Self-relieving hydraulic cylinder and steel bar bending machine

A hydraulic cylinder and self-relieving technology, which is applied in the field of hydraulic cylinders, can solve problems that affect the service life of hydraulic cylinders, hydraulic cylinders do not have parts that prevent cylinder expansion, damage, etc., and achieve the effect of ensuring service life and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

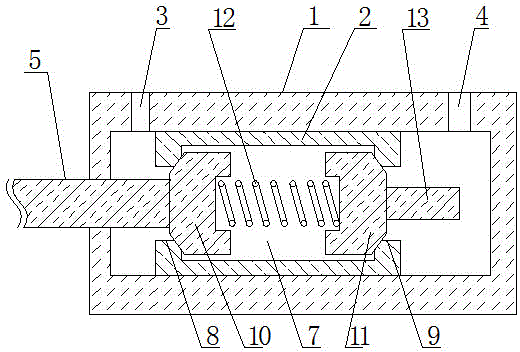

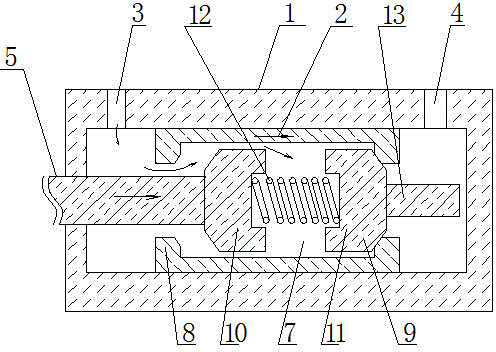

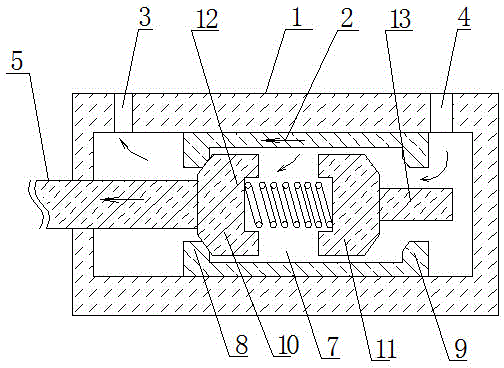

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] like figure 1 , 2 As shown in , 3, the self-releasing hydraulic cylinder includes a cylinder tube 1 and a piston 2, the cylinder tube has a first inlet and outlet 3 and a second inlet and outlet 4 for hydraulic fluid, and the piston 2 is installed in the cylinder tube 1 Inside, the piston 2 is connected with a connecting rod 5;

[0021] It is characterized in that: the inside of the piston has a hollow structure 7, the hollow structure is connected at both ends, the left end of the hollow structure is a left inner protruding edge 8, and the right end of the hollow structure has a right inner The protruding edge 9 has two conical blocks in the hollow structure, which are the left conical block 10 and the right conical block 11 respectively, and there is a spring 12 between the left conical block 10 and the right conical block 11. the groove and connect the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com