Casting gap repairing device

A gap and equipment technology, applied in the field of casting gap repair equipment, can solve problems such as toxicity, curing the symptoms and curing the root cause, and failing to achieve the repair effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

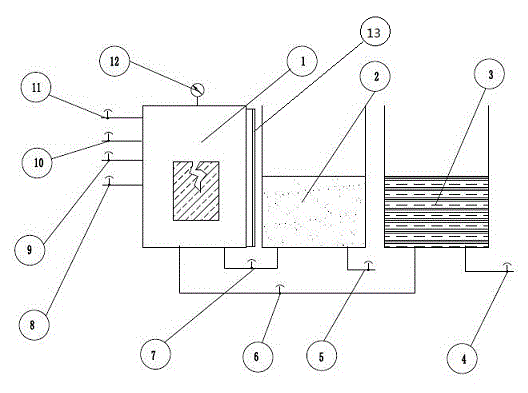

[0014] Such as figure 1 As shown, a casting gap repairing device of the present invention has a closed container 1 that can be vacuumed, and the closed container 1 can hold the castings that need to be repaired, and is the core component of the casting repair. The closed container 1 communicates with the permeate container 2 and the cleaning water container 3 respectively, and the sizes of the permeate container 2 and the cleaning water container 3 are respectively similar to those of the closed container 1 . A water-soluble sodium silicate solution is contained in the permeate container 2 . The connecting pipe between the airtight container 1 and the permeate container 2 is provided with a permeate valve 7 , the permeate container 2 is provided with a permeate discharge pipe, and the permeate discharge pipe is provided with a permeate discharge valve 5 . The connecting pipe between the airtight container 1 and the cleaning water container 3 is provided with an inlet and outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com