Quick healant with low viscosity and high performance for concrete structure

A high-performance concrete and low-viscosity technology, which is applied in the field of chemical building materials, can solve the problems of long curing time, large shrinkage deformation, and high requirements for preparation conditions, and achieves simple preparation and construction operations, low loss rate of mechanical strength, and economical reduction. loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

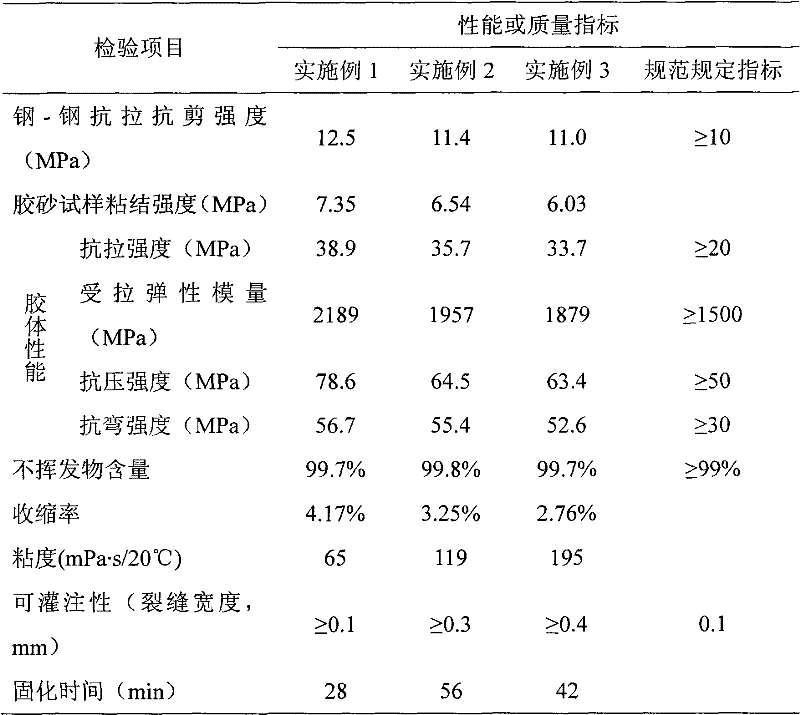

Examples

Embodiment 1

[0030] (1) low-viscosity high-performance concrete structure rapid repair agent comprises following components by weight parts:

[0031] Component 1: methyl methacrylate, 100 parts;

[0032] Component 2: butyl methacrylate, 28 parts;

[0033] Component 3: benzoyl peroxide, 3.0 parts;

[0034] Component 4: epoxy resin, 16 parts;

[0035] Component 5: KH-570, 10 parts;

[0036] Component 6: methacrylic acid, 3.5 parts;

[0037] Component 7: Dimethylaniline, 1.2 parts;

[0038] Component 8: Portland cement, 0 parts.

[0039] (2) Preparation of low-viscosity high-performance concrete structure rapid repair agent

[0040] Mix and stir epoxy resin, methyl methacrylate, butyl methacrylate, benzoyl peroxide, KH-570, and methacrylic acid at room temperature until the solution becomes transparent, then react at 80°C for 25 minutes. After the viscosity reaches 65mPa·s, it is cooled to room temperature, and finally the curing material dimethylaniline is added in proportion to obtai...

Embodiment 2

[0042] (1) low-viscosity high-performance concrete structure rapid repair agent comprises following components by weight parts:

[0043] Component 1: methyl methacrylate, 100 parts;

[0044] Component 2: butyl methacrylate, 32 parts;

[0045] Component 3: benzoyl peroxide, 3.3 parts;

[0046] Component 4: epoxy resin, 20 parts;

[0047] Component 5: KH-570, 14 parts;

[0048] Component 6: methacrylic acid, 3.7 parts;

[0049] Component 7: Dimethylaniline, 1.0 part;

[0050] Component 8: Portland cement, 10 parts.

[0051] (2) Preparation of low-viscosity high-performance concrete structure rapid repair agent

[0052]Mix and stir epoxy resin, methyl methacrylate, butyl methacrylate, benzoyl peroxide, KH-570, and methacrylic acid at room temperature until the solution becomes transparent, then react at 81°C for 22 minutes. After the viscosity reaches 45mPa·s, cool to room temperature, add inorganic fillers and disperse under ultrasonic for 15 minutes, the measured viscosi...

Embodiment 3

[0054] (1) low-viscosity high-performance concrete structure rapid repair agent comprises following components by weight parts:

[0055] Component 1: methyl methacrylate, 100 parts;

[0056] Component 2: butyl methacrylate, 35 parts;

[0057] Component 3: benzoyl peroxide, 3.8 parts;

[0058] Component 4: epoxy resin, 15 parts;

[0059] Component 5: KH-570, 19 parts;

[0060] Component 6: methacrylic acid, 4.0 parts;

[0061] Component 7: dimethylaniline, 0.8 parts;

[0062] Component 8: Portland cement, 20 parts.

[0063] (2) Preparation of low-viscosity high-performance concrete structure rapid repair agent

[0064] Mix and stir epoxy resin, methyl methacrylate, butyl methacrylate, benzoyl peroxide, KH-570, and methacrylic acid at room temperature. After the solution becomes transparent, the reaction time at 83°C is After 21 minutes, after the viscosity reaches 40mPa·s, cool to room temperature, add inorganic fillers and disperse under ultrasonic for 20min, the measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com