Method and device for programming track of tour inspection robot

An inspection robot and trajectory planning technology, applied in two-dimensional position/channel control and other directions, can solve problems such as easy deviation from the running trajectory, unstable robot operation, and excessive robot adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

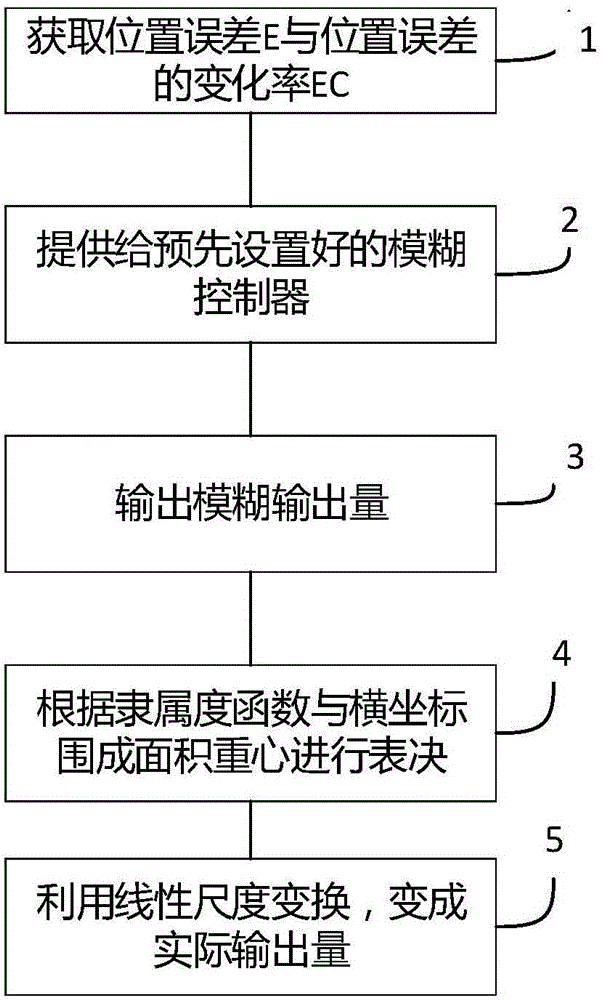

[0059]On the one hand, a method for trajectory planning of an inspection robot is provided, such as figure 1 shown, including:

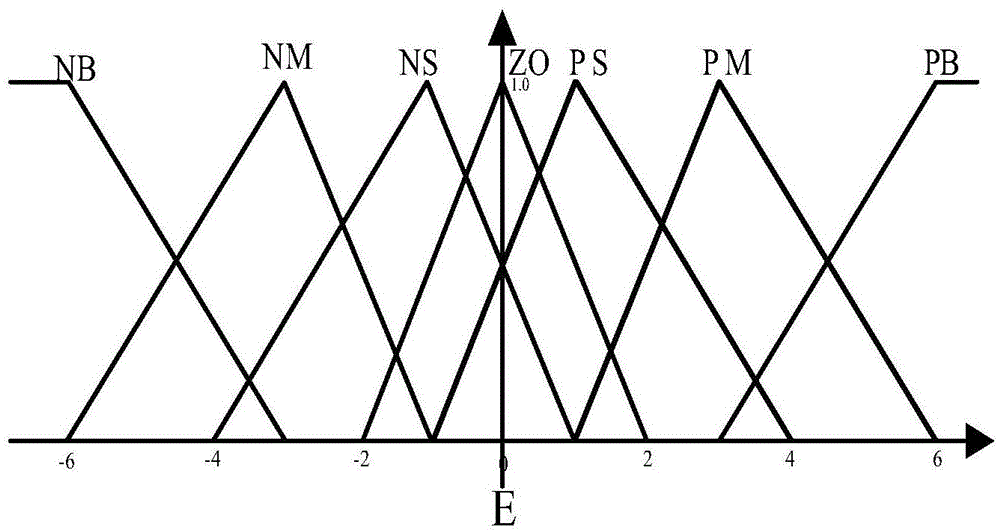

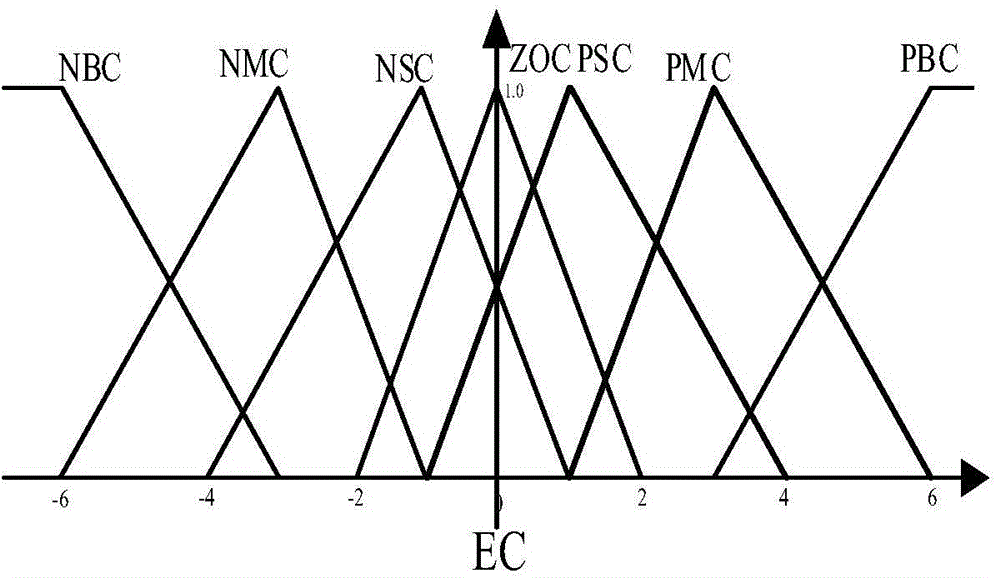

[0060] Step 1: Obtain the position error E of the traveling track and the magnetic track of the inspection robot and the rate of change EC of the position error, as the fuzzy input;

[0061] During the driving process, the inspection robot continuously monitors the deviation between its own running track and the magnetic track, and determines the adjustment angle according to the size of the deviation and the speed of the deviation change, combined with the subsequent steps.

[0062] Step 2: providing the fuzzy input to the preset fuzzy controller;

[0063] Step 3: the fuzzy controller obtains the fuzzy ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com