An airgel-filled pineapple-based composite fiber and its preparation process

A composite fiber and preparation technology, which is applied in the field of textile fibers, can solve the problems that performance characteristics cannot be fully utilized, and achieve excellent breathable and sweat-absorbing effects, improved inferior performance, and no pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

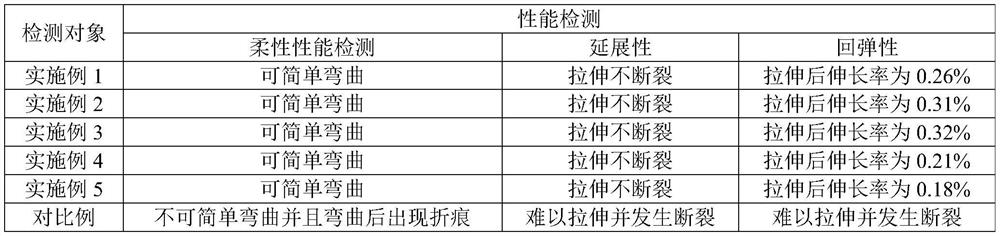

Examples

Embodiment 1

[0035] A kind of preparation technology of airgel filling pineapple base composite fiber, described preparation technology comprises following preparation steps:

[0036] 1) Prepare pineapple fiber superfine powder suspension: put pineapple fiber powder in an ultrafine pulverizer and pulverize to 300 mesh, and pulverize to obtain pineapple fiber superfine powder, and pineapple fiber superfine powder and concentration are 10wt% casein solution Mix with a mass ratio of 5:3, and ultrasonically vibrate until a uniformly dispersed pineapple superfine powder suspension is formed;

[0037] 2) Preparation of airgel precursor: dissolve resorcinol in saturated calcium hydroxide aqueous solution or saturated magnesium hydroxide aqueous solution, stir while adding dropwise 37wt% concentration of formaldehyde solution until the solution is colorless and transparent, after standing Under the conditions of 25°C and 45°C in constant temperature water baths for 18 hours, the airgel precursor w...

Embodiment 2

[0041] A kind of preparation technology of airgel filling pineapple base composite fiber, described preparation technology comprises following preparation steps:

[0042]1) Prepare the pineapple fiber superfine powder suspension: put the pineapple fiber powder in an ultrafine pulverizer and pulverize it to 600 mesh, pulverize to obtain the pineapple fiber superfine powder, and mix the pineapple fiber superfine powder with a concentration of 10wt% casein solution Mix with a mass ratio of 5:4, and ultrasonically vibrate until a uniformly dispersed pineapple superfine powder suspension is formed;

[0043] 2) Preparation of airgel precursor: dissolve resorcinol in saturated calcium hydroxide aqueous solution or saturated magnesium hydroxide aqueous solution, stir while adding dropwise 37wt% concentration of formaldehyde solution until the solution is colorless and transparent, after standing The airgel precursor was obtained in constant temperature water baths at 35°C and 55°C for...

Embodiment 3

[0047] A kind of preparation technology of airgel filling pineapple base composite fiber, described preparation technology comprises following preparation steps:

[0048] 1) Prepare pineapple fiber superfine powder suspension: put pineapple fiber powder in an ultrafine pulverizer and pulverize to 450 mesh, pulverize to obtain pineapple fiber superfine powder, and pineapple fiber superfine powder and concentration are 10wt% casein solution Mix at a mass ratio of 5:3.5, and ultrasonically vibrate until a uniformly dispersed pineapple superfine powder suspension is formed;

[0049] 2) Preparation of airgel precursor: dissolve resorcinol in saturated calcium hydroxide aqueous solution or saturated magnesium hydroxide aqueous solution, stir while adding dropwise 37wt% concentration of formaldehyde solution until the solution is colorless and transparent, after standing The airgel precursor was obtained in constant temperature water baths at 30°C and 50°C for 24 hours; the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com