Heel backer shaper

A shoe heel and shaping machine technology, which is applied in the field of shoemaking, can solve the problems of not being able to achieve smoothness and smoothness, and cannot ensure good contact with the heel, and achieve the effects of improved temperature control accuracy, smooth plane, and clear edge lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

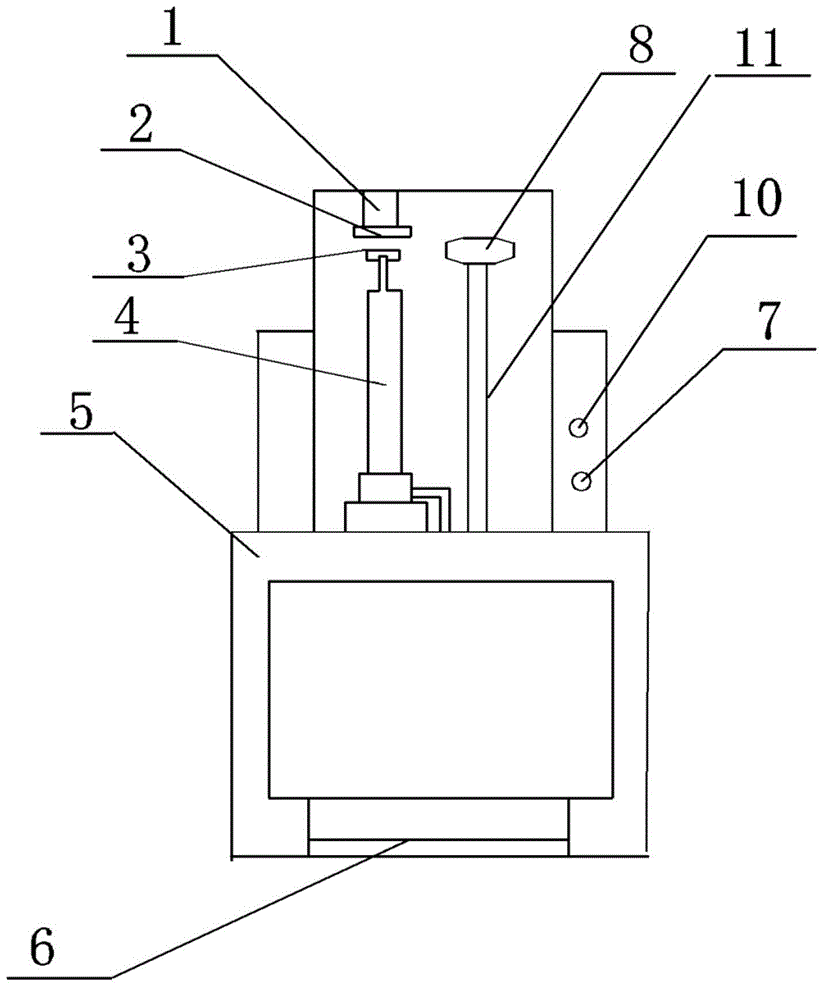

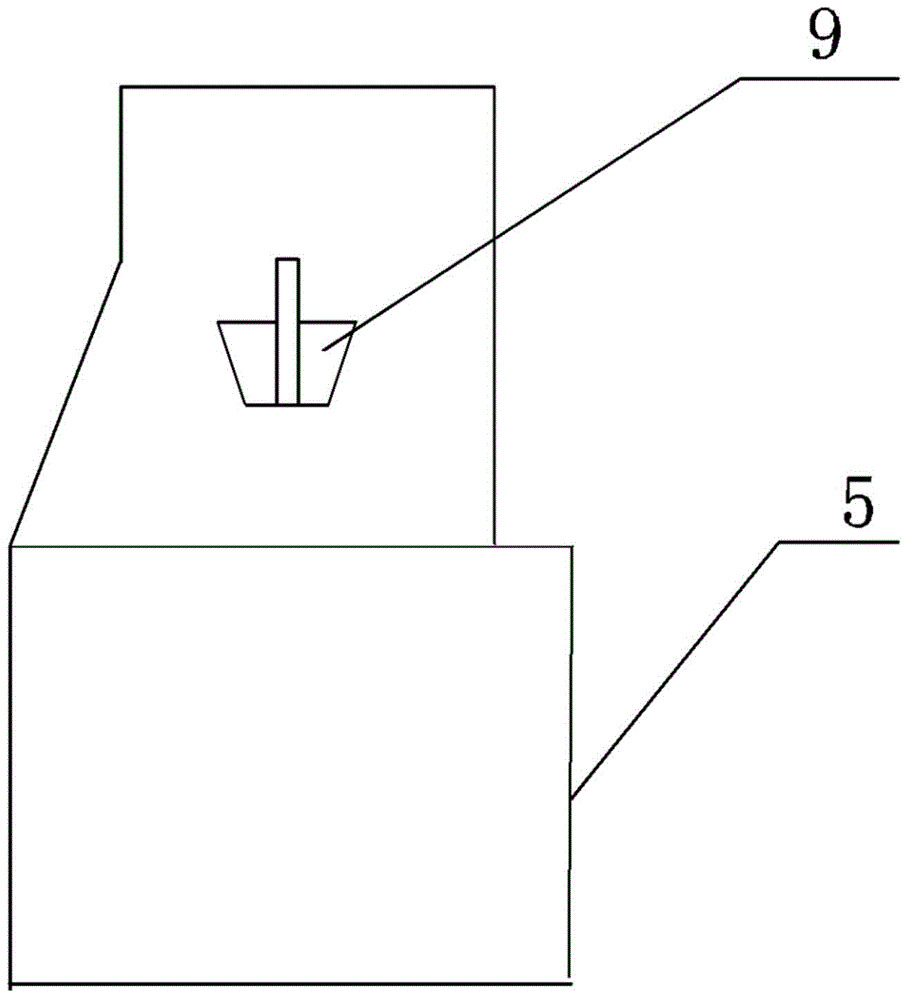

[0013] A shoe heel seat shaping machine, comprising a chassis 5, a last pressing and ironing seat 1, a shoe last turning mechanism, a shaping wheel 8, an automatic selection switch 9, and a foot pedal 6. The lower half of the chassis 5 is sealed to seal the space An air pump is built in, and the pedal 6 is arranged at the bottom of the cabinet 5 to control the air pump in the cabinet 5. One side of the upper half of the cabinet 5 is not closed, and the shoe last turning mechanism is arranged on the upper half of the cabinet. The shoe last turning mechanism is composed of Composed of cylinder 4 and turntable 3, turntable 3 is set on the top of cylinder 4, last ironing seat 1 is set on the inner wall of the top of cabinet 5, facing the position of turntable 3, said last ironing seat 1 is equipped with electric heating Plate 2, the electric heating plate 2 is connected to the thyristor voltage regulator 10 arranged on the side wall of the case.

[0014] The shaping wheel 8 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com