Fluorosilicone rubber composition

A technology of fluorosilicone rubber and composition, applied in the field of fluorosilicone rubber composition, to achieve the effect of less strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

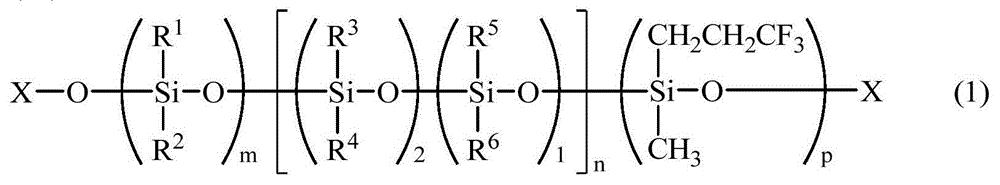

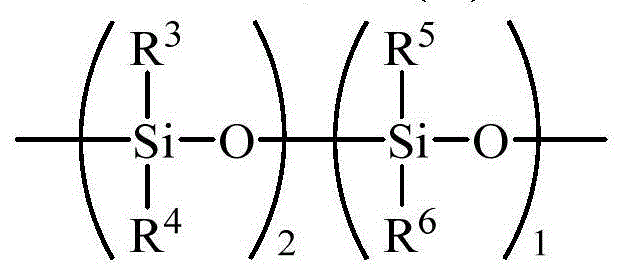

Method used

Image

Examples

Embodiment 1 and 2 and comparative example 1 and 2

[0074] Prepare the fluorosilicone raw rubber (vinyl content: 0.13mol%) of formula (10) and the fluorosilicone raw rubber (vinyl content: 0.0125mol%) of formula (11) as shown in Table 1. A raw rubber blend. As shown in Table 1, to 100 parts by weight of various raw rubber blends, 45 parts by weight of 2 Dry-process silica (Aerosil 130, Nippon Aerosil Co., Ltd.) and 10 parts by weight of diphenylsilanediol as a dispersant per gram of specific surface area were uniformly kneaded, heat-treated at 150° C. for 4 hours, and The fluorosilicone base compound is obtained by milling on a two-roll mill for mastication and plasticization. The base compounds were named A, B, C and D.

[0075]

[0076] To 100 parts by weight of each base compound was added 1 part by weight of 2 Cerium oxide / g specific surface area and 0.8 parts by weight of a paste containing 80% by weight of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane. These were mixed on a two-roll mill until homogeneous. Four flu...

Embodiment 3 and comparative example 3 and 4

[0084] As shown in Table 3, the fluorosilicone raw rubber (vinyl content: 0.25mol%) of the formula (12) and the fluorosilicone raw rubber (vinyl content: 0.0125mol%) of the formula (11) or the formula (13) were prepared. Three raw rubber blends of fluorosilicone raw rubber (vinyl content: 0.011 mol%). Add 40 parts by weight to 100 parts by weight of each raw rubber blend with 90m 2 / g or 200m 2 Dry-process silica (Aerosil 90 or Aerosil 200, Nippon Aerosil Co., Ltd.) of specific surface area per g and 10 parts by weight of diphenylsilanediol as a dispersant were uniformly kneaded and heat-treated at 150°C for 4 Hours, and knead on a two-roll mill to masticate and plasticize to obtain a basic compound. The base compounds were named E, F and G.

[0085]

[0086] To 100 parts by weight of each base compound was added 1 part by weight of 2 / g of specific surface area of cerium oxide and 0.8 parts by weight of a paste containing 80% by weight of 2,5-dimethyl-2,5-bis(tert-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com