Vehicle accumulator monitoring method and system

A battery and battery voltage technology, applied in the field of automotive battery monitoring methods and systems, can solve problems such as excessive self-discharge, failure to charge, difficult battery, etc., to achieve the effect of avoiding insufficient electrolyte and ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

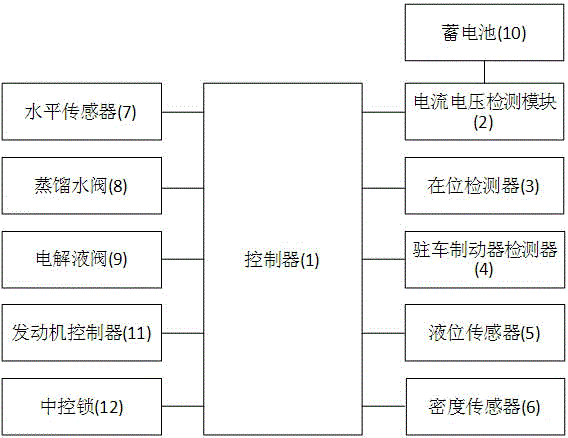

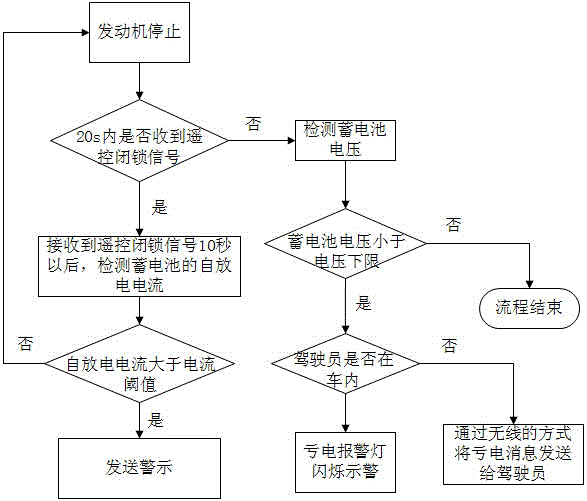

[0031] Embodiment: a kind of automobile storage battery monitoring system of the present embodiment, such as figure 1 As shown, it includes controller 1, current and voltage detection module 2, presence detector 3, parking brake detector 4, liquid level sensor 5, density sensor 6, level sensor 7, distilled water valve 8 and electrolyte valve 9. The controller is respectively connected with the presence detector, the current and voltage detection module, the parking brake detector, the liquid level sensor, the density sensor, the level sensor, the distilled water valve, the electrolyte valve, the engine controller 11 and the central lock 12. The current and voltage detection module is connected to the positive pole and the negative pole of the storage battery 10 . Both the distilled water valve and the electrolyte valve are electronically controlled valves. The liquid level sensor and density sensor are installed inside the battery, the parking brake detector is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com