Method for increasing stator core slot area, stator core, stator and motor

A technology of stator iron core and stator slot, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of heavy motor, high motor material cost, and high motor transportation cost, so as to reduce the overall cost, The effect of improving motor efficiency and increasing slot area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

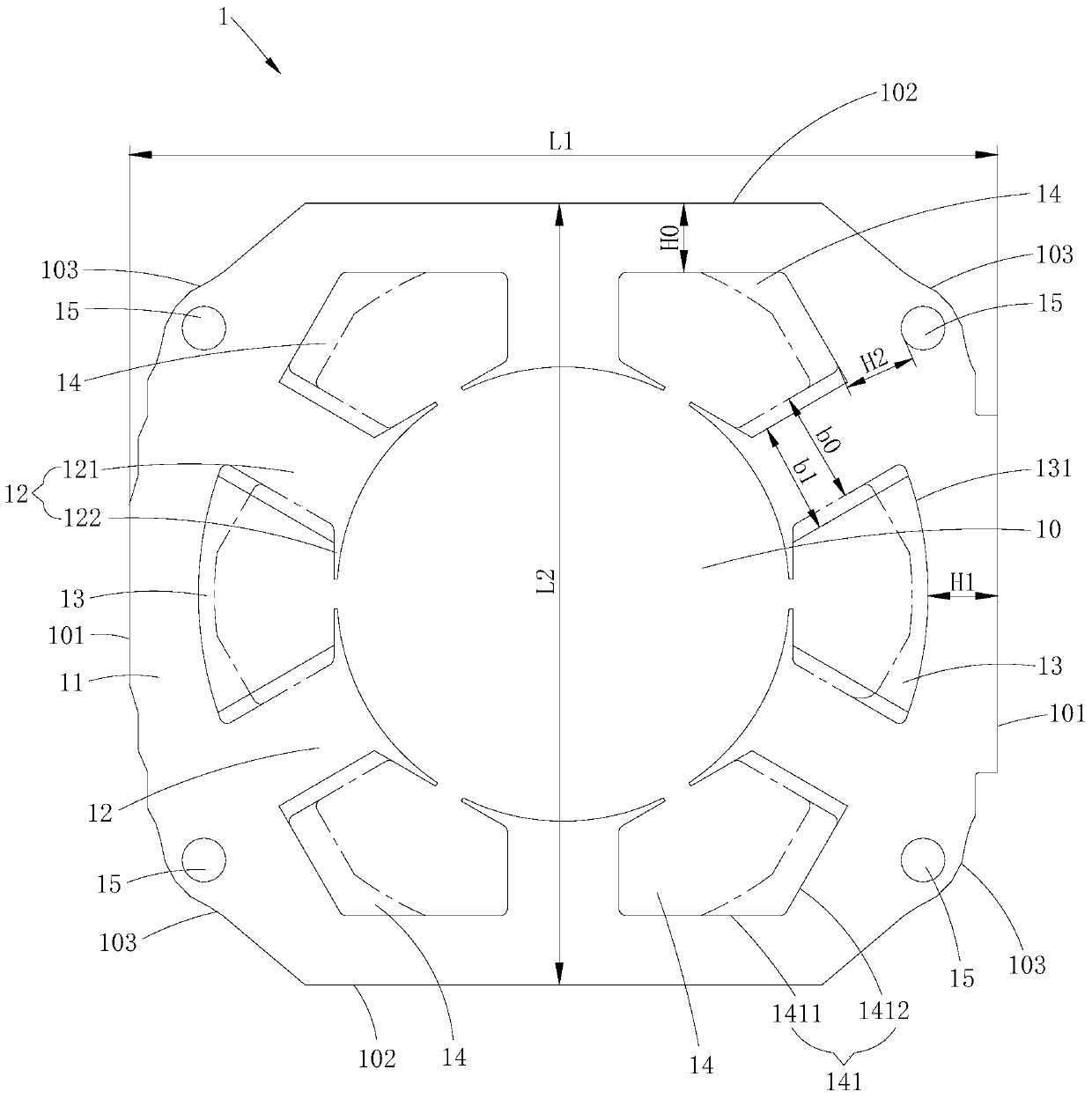

[0023] Such as figure 1 As shown, the method for increasing the slot area of the stator core provided by Embodiment 1 of the present invention is suitable for the outer contour including two opposite first straight outer edges 101, two opposite second straight outer edges 102 and four opposite straight outer edges. A stator core 1 with two corner outer edges 103, wherein, two first straight outer edges 101 are opposite and arranged in parallel, and two second straight outer edges 102 are opposite and arranged in parallel. Specifically, the stator core 1 includes a circumferentially closed stator yoke 11 and several stator teeth 12 protruding inside the stator yoke 11 at intervals along the circumferential direction, and any two adjacent stator teeth 12 are enclosed to form a stator slot. The stator tooth 12 includes a tooth neck 121 connected to the stator yoke 11 and a tooth shoe 122 protruding from the end of the tooth neck 121. Each tooth shoe 122 encloses and forms a ro...

