Machine vision-based twisted pair pitch measuring method

A measurement method and machine vision technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of high labor intensity, inability to real-time automatic detection of twisted pairs, and large detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

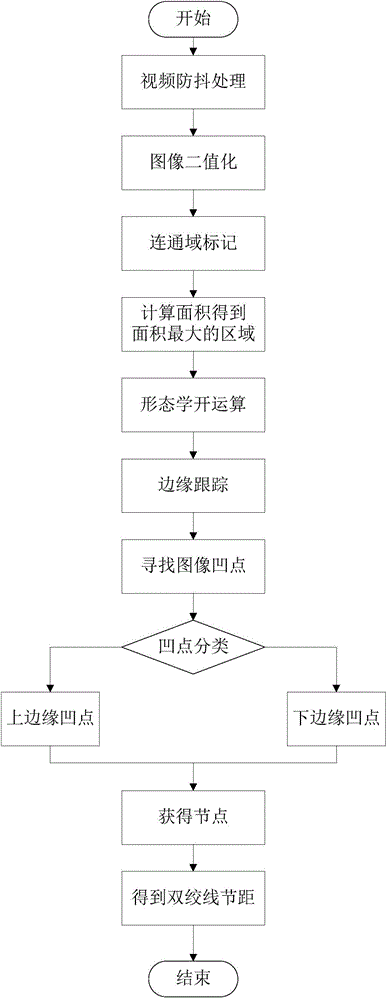

[0038] Below in conjunction with accompanying drawing, the twisted pair pitch measuring method based on machine vision of the present invention is described in detail:

[0039] Step 1: Use the camera to collect twisted pair images;

[0040] Step 2: Perform anti-shake processing on the video in step 1. The algorithm is based on feature matching and affine transformation to obtain each frame of image after anti-shake processing;

[0041] Step 2-1: read the previous frame image as the reference image, and extract scale-invariant feature points;

[0042] Step 2-2: Read the current frame and calculate the feature points, use the affine transformation model to register with the reference image, and use the registered image as the new current frame.

[0043] Step 3: Binarize the image obtained in step 2 according to the set gray threshold to obtain a binary image;

[0044] Step 3-1: Set the gray threshold in the binarization process to be the gray threshold obtained by using the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com