Protruded spiral groove type swirler

A technology of helical groove and cyclone, which is applied in the direction of cyclone devices, devices whose axial direction of cyclone can be reversed, etc., can solve the problems of separation efficiency influence and unsatisfactory effect, so as to reduce overflow and run rough, and prevent Unreasonably flipped, widely used effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

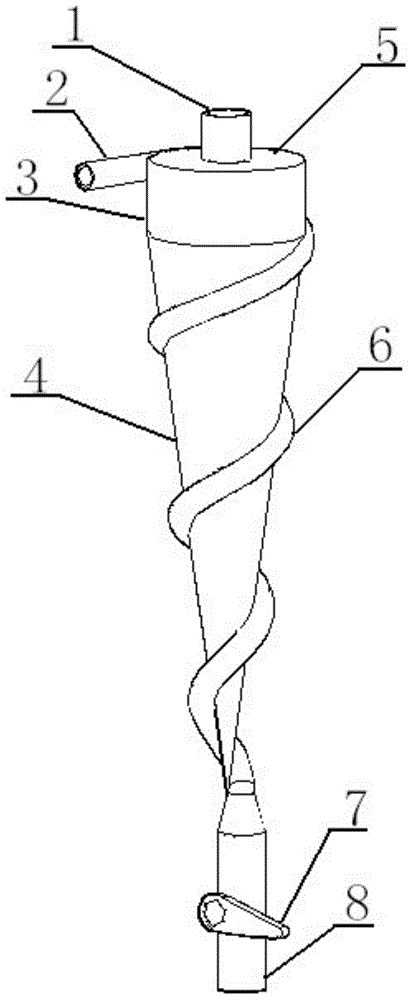

[0020] Such as figure 1 As shown, the cyclone of the present invention is an internal hollow structure, the top is a hollow cylindrical section 3, the bottom is a hollow conical section 4, the bottom surface of the cylindrical section 3 is connected to the bottom surface of the conical section 4, and the bottom of the conical section 4 is At the closed end, an overflow pipe 1 is connected to the center of the upper surface of the cylindrical section 3 , and the upper surface of the cylindrical section 3 can also be designed as a detachable top cover 5 , and the overflow pipe 1 is installed at the center of the top cover 5 . The axial centerlines of the overflow pipe 1, the cylindrical section 3 and the conical section 4 are collinear.

[0021] The feed pipe 2 communicates with the upper end of the cylindrical section 3, and is inclined downward relative to the cylindrical section 3 and is tangent to the cylindrical section 3. The downward inclination angle of the feed pipe 2 i...

Embodiment 2

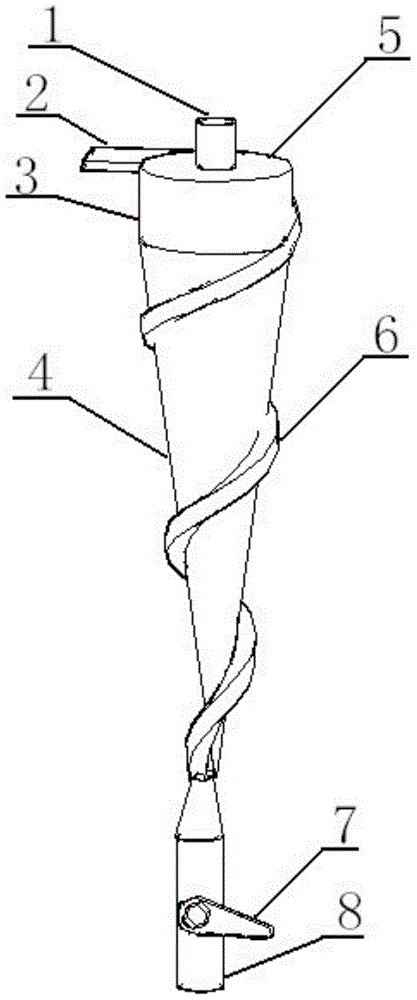

[0023] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that the feeding pipe 2 of the present embodiment enters the cylindrical section 3 and forms an angle of 15-60° with the horizontal line and continues to extend downward along the wall of the cyclone and form a square shape. Protruding from the wall of the device is the spiral groove 6; that is, the cross-sectional shape of the spiral groove 6 in this embodiment is rectangular. Others are identical with embodiment one.

[0024] Working principle of the present invention is:

[0025] When the medium (material) to be separated enters the cyclone from the feed pipe 2, relying on the difference in the density of the light and heavy phases or the difference in the particle size between the coarse and fine particles, the centrifugal force and the drag force are different, forming an inner and outer two phases in the cyclone. Vortex, the heavy phase is thrown into the spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com