Drilling jig for drilling of outer wallboard of forklift

A siding and forklift technology, applied in the field of machinery, can solve the problems of reducing the processing efficiency, the weight of the outer siding, affecting the processing, etc., to achieve the effects of stable processing quality, eliminating the scribing process and improving the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

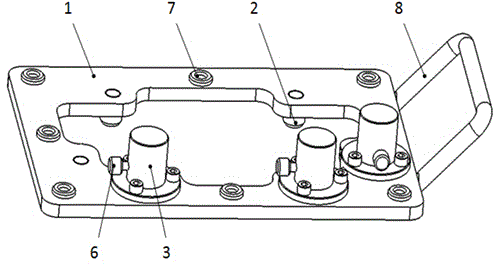

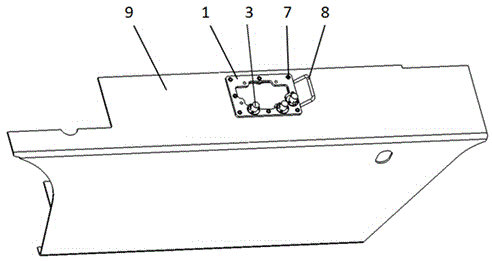

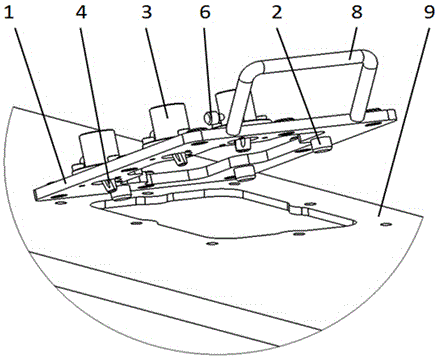

[0029] like Figure 1-4 Shown, a kind of drilling formwork that is used for forklift outer wall plate drilling comprises drilling formwork 1, and the center hole corresponding to the installation square hole on the outer wall plate 9 is opened in the middle of described drilling formwork 1, and the drilling formwork that is positioned at the center hole outside The template 1 is provided with a drill sleeve hole 13 corresponding to the position of the threaded hole on the outer wall plate, and the drill sleeve hole 13 is provided with a drill sleeve 7; the bottom end surface of the drill template 1 is provided with a positioning pin 2, which is different from The drilling template 1 on one side of the positioning pin 2 is provided with an inclined elastic body.

[0030] like Figure 5 , 6 As shown, the inclined-plane elastic body includes a base 3 provided with a guide hole 31, and the inclined-plane mandrel 4 is movably sleeved in the guide hole 31, and the inside of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com