Hydraulic dust removal device

A dust removal device and water pressure technology, applied in the separation method, filtration separation, dispersed particle separation, etc., can solve the problems of generating dust and affecting the working site environment, etc., and achieve the effect of reasonable structure design, obvious dust removal effect and optimized working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

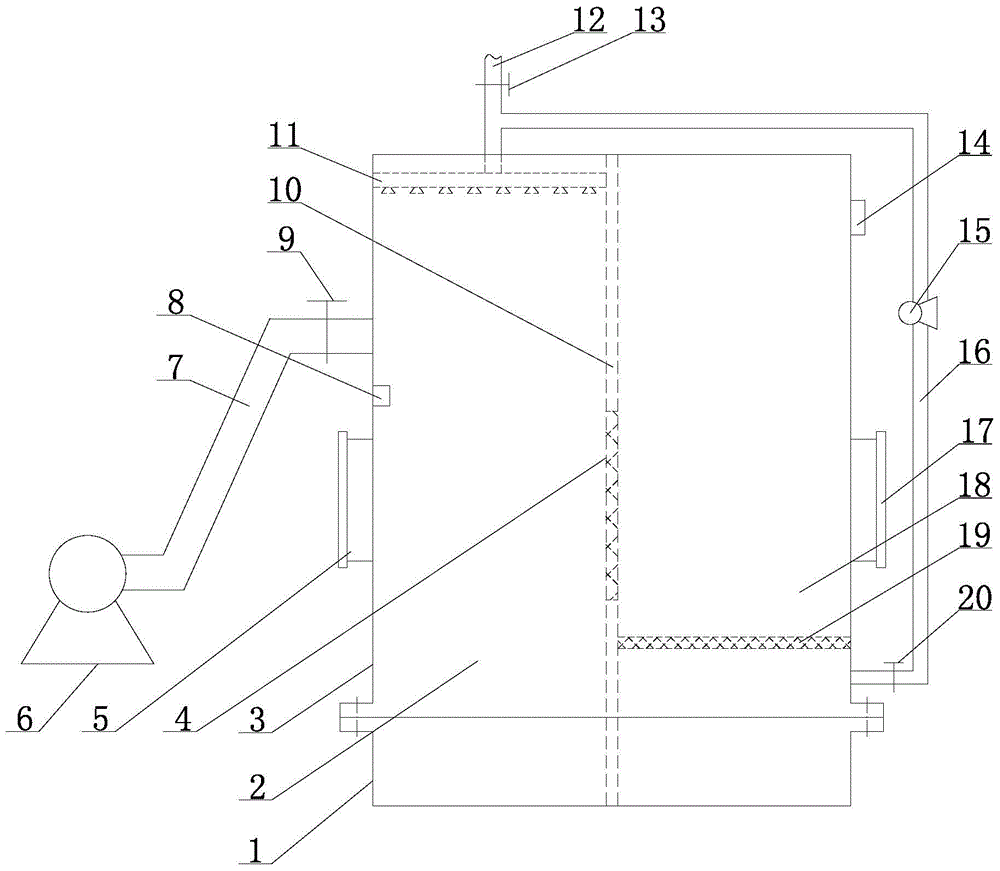

[0015] Such as figure 1 Shown, this water pressure dedusting device comprises induced draft fan 6 and water pressure dedusting box, vertical dividing plate 10 is set in the water pressure dedusting box, and the middle and upper part of dividing plate 10 is provided with primary filter screen 4, and dividing plate 10 divides hydraulic pressure The dust removal box is divided into two chambers: the dust removal chamber 2 and the drainage chamber 18. The induced draft fan 6 is connected to the dust removal chamber 2 through the air pipe 7. The air intake valve 9 is installed on the air pipe 7. The upper end of the dust removal chamber 2 is provided with a spray system 11. The water inlet of the shower system 11 is connected to the water supply pipe 12, the water inlet valve 13 is installed on the water supply pipe 12, and the secondary precision filter screen 19 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com