Intelligent water removal room for OLED (organic light emitting diode) glass substrates

A glass substrate and intelligent technology, which is applied in the field of OLED display, can solve the problems that the temperature of the baking device and cooling device cannot be measured, the quality of the glass substrate is affected, and the degree of automation is not high, so as to improve the degree of intelligent automation, speed up the production cycle, and improve production. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

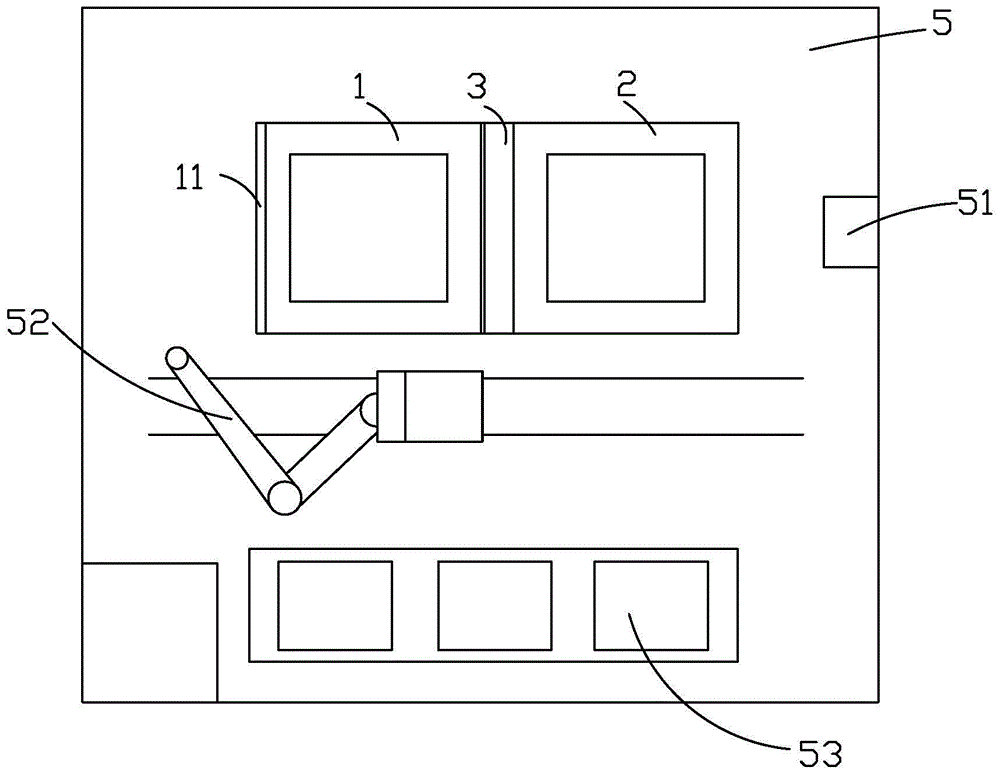

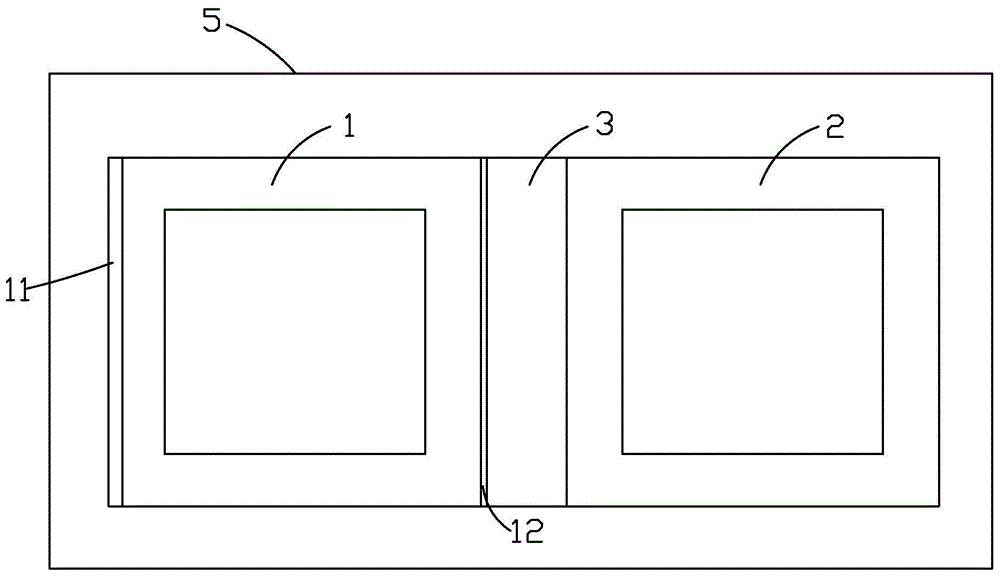

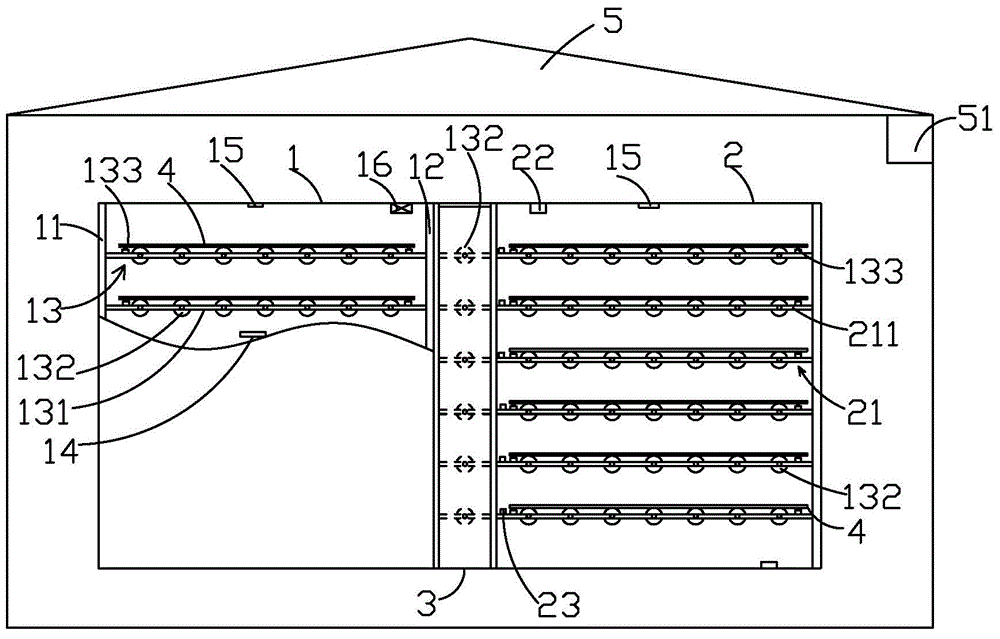

[0018] Such as Figure 1 to Figure 4 As shown, the technical solution of the present invention is an intelligent OLED glass substrate dewatering room: comprising a clean room 5, a baking furnace 1 and a cooling furnace 2 are arranged in the clean room 5, the surroundings of the baking furnace 1 are closed, and the front end is provided with an inlet The charging furnace door 11, the rear end of the baking furnace 1 communicates with the cooling furnace 2 through the transition channel 3, a movable isolation furnace door 12 is arranged between the baking furnace 1 and the transition channel 2, and at least one layer of baking furnace is arranged in the baking furnace 1. Unit 13, the baking unit 13 includes a baking platform 131 fixed on the side wall of the baking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com