Glass carrying fixture air supply system

A gas supply system and glass technology, applied in manufacturing tools, transportation and packaging, metal processing equipment, etc., can solve problems such as prone to errors, limited gas volume, poor safety, etc., achieve the effect of ample time and preparation, and reduce safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

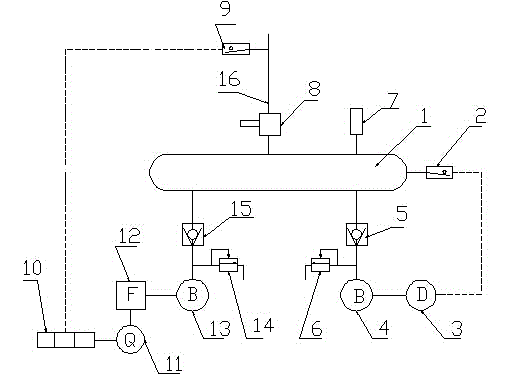

[0008] In conjunction with accompanying drawing, the specific embodiment of the present invention is:

[0009] The air supply system for a glass handling fixture includes an air storage tank (1), characterized in that: the air outlet end of the air compressor A (1) passes through the one-way valve A (5) and the air storage tank (1) The interior is connected; the air compressor A (1) is driven by the motor (3), and the pressure relay A (2) is set on the air storage tank (1), and the pressure relay A (2) stores gas through induction The pressure change in the tank (1) controls the start or stop of the motor (3), and a safety valve (5) is installed on the pipeline between the air outlet of the air compressor (1) and the check valve (5). ), the air outlet port of the air compressor B (13) communicates with the inside of the air storage tank (1) through the check valve B (15); the air compressor B (13) is driven by the fuel engine (12), so The fuel engine described above is starte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com