Treatment method for roof disasters in large dipped coal seams

A coal seam roof and large inclination angle technology, which is applied in earth square drilling, ground mining, underground mining, etc., can solve problems such as mine pressure display distance, hidden safety hazards, and storms, so as to reduce risks, reduce risk factors, and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

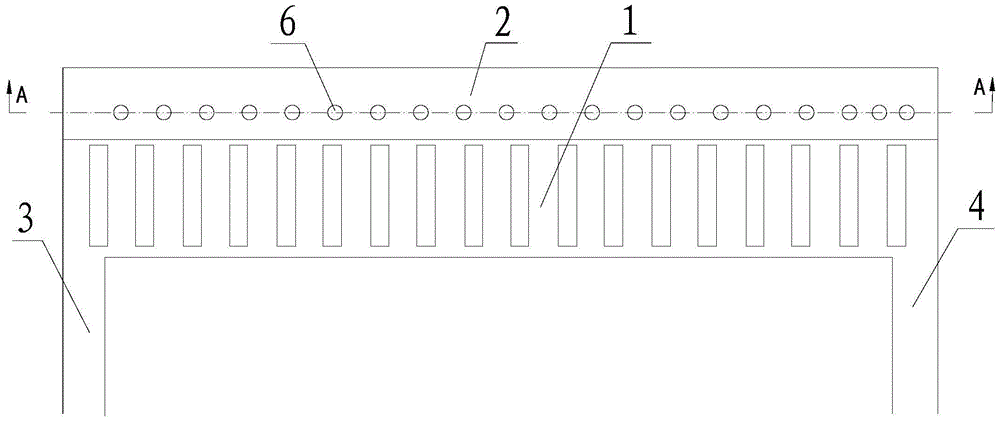

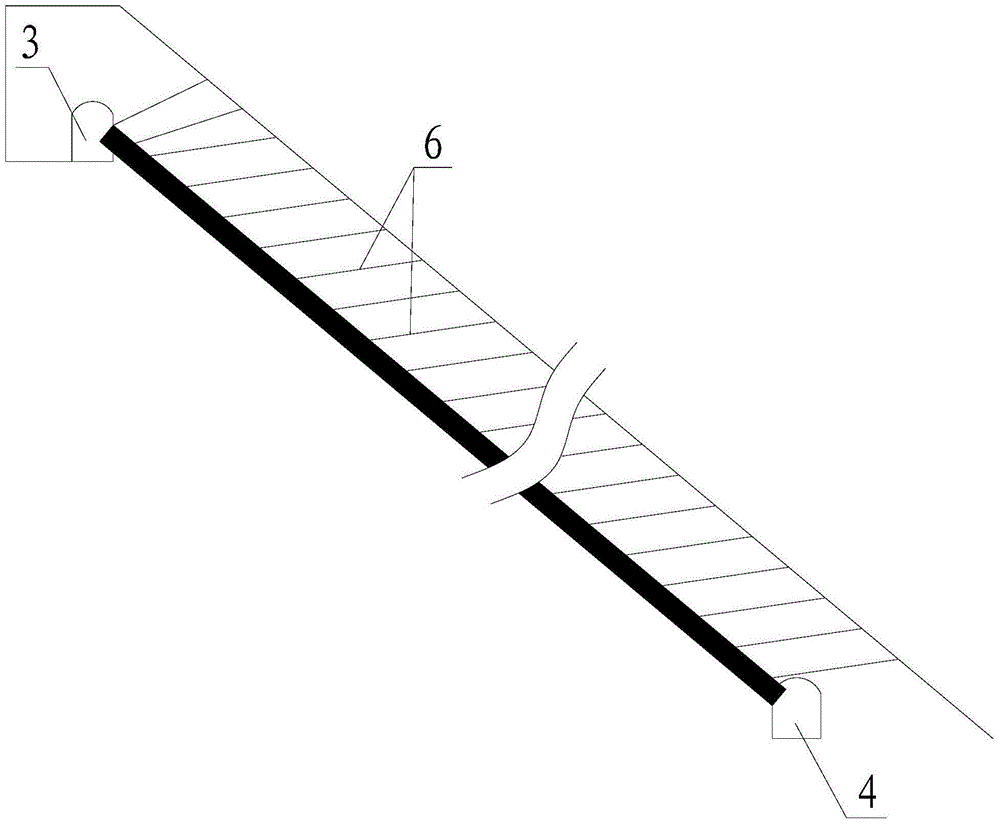

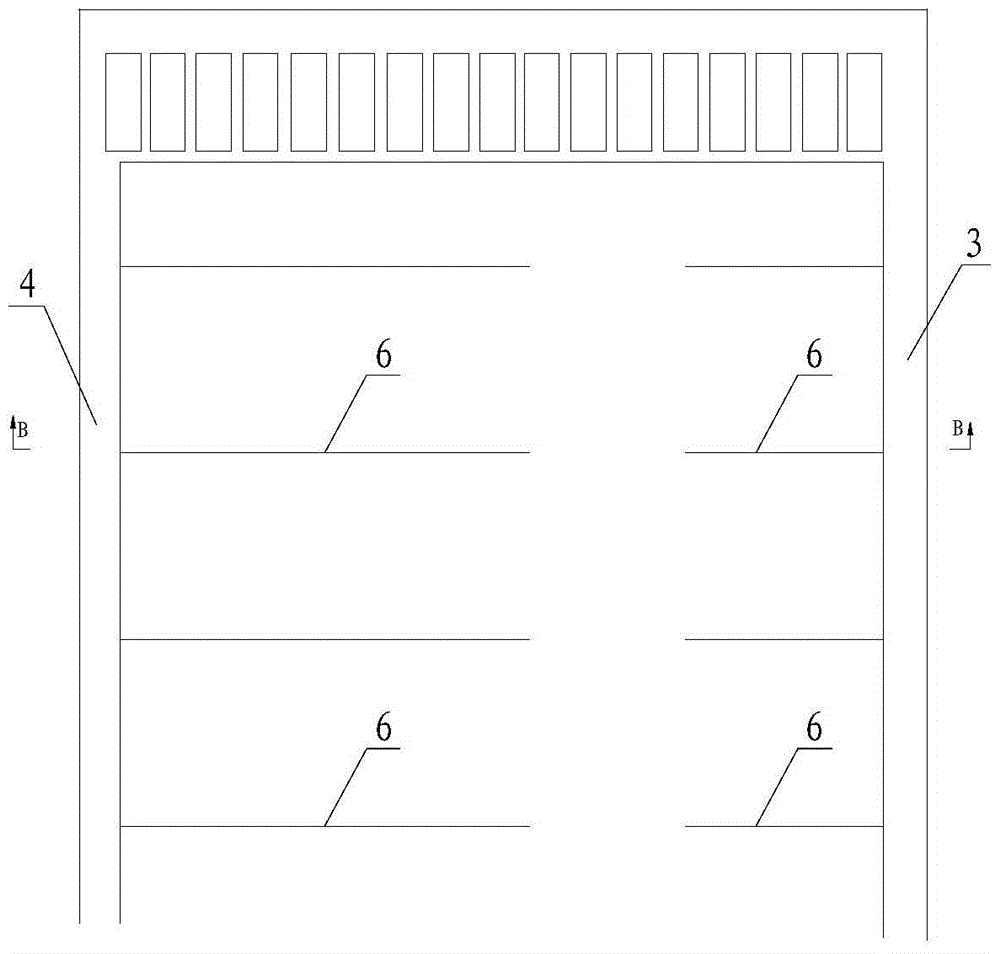

[0043] Such as Figure 1 to Figure 7 Shown is a roof disaster control method for high-inclination coal seams provided by the present invention, which can effectively ensure the safety of mechanized mining under the condition of hard roofs in inclined coal seams, and greatly reduce the risk of coal mining under similar conditions. The governance method includes the following steps,

[0044] a. Shallow-hole slot blasting is performed on the roof 2 of the coal seam cutout 1 in the working face to weaken the roof 2 at the cutout;

[0045] b. Carry out advanced deep hole weakening blasting on the coal seam roof of the working face according to a certain step through the air return lane 3 and the transport lane 4 respectively, so as to weaken the roof 2 of the working face in advance, and follow up for mining;

[0046] c Use the upper corner of the return air lane 3 of the working face to blast the roof 2, and fall the roof 2 of the upper corner tail lane of the goaf of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com