Steam generator and steam generating method

A steam generator and steam technology, applied in the field of kitchen equipment, can solve the problems of low efficiency, complex structure, low heat utilization rate, etc., achieve high heat utilization rate, ensure heating effect, and improve the effect of heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

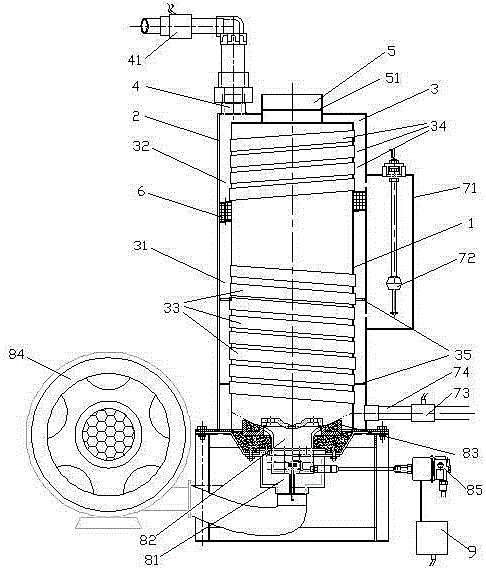

[0035] The steam generator provided in this embodiment includes an inner tank 1, an outer tank 2, an interlayer 3, a steam outlet 4 and a smoke outlet 5, and the smoke outlet 5 is arranged above the inner tank 1 and connected to the atmosphere; An interlayer 3 is provided between the inner container 1 and the outer container 2, and a steam outlet 4 is provided above the interlayer 3; the middle or upper middle part of the interlayer 3 is provided with a water vapor separator 6, and the interlayer 3 is divided into the lower part by the water vapor separator 6. The water storage chamber 31 and the steam heating chamber 32 on it;

[0036] A water heating pipe 33 runs through the inner tank 1, and the water heating pipe 33 communicates with the water storage chamber 31. The water heating pipe 33 is arranged obliquely, and the included angle between the axial direction and the horizontal is 6° ;

[0037] A steam heating tube 34 runs through the inner tank 1, and the steam heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com