Design method for intelligent electric appliance general structural member of building block combination type

A technology of general structure and intelligent electrical appliances, applied in the field of electronics, can solve the problems such as the inability to meet the design requirements of image consistency and common parts, increase the input cost and management difficulty, and heavy design tasks, so as to shorten the development cycle and simplify the process assembly. Process, the effect of reducing the processing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0075] The method for designing the general structural parts of building block combined smart electrical appliances adopted by the present invention comprises the following steps:

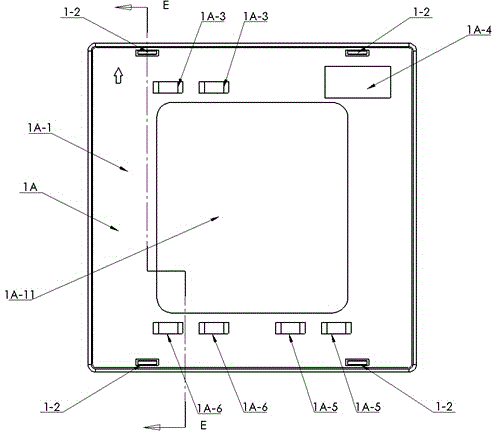

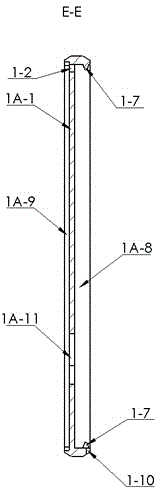

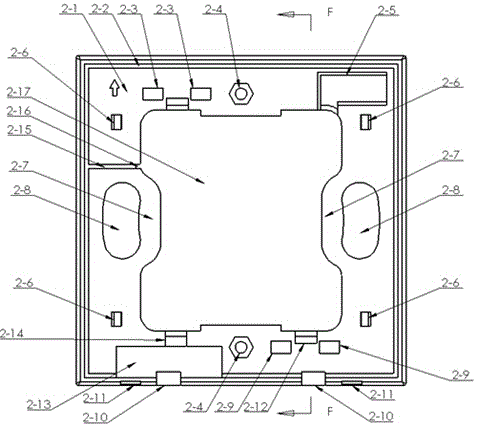

[0076] The first step is the planning of general structural parts: plan the general structural parts according to the components of electrical switches, electrical sockets or scene controllers, analyze the general functional modules of each series of products, and make the outer frame 1A of the first panel and the outer frame of the second panel Frame 1B, upper liner 2, metal liner 3, copper terminal 4, module lower case 5 and button part 6 are used as general structural parts of electrical switch, electrical socket and scene controller;

[0077] The second step is the design of general structural parts: design general structural parts according to the requirements of the overall structure of each independent product on product functions, the degree of correlation, standardization and versatility of...

specific Embodiment approach 2

[0083] Such as Figure 11 As shown, a switch glass panel 7 is pressed and bonded in front of the first panel outer frame 1A, and a nut 23 is installed in the upper lining nut mounting hole 2-4 of the upper lining 2, and the metal Install the lower module shell 5 behind the lining plate 3, and the lower module shell 5 is screwed with the nut 23 installed in the nut mounting hole 2-4 of the upper lining plate through the screw 24, and at the same time the lower module shell 5, the metal lining plate 3 and the upper lining plate are screwed 2 fixed, install the intelligent module circuit board 10 and one concealed intelligent switch key board 8 and copper terminal 4 in the module lower shell 5, the button part 6 is installed in the middle hole of the one switch glass panel 7, the intelligent module circuit board 10 and one concealed smart switch key board 8 are connected through two pins 9, the first panel outer frame 1A of the above-mentioned general structural parts, the upper ...

specific Embodiment approach 3

[0084] Such as Figure 12 As shown, a 16A socket glass panel 11 with a socket middle hole is set in the front of the first panel outer frame 1A by pressing and bonding, and a nut 23 is installed in the upper lining nut mounting hole 2-4 of the upper lining 2, Install the module lower case 5 behind the metal liner 3, and the module lower case 5 is tightened with the nut installed in the upper liner by the screw 24, and at the same time, the module lower case 5, socket lower cover 17, metal liner 3 and upper liner The board 2 is fixed, and the socket intelligent module circuit board 18 and the copper terminal 4 are installed in the module lower shell 5, and a copper sheet insertion interface is left on the socket intelligent module circuit board 18; the concealed socket L contact piece 16, and the concealed socket E are grounded The metal sheet 15 and the concealed socket N contact piece 14 are first fixed on the socket lower cover 17, and then inserted into the copper sheet soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com