Loudspeaker net cover production system

A production system and mesh cover technology, applied to electrical components, sensors, etc., can solve the problems of unable to punch the speaker mesh, unable to complete the production of speaker mesh cover in one piece, etc., to reduce labor costs and losses, easy to operate, Accurate punching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

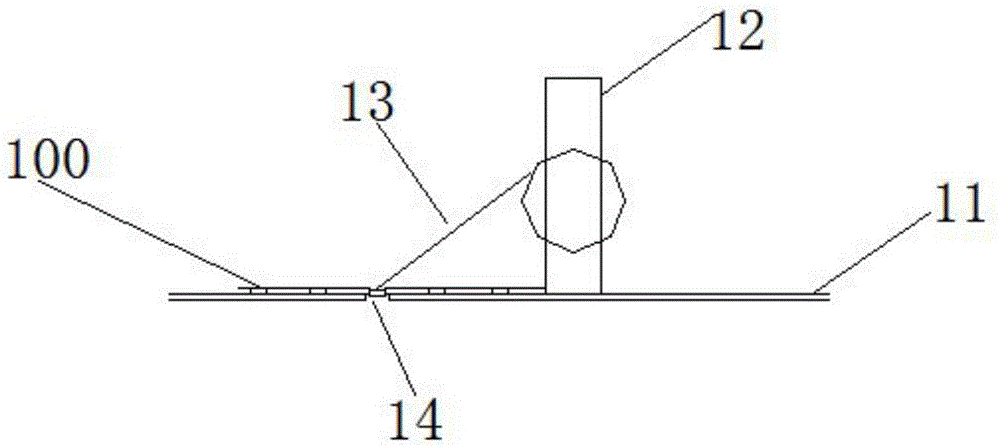

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

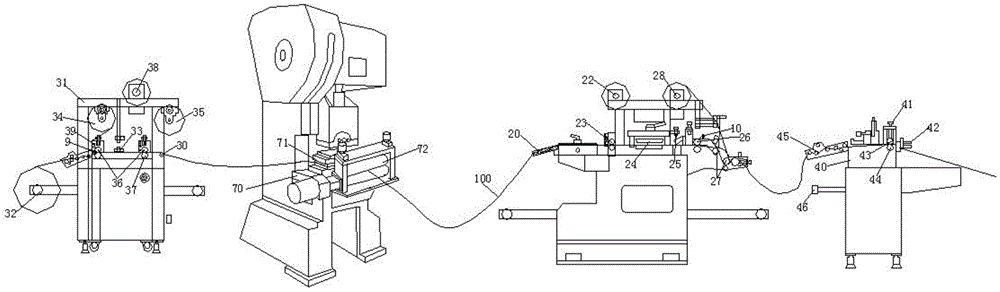

[0022] like figure 1 As shown, the loudspeaker grill production system of the present invention includes a biaxial multi-layer laminating machine, a punching device, an automatic waste discharge die-cutting machine and a cutting machine arranged in sequence.

[0023] The biaxial multi-layer laminating machine includes a frame 31, on which a discharge roller 32, a first laminating unit, a waste discharge unit, a second laminating unit and a transfer roller are sequentially arranged, in order to be able to adjust the discharge The speed of the roller 32 and the degree of tightness of the reel-shaped material belt on the roller 32 are also provided with a tension adjustment device connected to the discharge roller 32, and the tension adjustment device can be a manual wheel or other devices. The first laminating unit includes the first retracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com