A durable deodorant and antibacterial finishing process for ready-made garments

An antibacterial finishing and garment technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of bacterial growth, poor air permeability, low hygroscopicity, etc., and achieve the effect of small electrostatic effect, easy washing, and not easy to vacuum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a complete example of the implementation of the invention:

[0020] 1. Yarn-dyed fabric with specifications T / C65 / 35 80s / 2×80s / 2 118×78 57″ is selected for the fabric

[0021] 2. The process is:

[0022] (1) Pre-baking: Padding and finishing the fabric with a pH value of 6.5-7 on the cloth surface, then drying at 80-100°C for 0.5-1 hour, and then baking at 150-180°C for 6-7min; , the squeeze rate is 60%-80%;

[0023] (2) Baking after delay: Fabric padding and finishing liquid → bake to the specified moisture content → wrap plastic film on the outside to prevent moisture loss during transportation or storage → cut the garment → press at 175-185°C for 30-40s , make it flat or produce creases according to requirements → bake in a baking room at 130-140°C for 15-30min;

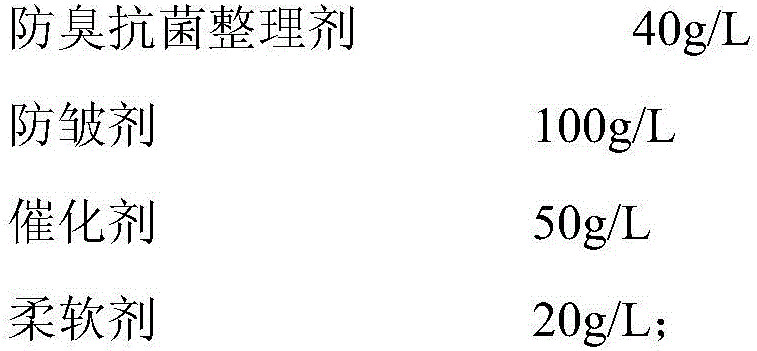

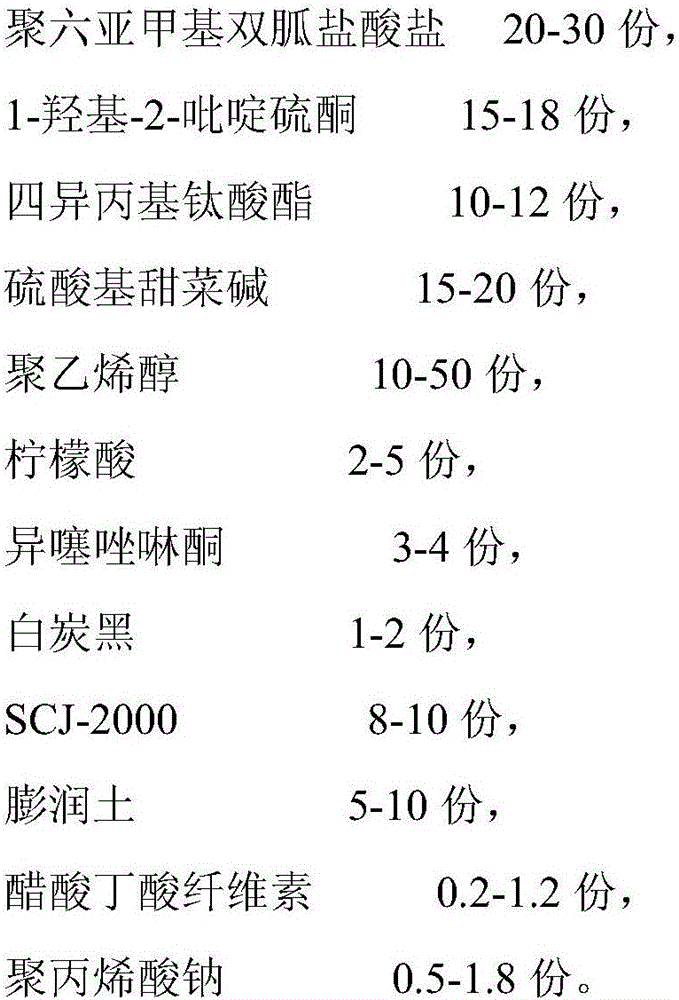

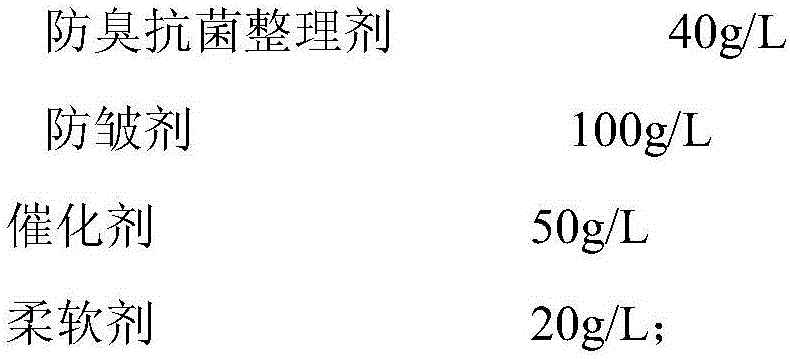

[0024] (3) Garment finishing: clothing impregnated finishing solution→centrifugal dehydration, recovering residual liquid→drum drying at 60-80°C until the moisture content is about 20%→i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com