Variable Mach number motion control device for hypersonic-speed variable Mach number wind tunnel nozzle

A motion control device and hypersonic technology, applied in the direction of measuring devices, aerodynamic tests, machine/structural component testing, etc., can solve problems such as complex methods, achieve the effect of balancing the driving force and avoiding possible damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

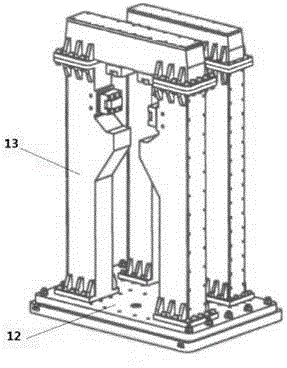

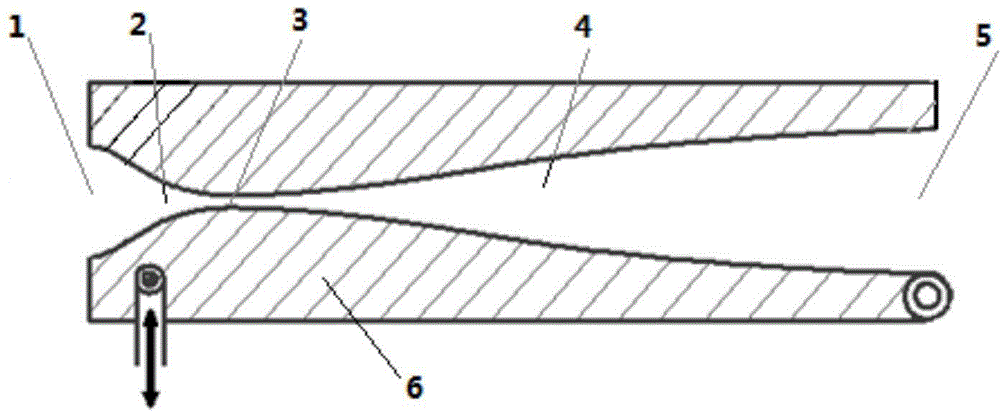

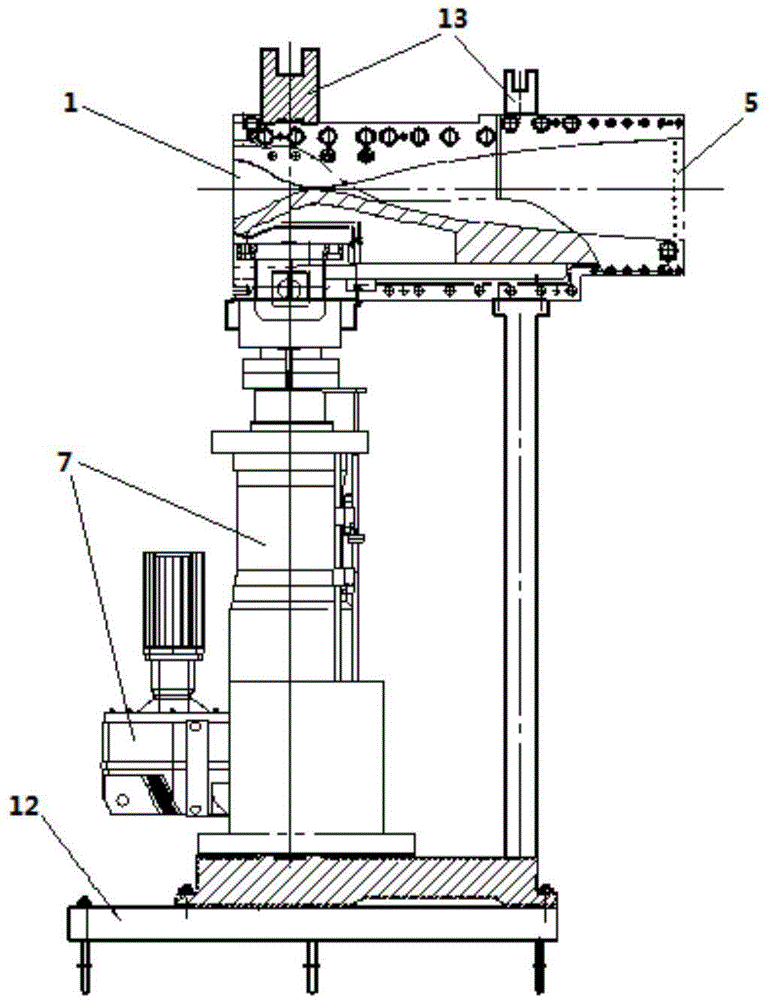

[0012] Such as Figure 1-3 As shown, the variable Mach number motion control device of this hypersonic variable Mach number wind tunnel nozzle, the hypersonic wind tunnel variable Mach number nozzle is formed by the space surrounded by the fixed curved plate, the rotating curved plate 6 and the two side plates. The air flow channel of the pipe includes inlet 1, contraction section 2, throat 3, expansion section 4, and outlet 5 from front to back. The inlet is connected to the heater, and the outlet is connected to the wind tunnel experiment cabin. The rear end of the rotating curved plate is fixed to the outlet of the nozzle At , the variable Mach number of the hypersonic wind tunnel nozzle is realized by rotating the curved plate around the outlet axis. The variable Mach number motion control device of the hypersonic variable Mach number wind tunnel nozzle includes a drive system located in the contraction section, a position Monitoring system and support system; the drive sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com