A stirring sewage treatment device

A sewage treatment device and agitation technology, which is applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of difficult cleaning, single function, environmental pollution, etc., to ensure stability and prevent the rotating shaft from passing long, noise-avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

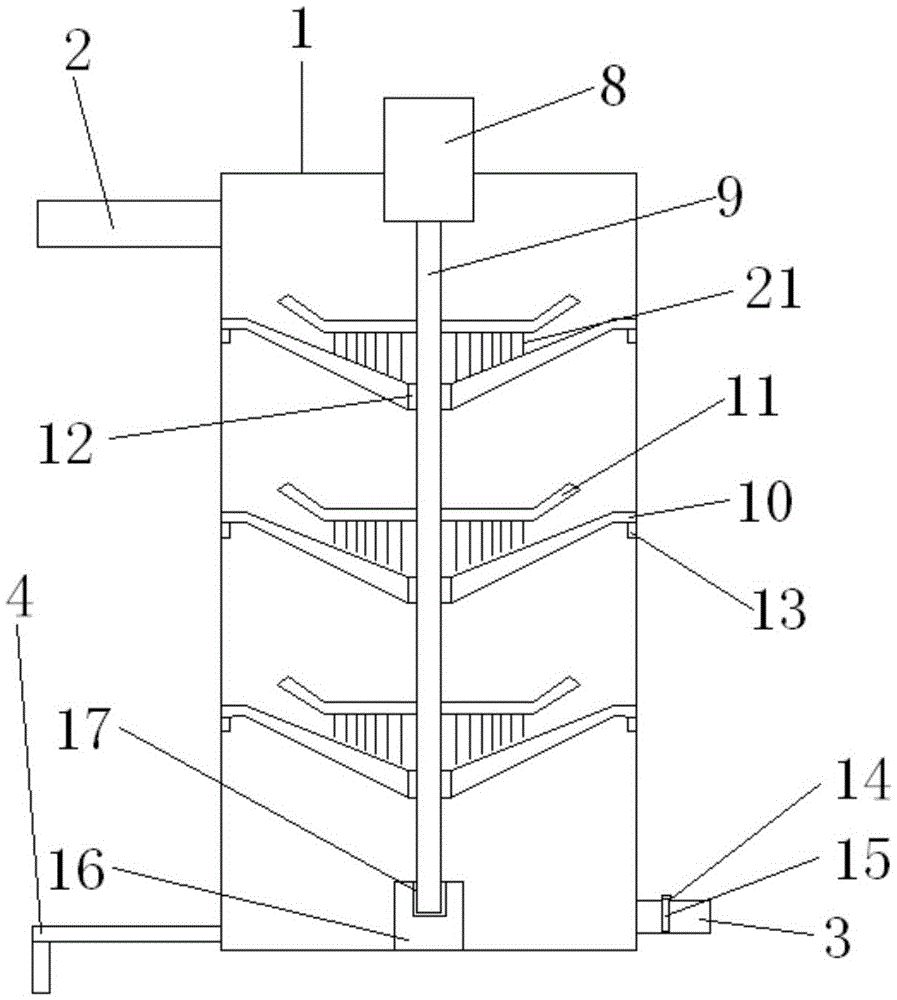

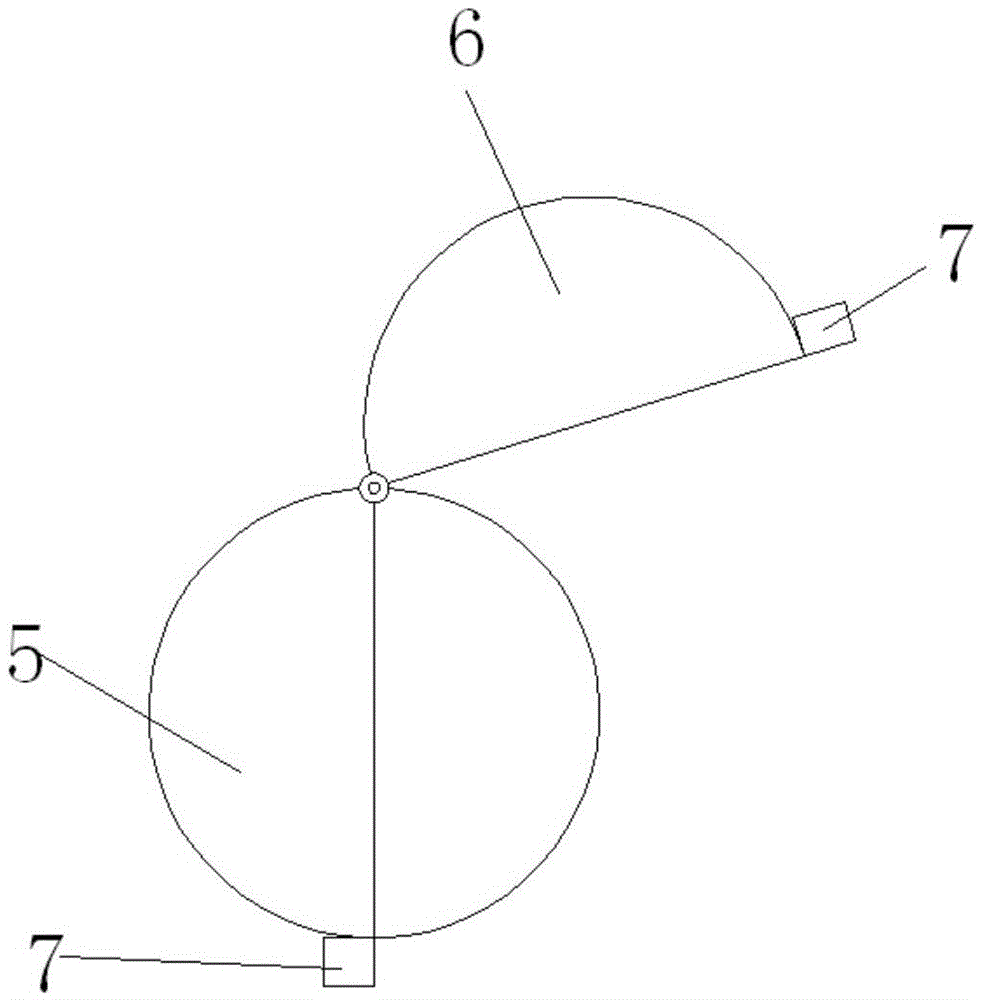

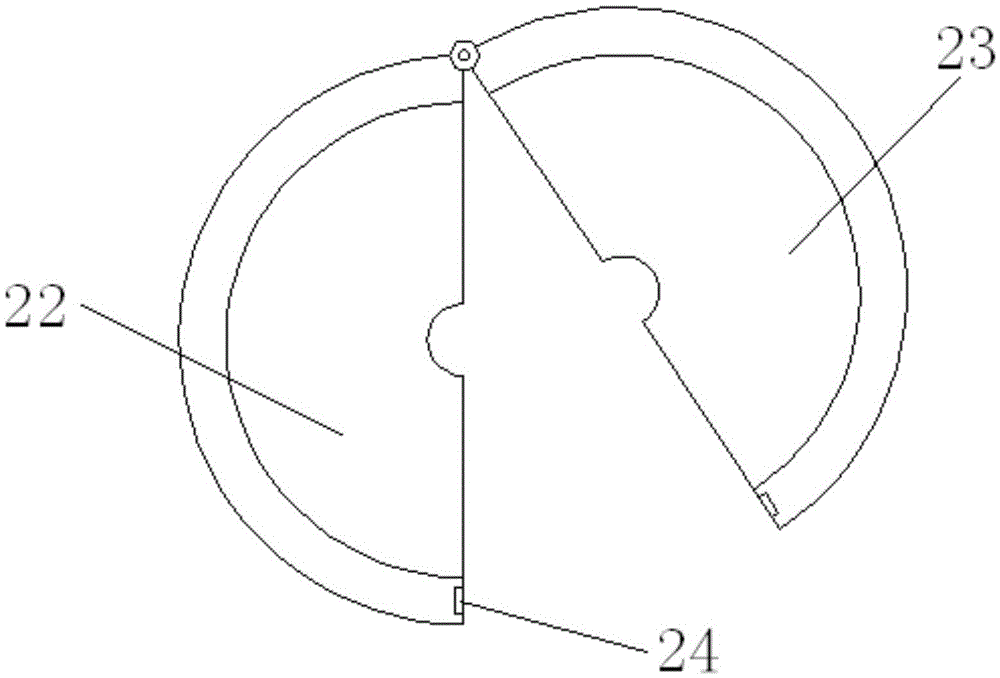

[0029] Such as figure 1 , figure 2 and image 3 As shown, the stirring sewage treatment device includes a housing 1, the housing 1 is a barrel-shaped structure, the top of the housing 1 is provided with a sewage inlet pipe 2, the bottom of the housing 1 is provided with a water outlet pipe 3, and the bottom of the housing 1 is provided with a water outlet pipe 3. A water quality test tube 4 is also provided, and a plurality of filter screens 10 are equidistantly arranged in the housing 1. The filter screen 10 is an inverted cone structure, and the housing 1 is divided into a left housing 5 and a right housing 6, both of which are hinged. , the connection between the two is provided with a rubber layer, and a connection and fixing device 7 is also provided between the left ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com