Novel automatic electric welding machine with auxiliary discharging mechanism

An auxiliary discharge and electric welding machine technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of electromagnetic interference of the power grid, poor welding quality, low power utilization efficiency, etc., and achieve the effect of slowing down the performance index requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

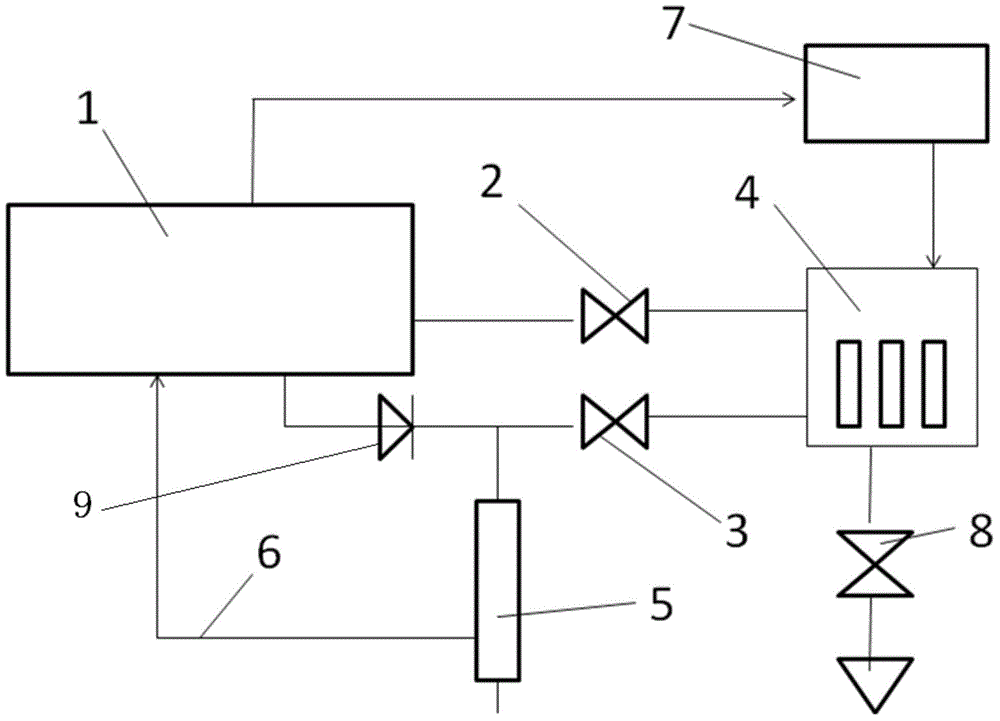

[0033] Preferred embodiment one: the welding machine host 1 with ordinary automatic control is applied, and the energy storage device 4 and the energy storage device controller 7 are configured to it, wherein the energy storage device 4 is a set of power capacitors with a switch matrix to control the power capacitors The energy storage device controller 7 adopts a single-chip microcomputer system to realize the connection form of the energy storage device. The energy storage device controller 7 can carry out RS485 serial communication with the overall controller of the welding machine host 1 and accept the control instructions of the whole machine. In addition to establishing a communication connection with the welding machine host 1, the energy storage device 4 is also connected to the welding machine host 1 and the welding torch 5 through a charging switch 2 and a discharging switch 3, and can be discharged to the ground through a ground discharge switch 8. The charge switch 2...

Embodiment 2

[0036] Preferred embodiment two: the welding machine host 1 with automatic control is adopted, the energy storage device 4 and its controller 7 are configured, and the charge and discharge switches are the same as in the first embodiment. The main machine 1 of the welding machine adopts an intermittent working mode of continuously welding three welding points, intermittently, and then continuously welding three welding points. The energy storage device 4 is configured into three groups through the energy storage device controller 7, and the charging switch 2 is turned on during the intermittent period of the welding machine to charge the three groups of energy storage elements. After that, each welding spot is welded by the energy storage device The controller 7 controls a certain group of energy storage components to perform discharge assistance. After the three solder joints are welded, the three groups of energy storage components are charged again in an intermittent stage.

...

Embodiment 3

[0038] Preferred embodiment three: the welding machine host 1 with automatic control is adopted, the energy storage device 4 and its controller 7 are configured, and the energy storage element is a solar battery pack. When the solar energy is sufficient, the solar battery is always charged and fully charged In the state, the solar cells are divided into at least two groups and alternately perform auxiliary discharge work.

[0039] The characteristic of this embodiment is the application of new energy devices and the corresponding omission of the charging switch 2, but the nature of the auxiliary welding machine has not fundamentally changed. This embodiment can be regarded as the basic idea of the present invention. A simple modification after the production of new technologies and new devices can also achieve good results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com