Direct-current double-layer pressure feedback pressure cooker and control method thereof

A pressure cooker and pressure technology, which is applied in the field of pressure cooker, can solve the problems that the temperature of the inner tank cannot be further increased, the energy consumption is large, and the pressure value is limited, so as to achieve the effects of improving production quality, increasing production temperature, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

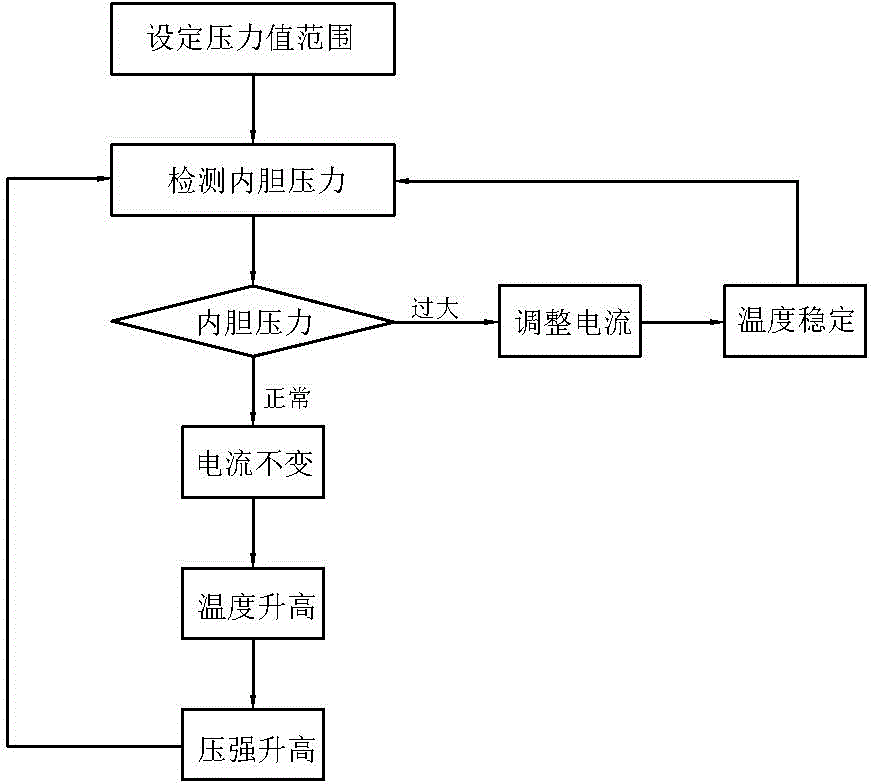

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

[0017] The DC double-layer pressure feedback pressure cooker of this embodiment includes an outer container, an inner container, and a cover body, and the inner container may be one or two, and the bottom of the outer container is provided with a heater for heating the inner container and The control circuit, the heater is powered by 24v or 48v direct current, the cover is provided with an inner tank seal ring and an outer tank seal ring, and the inner tank seal ring is sealed and connected between the cover body and the inner tank, so The sealing ring of the outer tank is sealed and connected between the cover and the outer tank. After the cover is tightly closed, two sealed spaces are formed, one is inside the inner tank, and the other is between the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com