Method and system for preventing reel sinking deformation of galvanized steel reels

A technology of galvanized steel and steel coil, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve problems such as unusability, easy collapse of coil deformation, economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0029] In an embodiment of the present invention, a method for improving collapse deformation of a galvanized steel coil is provided. The main purpose of this method is to improve the collapse and deformation of galvanized steel coils during stacking and transportation.

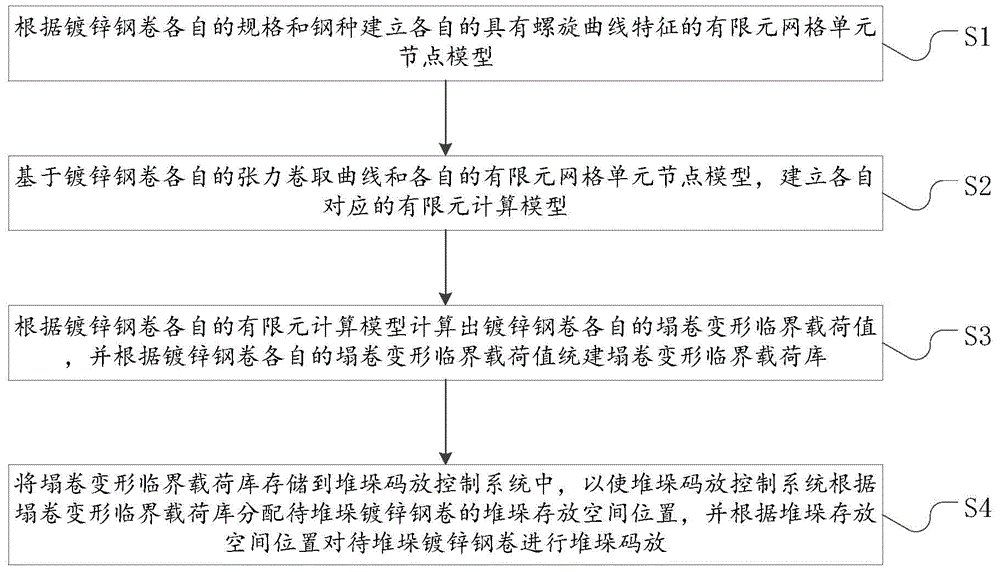

[0030] See below figure 1 , is the implementation flowchart of the method of the embodiment of the present invention, including:

[0031] S1, according to the specifications and steel grades of galvanized steel coils, establish their respective finite element mesh unit node models with spiral curve characteristics.

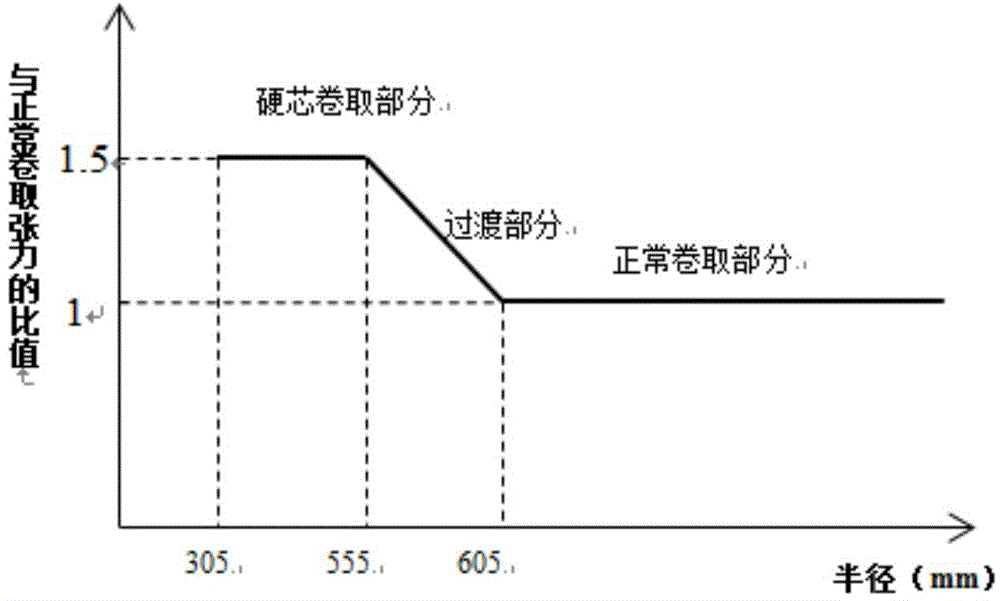

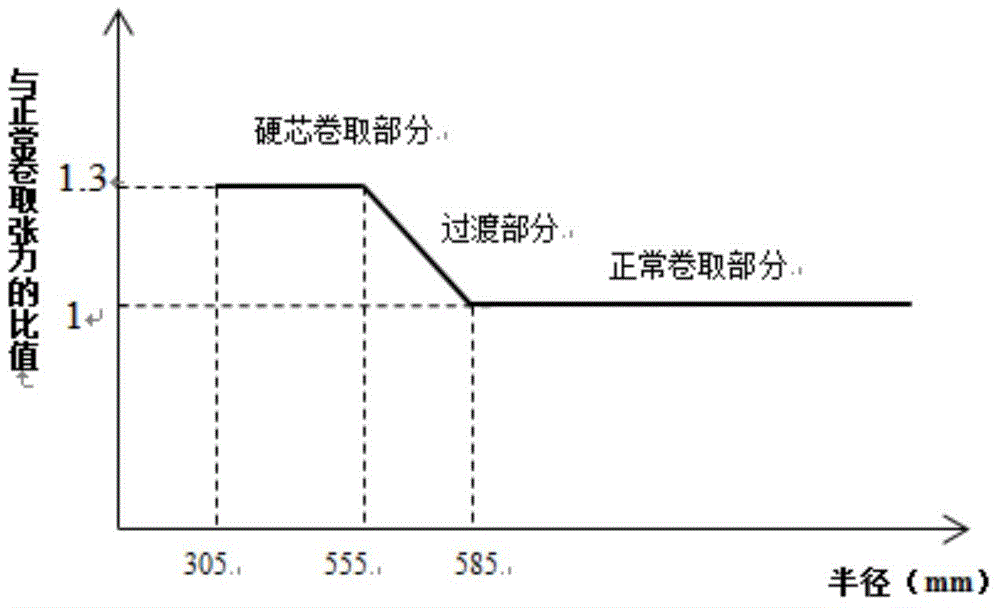

[0032] Specifically, the coiling tension database can be established firstly according to the steel ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com