Rotary-operation-type electronic component

A technology of rotary operation and electronic components, applied in the direction of contact operating parts, electrical components, circuits, etc., can solve the problems of torque reduction and misoperation of rotary operation, and achieve the effect of easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

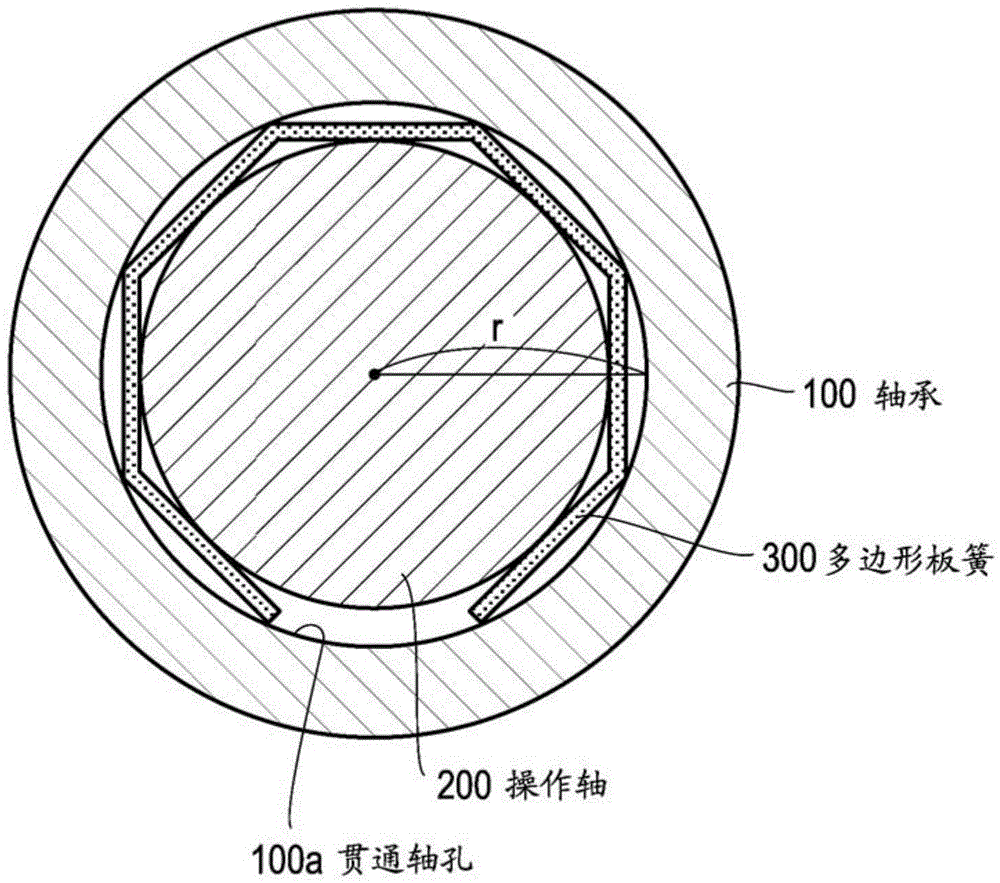

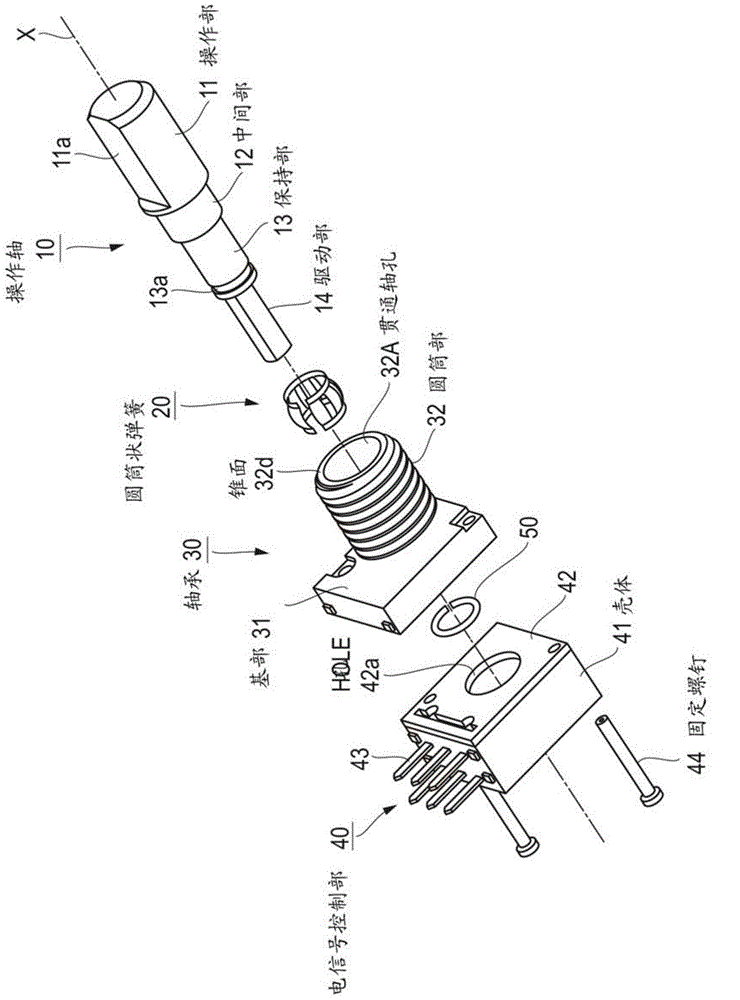

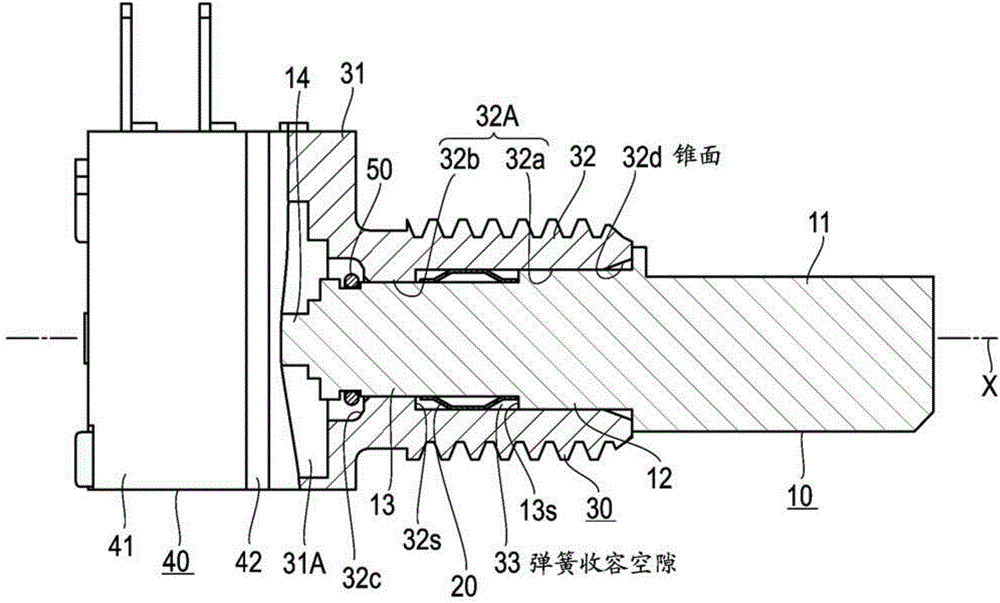

[0027] figure 2 It is a perspective view showing that each part of the rotary operation type electronic component of the present invention is arranged in an exploded manner in the central axis X direction, image 3 It shows a partial cross section of the central axis X direction of the assembled rotary operation type electronic component. The rotary operation type electronic component of the present invention is composed of: a cylindrical operating shaft 10 formed of metal; a cylindrical spring 20 formed of an elastic metal plate and breaking the ring in the axial direction; a bearing formed of metal or resin 30; an electric signal control unit 40; and an anti-drop ring 50 made of a metal material that separates the ring.

[0028] The operating shaft 10 has: a cylindrical operating portion 11 formed by cutting a desired length parallel to the central axis X to form a flat surface 11a; a cylindrical intermediate portion 12 extending coaxially from the operating portion 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com