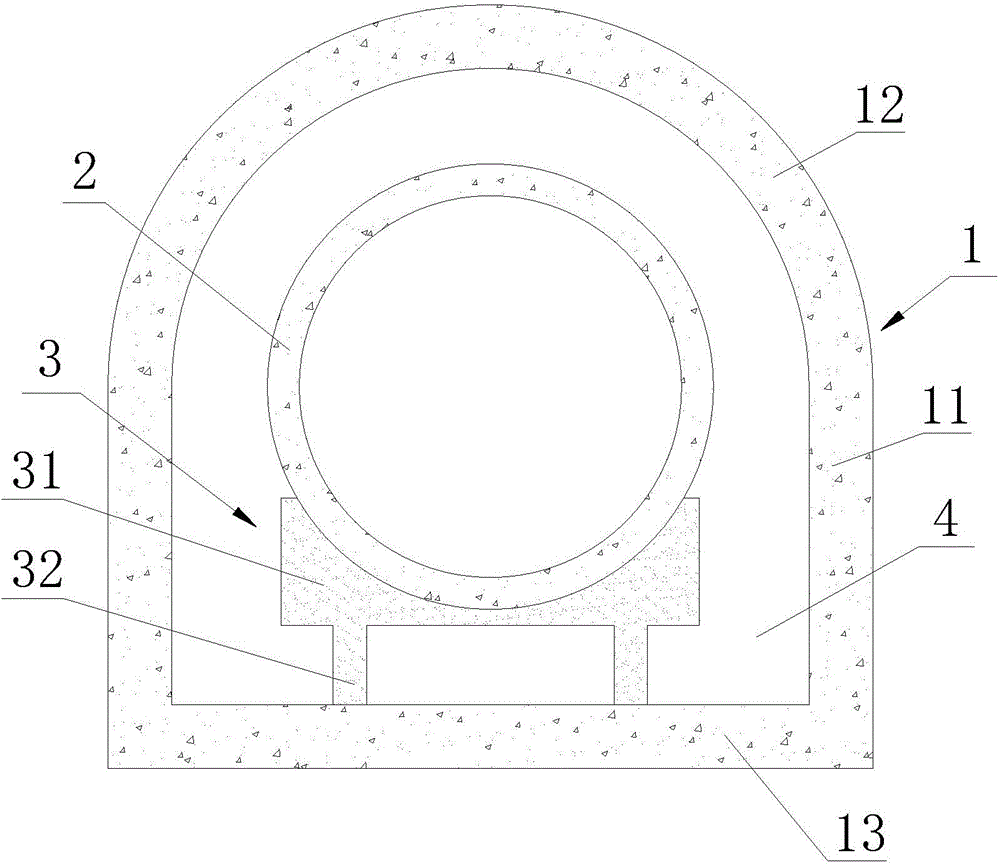

[0027] Such as figure 1 As shown, a water diversion pipe structure in a local material dam according to the present invention includes a lining structure 1, a water diversion pipe 2 and a bracket 3, and the lining structure 1 is composed of a bottom plate 13, a straight line segment 11 and an arc segment 12 , wherein the straight line section 11 is symmetrically fixed on both sides of the bottom plate 13, the arc section 12 is set on the top of the straight line section 11, the water diversion pipe 2 is set inside the lining structure 1, and is supported and fixed by the bracket 3, and the lining structure 1 A deformation space 4 is provided between the water diversion pipe 2 .

[0028] The bracket 3 is composed of a support block 31 and a support foot 32 , wherein the top of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com