Torsion synchronous intelligent numerical control bender numerical control system

A technology of numerical control system and bending machine, applied in the direction of digital control, electrical program control, etc., can solve the problems of troublesome adjustment of angle, complicated operation, high dependence on technical level of personnel, etc., and achieves high positioning accuracy and high control efficiency. , the effect of control efficiency and accuracy assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

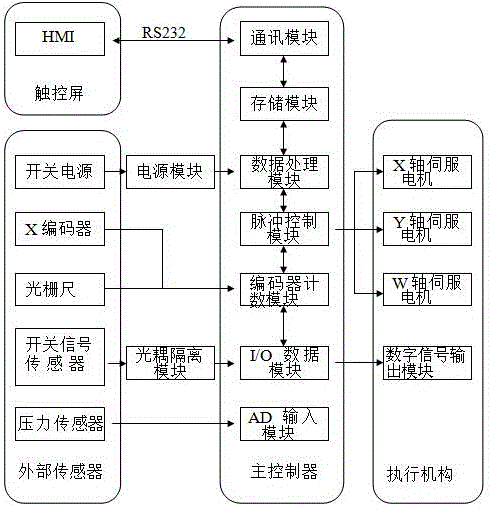

[0015] like figure 1 As shown, the torque synchronous intelligent numerical control bending machine numerical control system of the present invention includes an HMI touch screen, an external sensor, a power supply module, an optocoupler isolation module, a main controller and an actuator. The external sensor is composed of a switching power supply, an X Composed of encoder, grating ruler, switch signal sensor and pressure sensor, the main controller is composed of communication module, storage module, data processing module, pulse control module, encoder counting module, I / O data module, AD input module , the actuator is composed of an X-axis servo motor, a Y-axis servo motor, a W-axis servo motor and a digital signal output module;

[0016] The output end of the HMI touch screen is connected with the input end of the communication module;

[0017] The output end of the switching power supply is connected to the input end of the power module, and the output end of the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com