Three-finger mechanical gripper with variable structure

A manipulator claw and configuration technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of large volume and high maintenance cost, and achieve the effect of small overall structure size, low maintenance cost, and reduced requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

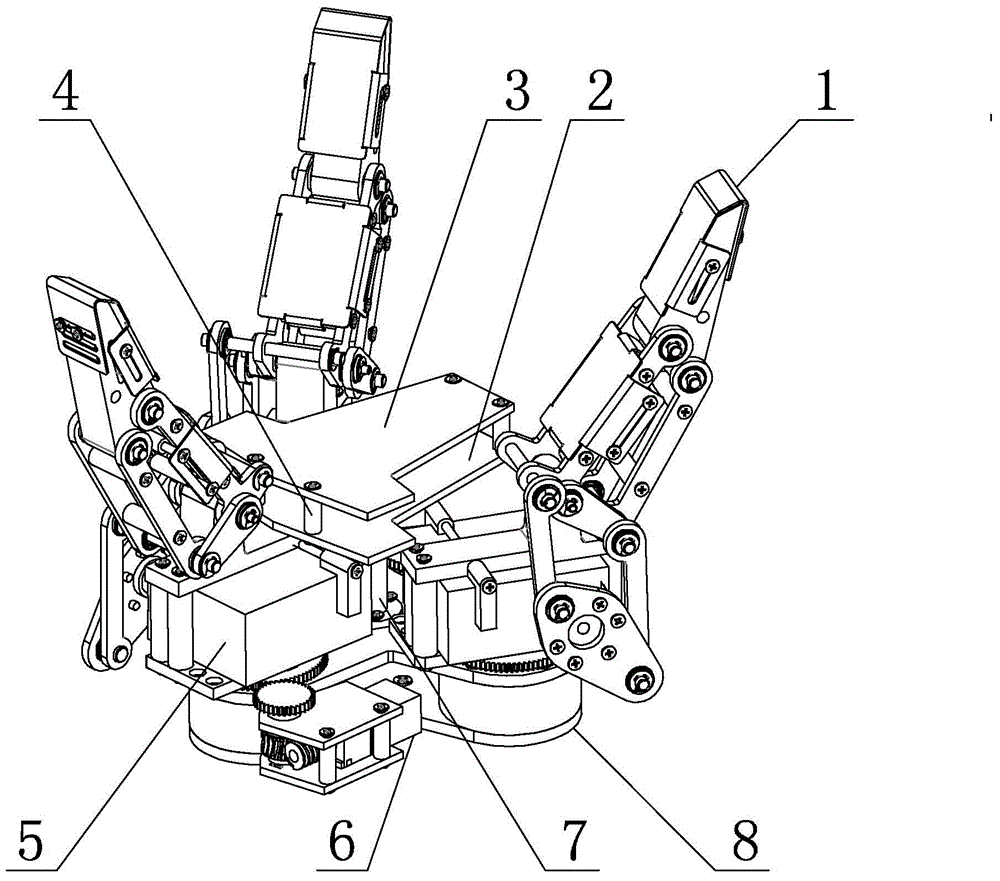

[0017] Specific implementation mode one: as Figure 1~6 As shown, the variable-configuration three-finger mechanical gripper of this embodiment includes a palm, a rotating base 8, a central cylinder 7, three rotating shafts 21, three rotating tables 20, three finger bottom motors 6, and three turbines. 23, three worms 24, three large spur gears 22, three small spur gears 25 and three fingers 1, three fingers 1 are arranged on the rotating base 8, the palm is composed of a flat plate 2 under the palm, a flat plate 3 on the palm and a plurality of Composed of connecting cylinders 4, the palm upper plate 3 is fixed on the upper end surface of the palm lower plate 2 through a plurality of connecting cylinders 4, the palm upper plate 3 is arranged in parallel with the palm lower plate 2, and the lower end of the palm lower plate 2 is fixed by the central cylinder 7. Installed at the center of the upper end surface of the rotating base 8;

