Measurement method of order production cycle and output

A technology of production cycle and measurement method, applied in forecasting, data processing applications, resources, etc., can solve problems such as poor production planning, failure to consider order placement, product interspersed production process, high prices, etc., and achieve the effect of avoiding output loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

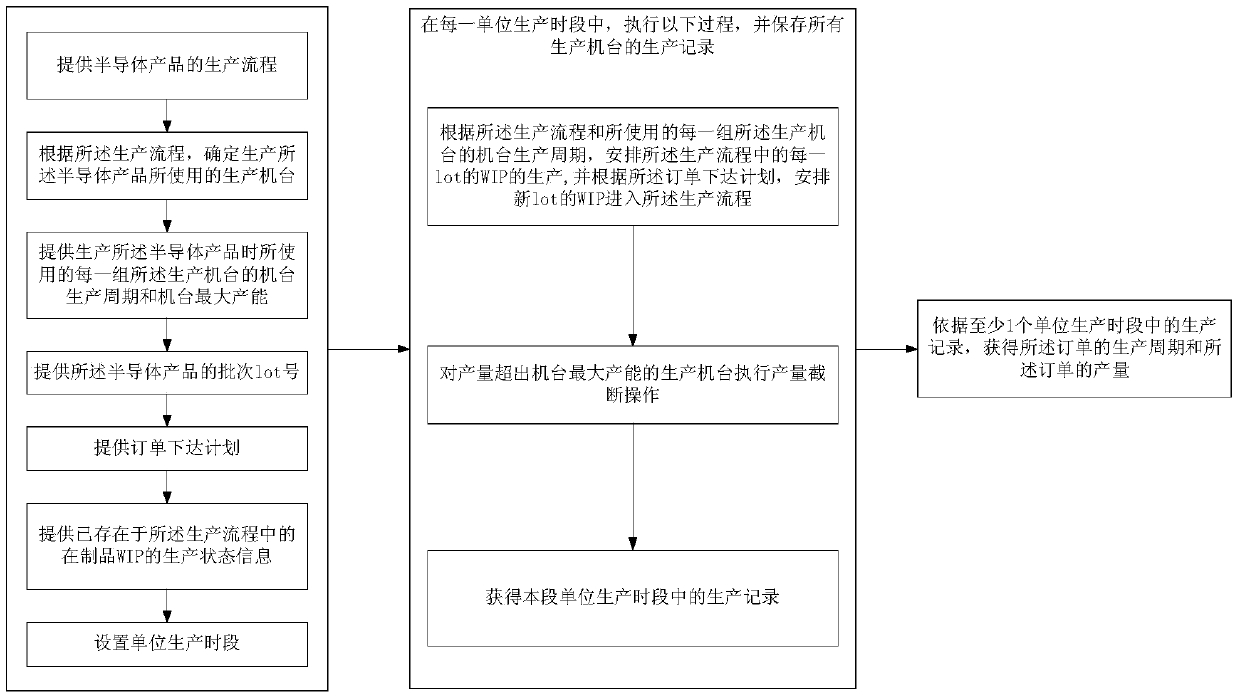

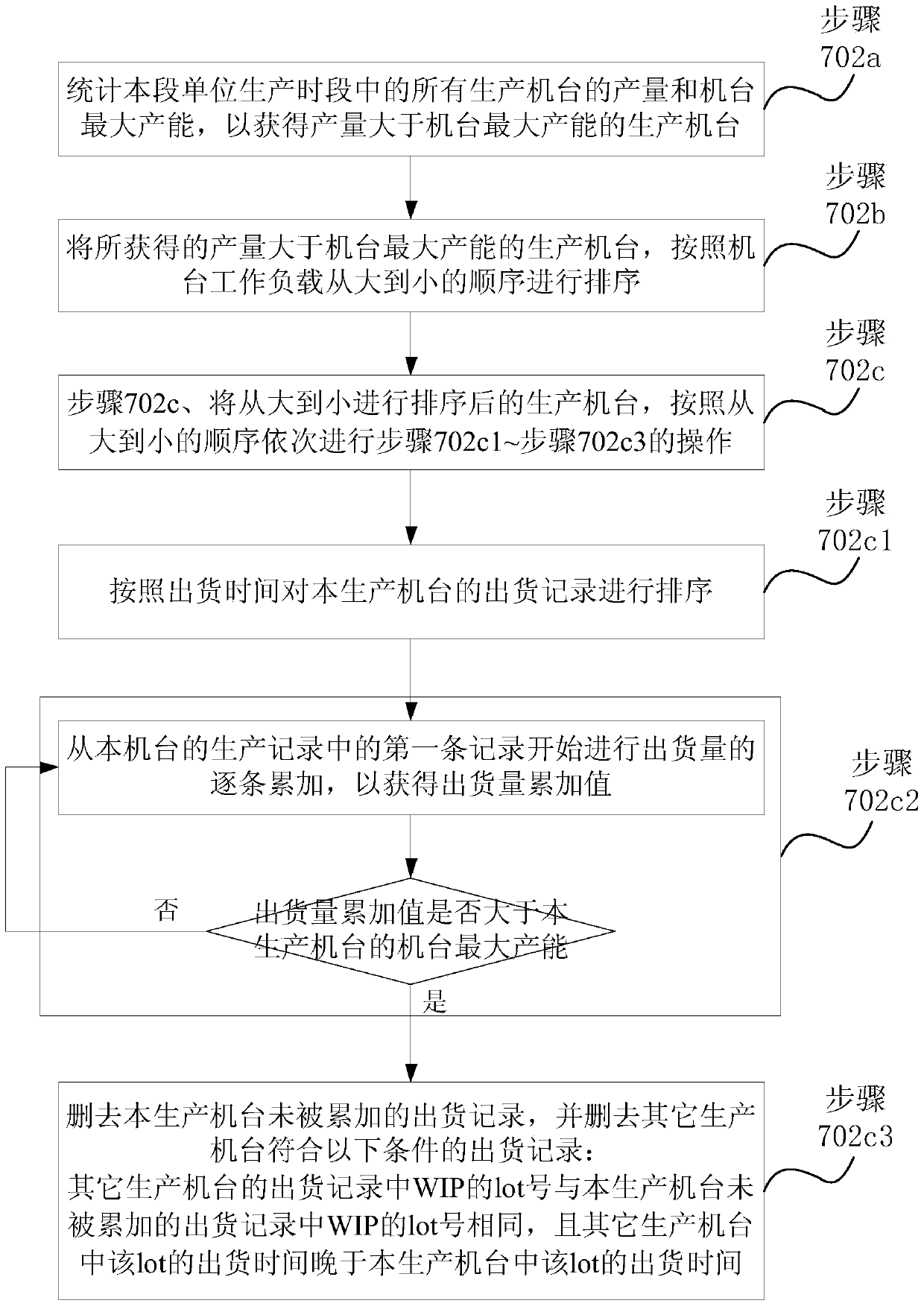

[0035] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0036] Such as figure 1 Shown, the measurement method embodiment of order production cycle and output of the present invention, comprises:

[0037] Provide the production process of semiconductor products;

[0038] According to the production process, determine the production machine used to produce the semiconductor product;

[0039] Provide the machine production cycle and the maximum production capacity of each set of production machines used in the production of the semiconductor products;

[0040] Provide the lot (batch) number of the semiconductor product in question;

[0041] Provide order release plan;

[0042] Provide information on the production status of WIP that already exists in the production process;

[0043] Set the unit produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com