Embodiment 2

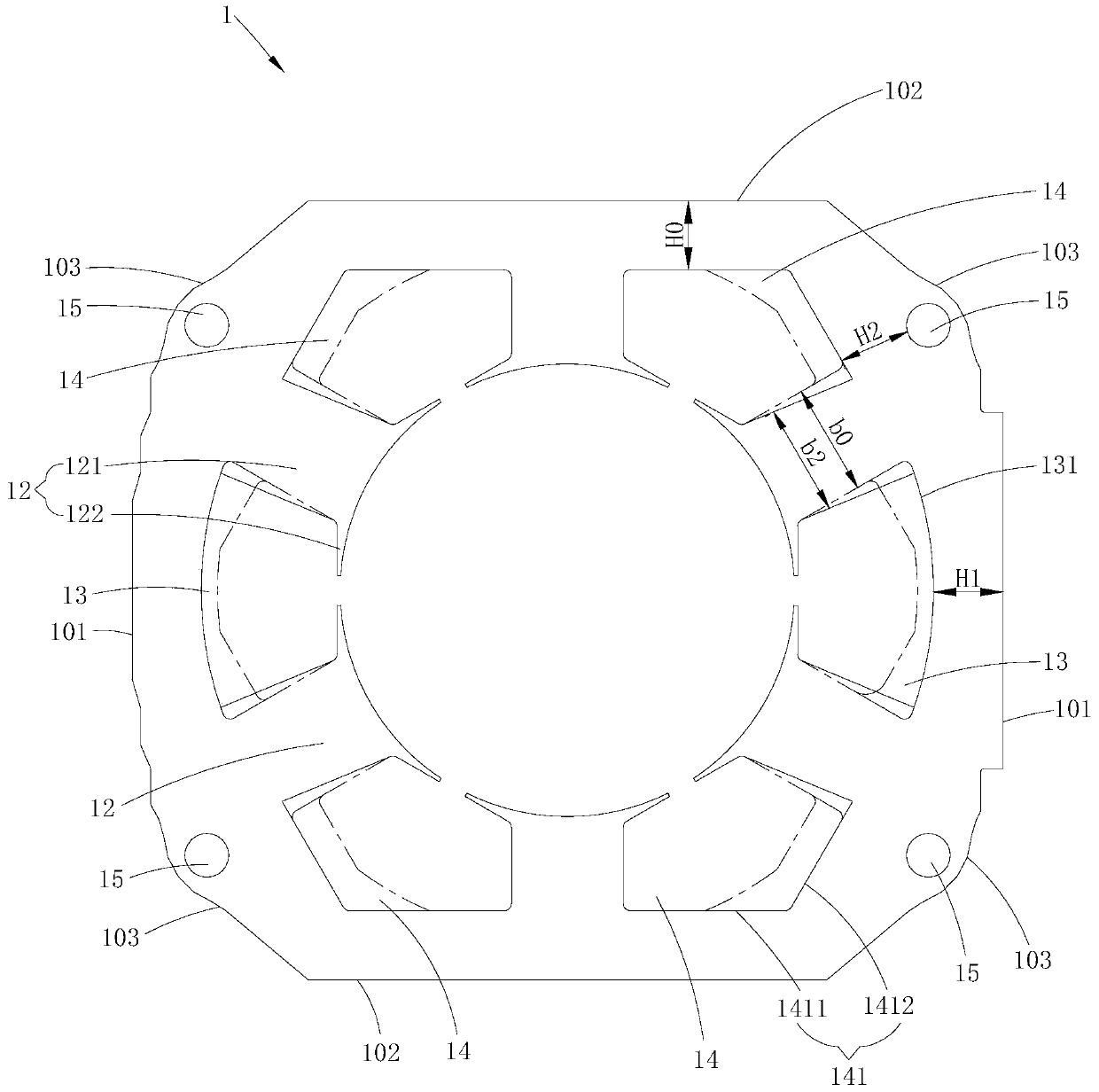

[0038] Such as figure 2 As shown, the same as the first embodiment, the method for increasing the area of the stator core slots provided by this embodiment is also to increase the recessed depth of the stator slots recessed toward the outer edge 101 of the first straight side to form The first stator slot 13 and the bottom slot walls of the stator slots that are recessed towards the corner outer edge 103 and the second straight outer edge 102 at the same time face in a way that the distance H0 between the second straight outer edge 102 remains unchanged. The corner outer edge 103 is concavely extended to form the second stator slot 14, and also the distance H1 from the bottom slot wall 131 of the first stator slot 13 to the first straight outer edge 101, the bottom slot wall of the second stator slot 14 The distance H2 from 141 to the positioning hole 15 is set to be greater than or equal to the distance H0 from the bottom wall 141 of the second stator slot 14 to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com