Bar stock fine blanking storage trolley with recycling function and using method thereof

A strip material and material storage technology, applied in the field of material storage trolley, can solve the problem of inability to recycle strip material, and achieve the effect of strong recycling function, reduced labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

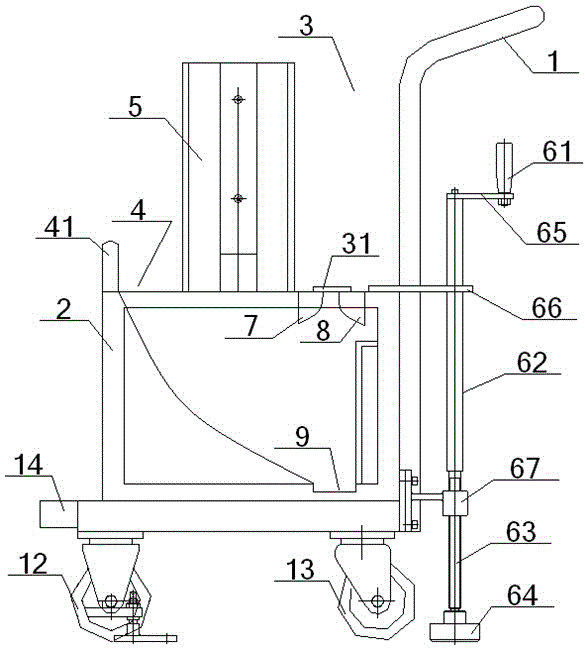

[0050] see figure 1 , a fine-blanking strip stocker with recovery function, comprising a handrail 1, a vehicle bottom frame 2, an isolation seat 5, a recovery seat 41 and wheels, the right side of the vehicle bottom frame 2 is connected to the handrail 1, The bottom of the underbody frame 2 is provided with mutually symmetrical front wheels 12 and rear wheels 13, and the rear wheels 13 are arranged near the armrest 1;

[0051] The top of the underbody frame 2 is vertically connected with an isolation seat 5, and a strip groove 3 is sandwiched between one side of the isolation seat 5 and the upper part of the inner side of the armrest 1 to hold the strip material 31, and the inner side of the armrest 1 The lower part of the side is connected with the right side of the vehicle underframe 2, and the recovery groove 4 is clamped between the other side of the isolation seat 5 and the recovery seat 41, and the bottom of the recovery seat 41 is connected with the top of the vehicle u...

Embodiment 2

[0057] see figure 1 and figure 2 , the basic content is the same as in Example 1, the difference is that:

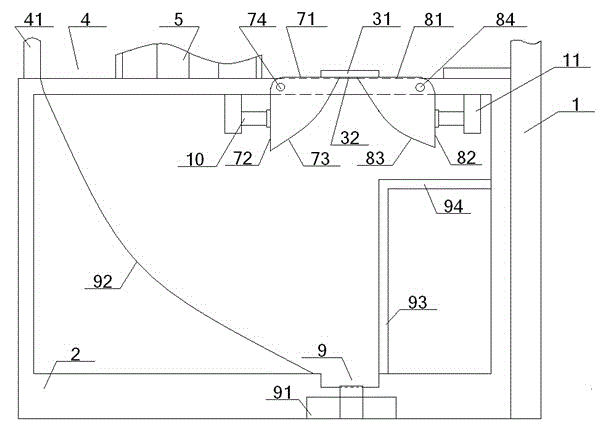

[0058]The strip fine blanking storage vehicle also includes a feeding tank 9, a feeding motor 91, a left feeding tongue 7 and a right feeding tongue 8; the bottom of the vehicle bottom frame 2 is provided with a feeding tank 9, and the The top of the left side of feeding tank 9 is connected with the bottom of feeding arc 92, and the top of this feeding arc 92 is connected with the junction of recovery seat 41 and recovery tank 4, and feeding arc 92 is The arc-shaped slideway of concave structure, the top of the right side of described supplementary chute 9 is flush with the bottom of the guide bar 93 of vertical structure, and the top of this guide bar 93 is connected with the undercarriage by horizontal bar 94 The inner wall on the right side of 2 is fixedly connected, and a feeding motor 91 is provided at the bottom of the feeding tank 9; the left feeding tongue 7 i...

Embodiment 3

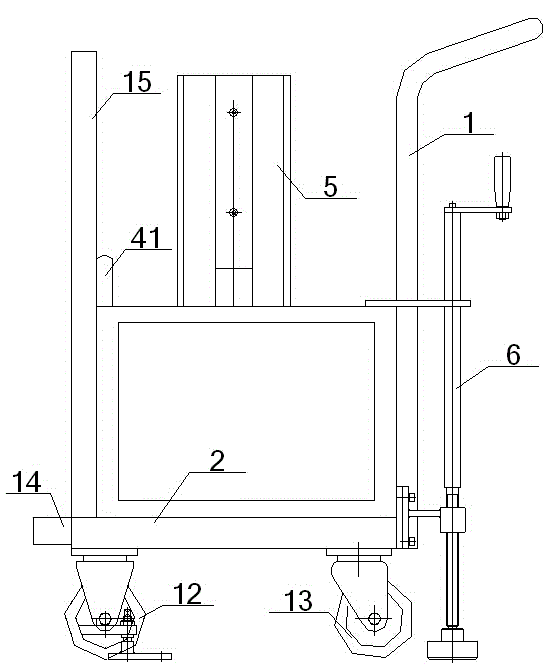

[0061] see figure 1 and image 3 , the basic content is the same as that of Embodiment 1, the difference is that: the outer wall of the left side of the underbody frame 2 is connected with the inner side of the block seat 15, and the bottom of the block seat 15 is connected with the bottom of the underbody frame 2 The top surface of the block is vertically connected, and the top of the block seat 15 is set higher than the top of the isolation seat 5, and the block block 15 is erected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com