Hoisting and conveying square bucket for building construction and manufacturing method thereof

A technology of building construction and manufacturing method, which is applied in the field of hoisting and transporting square buckets, can solve problems such as inconvenient loading and unloading, poor hoisting stability, and influence on construction efficiency, so as to prevent material from scattering, improve overall bearing capacity, reduce The effect of labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

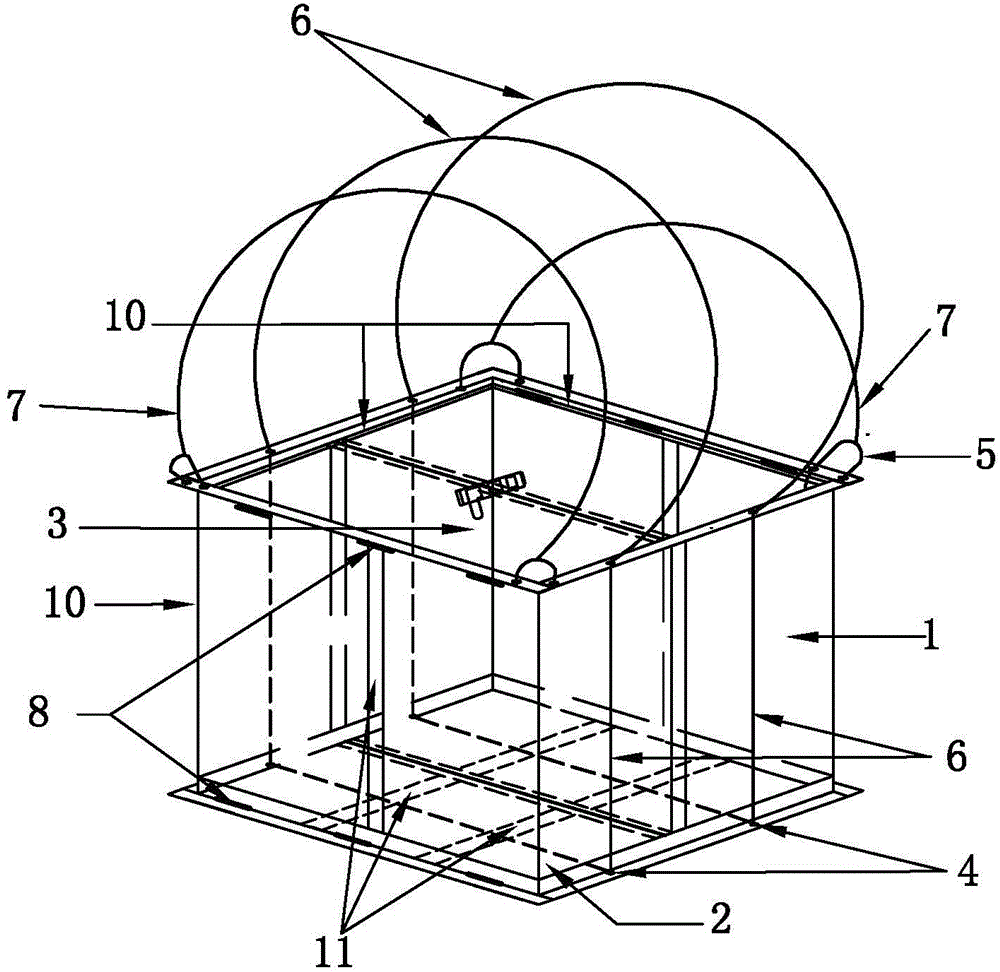

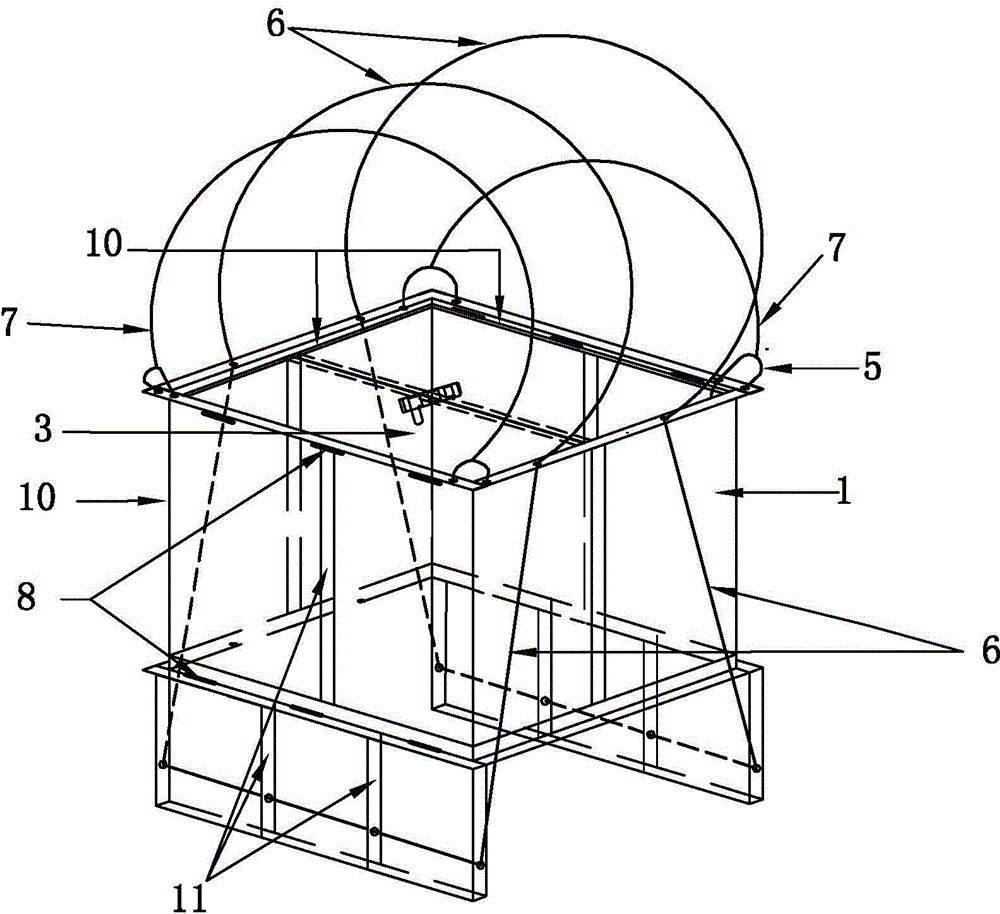

[0046] A lifting square bucket for building construction, such as figure 1 , figure 2 As shown, the lifting square bucket for building construction includes a bucket body 1 and a floor door leaf 2, and the floor door leaf 2 is hinged to the bottom of the bucket body 1 through a hinge 8, so that the floor door leaf 2 has the function of opening and closing; the bucket body 1 It is a cube composed of steel keel skeleton and steel plate welded, and each edge has a steel keel 10;

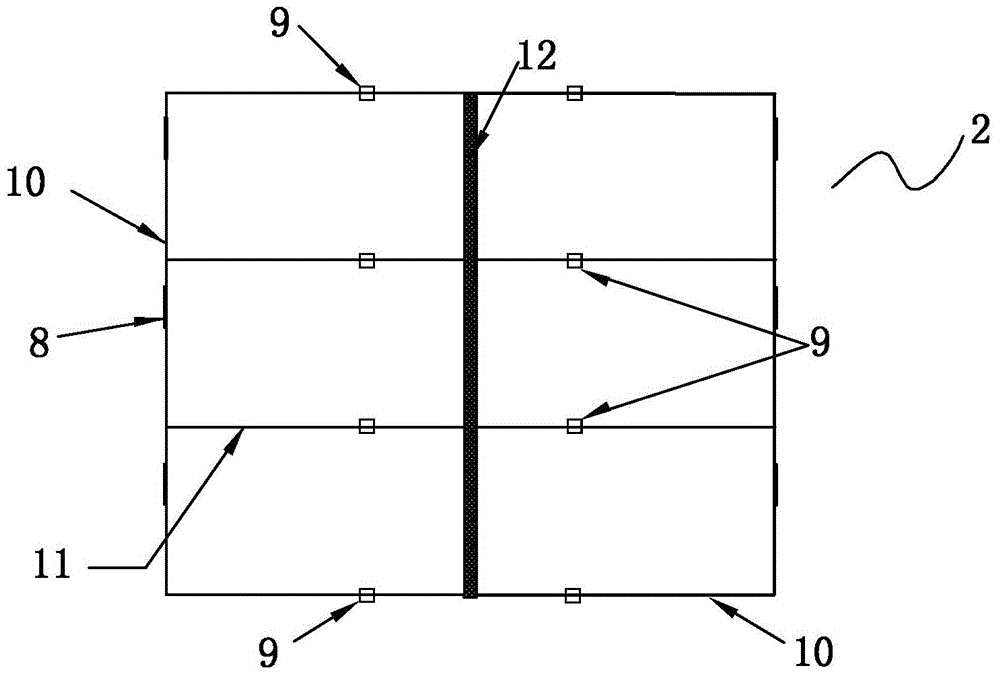

[0047] The base plate door leaf 2 is composed of two steel plate doors formed by welding steel plates and steel keels, and the position of the base plate door leaf hinge is set on the steel keel corresponding to the lower part of the bucket body;

[0048] The outer side of the bucket body 1 and the steel keel on the corresponding two sides of the floor door leaf 2 are provided with small rope holes 4, and two hoisting steel wire ropes 6 used for hoisting materials pass through the small rope holes 4 r...

Embodiment 2

[0061] A method for manufacturing a lifting square bucket for building construction, which is the manufacturing method for a lifting square bucket for building construction described in Embodiment 1. By optimizing and improving the structure of the hanging bucket, the hanging bucket becomes a usable An exquisite bucket that is matched with a steel wire rope to control the opening and closing of the bottom plate; its manufacturing method includes the following steps:

[0062] A. Making the bucket body and parts:

[0063] A1. Making the bucket body: use Fangtong as the steel keel and weld it into a steel keel skeleton; the bucket body 1 is welded with a steel keel skeleton and steel plate to make a three-dimensional shape or an inverted trapezoidal shape with a large upper mouth and a smaller lower mouth;

[0064] A2. Make the bottom door leaf 2 and bucket cover 3:

[0065] ① The steel keel skeleton of the floor door leaf 2 and the bucket cover 3 is made by square welding;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com