A test device that can automatically adjust the lip opening angle of the supercombustion inlet

A technology of automatic adjustment and test device, applied in aerodynamic test, measurement device, test of machine/structural parts, etc., can solve the problems of real-time measurement of lip angle, energy waste, inaccurate test results, etc., to improve control and acquisition accuracy, reducing interference effects, and improving the effect of response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

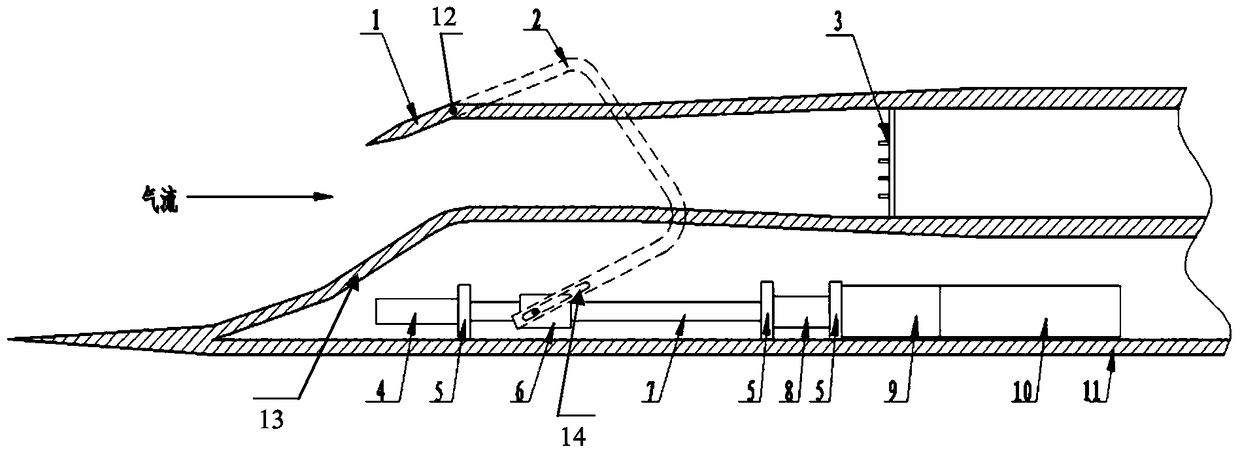

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] see figure 1 , the present invention provides a test device that can automatically adjust the opening angle of the lip of the supercombustion inlet, including: a fixed part 13 and a movable part 1 that define the lip of the inlet, and the movable part The end is pivotally connected to the wall of the air inlet through a pivot 12; the lead screw 7; the movable nut 6, which is threadedly matched with the lead screw, is sleeved on the lead screw in a manner that can move along the lead screw; Rod 2, one end of which is connected to the movable part, and the other end is connected to the movable nut; a rotary drive mechanism, which is connected to one end of the lead screw, drives the lead screw to rotate so that the movable part D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com