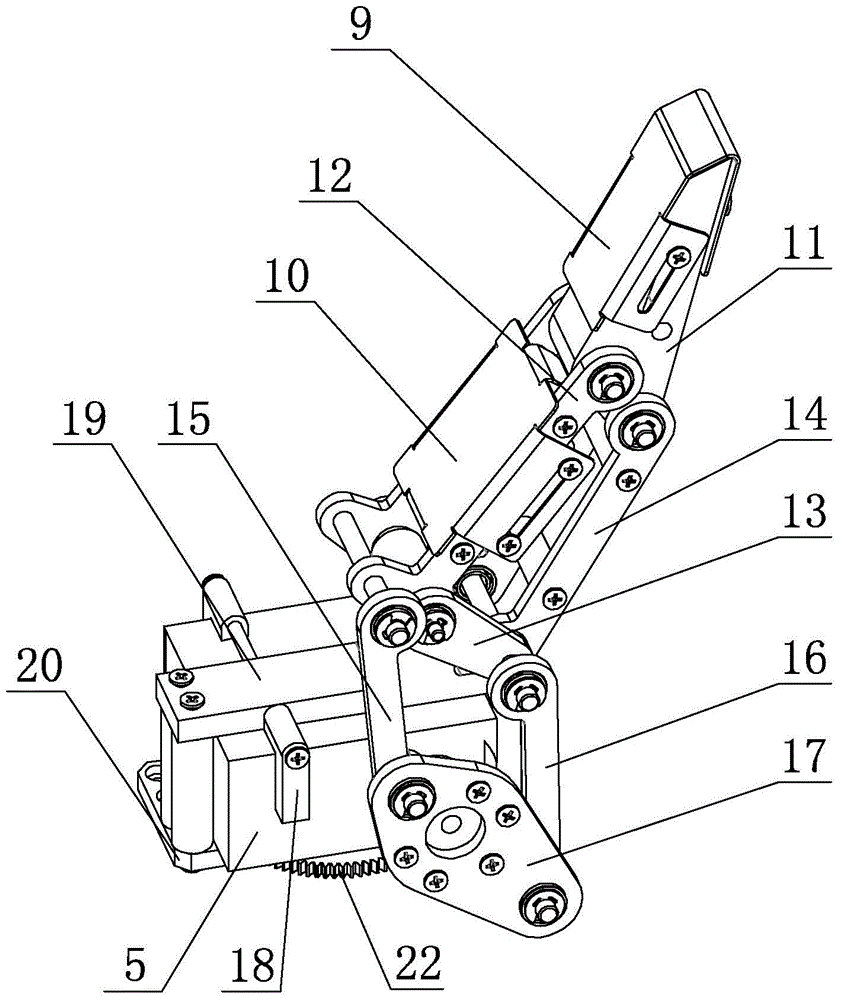

[0018] Each finger comprises a first knuc...

specific Embodiment approach 2

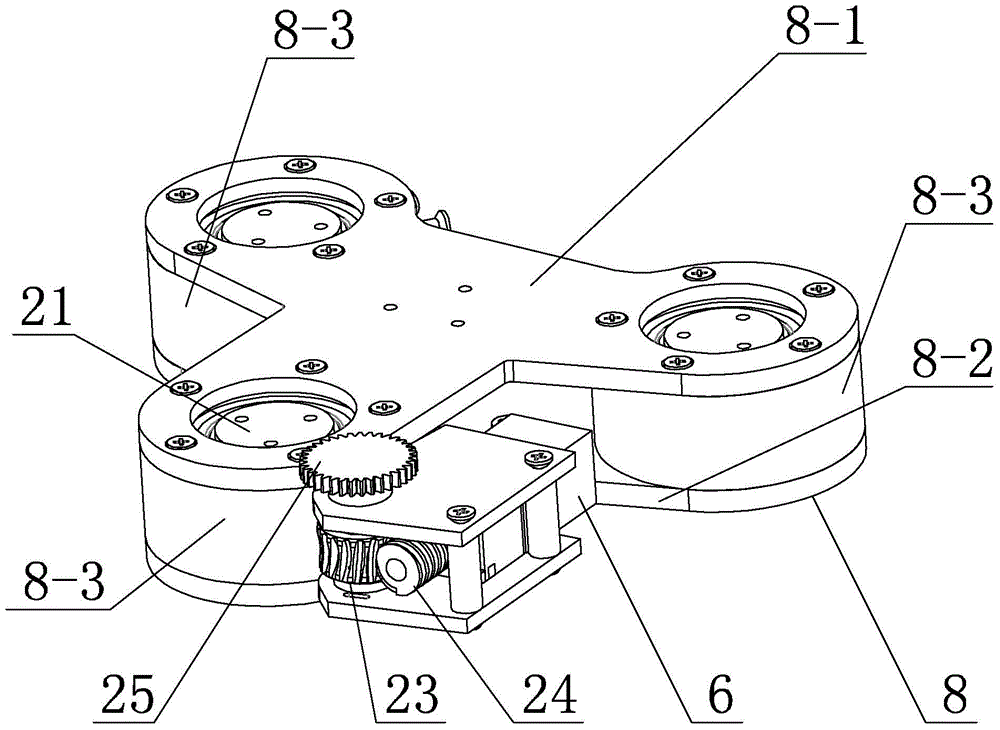

[0021] Specific implementation mode two: as image 3 As shown, the rotating base 8 in this embodiment includes an upper rotating platform 8-1, a lower rotating platform 8-2 and three bearing sleeves 8-3, and the upper rotating platform 8-1 and the lower rotating platform 8-2 are arranged in parallel , three bearing sleeves 8-3 are evenly distributed and fixed between the upper rotating platform 8-1 and the lower rotating platform 8-2, and a rotating shaft 21 is installed in each bearing sleeve 8-3. With such a design, the pointing of each finger can be flexibly adjusted, thereby increasing the diversity of claw configurations. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: as figure 2 As shown, the three-fingered robotic gripper in this embodiment also includes three first knuckle sets 9 , and one first knuckle set 9 is installed on the first knuckle 11 . Such a design can increase the frictional force when the fingers are in contact with the object to ensure the stability of grasping; and can avoid the possible surface wear of the fingers when they are in rigid contact with the object. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com