A device for automatically removing the upper cover of a tuning fork crystal

A tuning fork crystal and automatic technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of inconvenient operation, low production efficiency, and fatigue after long-term work, and achieve the effect of improving work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

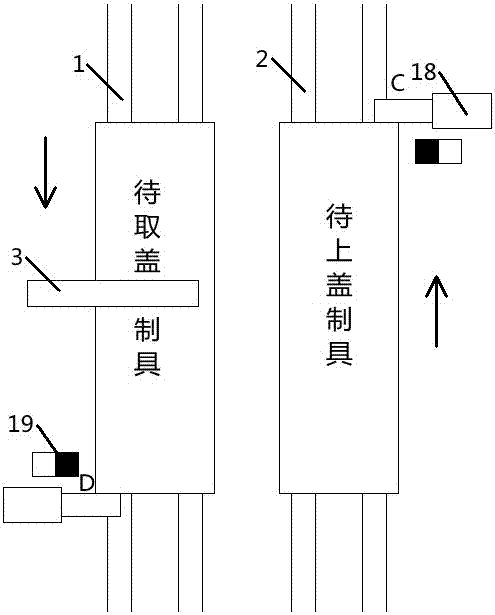

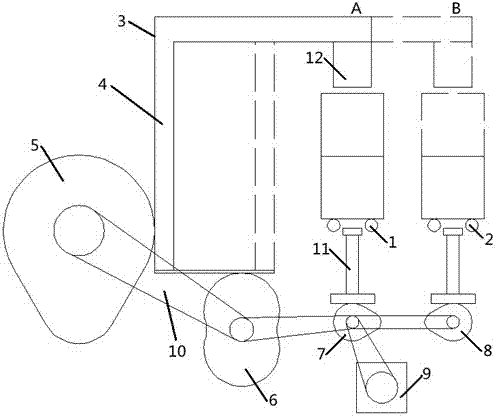

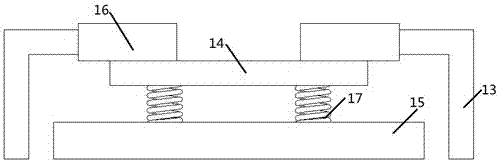

[0015] see Figure 1-Figure 3 , a tuning fork crystal automatic capping device, comprising a capping track 1 and a capping track 2 running in reverse, the outer side of the capping track 1 is equipped with a capping mechanism 3, said Get loam cake mechanism 3 and comprise frame 4, frame X-axis cam 5, frame Z-axis cam 6, get cover cam 7, loam cake cam 8 and driving motor 9, described frame X-axis cam 5, frame Z The shaft cam 6, the cover cam 7, the upper cover cam 8 and the driving motor 9 are connected to each other by a synchronous belt 10, and the frame X-axis cam 5 and the frame Z-axis cam 6 are respectively positioned at the side and the Bottom, where the X-axis cam 5 of the frame is responsible for the lateral displacement of the frame 4, the Z-axis cam 6 of the frame is responsible for the vertical displacement of the frame 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com