Automatic feeding mechanism of full-automatic bagged cargo stacking machine

An automatic feeding and palletizing technology, which is applied in the stacking of objects, de-stacking, transportation and packaging of objects, etc., can solve the problems of unsmooth conveying of bagged goods and low shaping precision, and achieve high shaping precision, Reasonable structural design and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

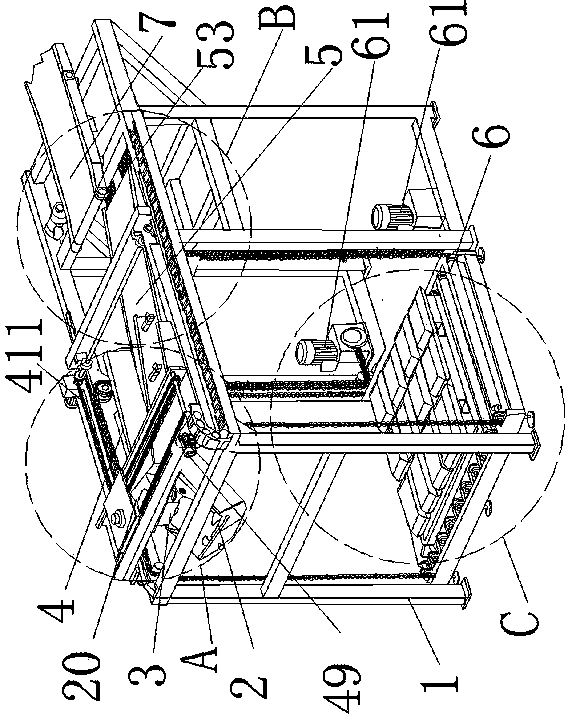

[0060] Example 1. Such as Figure 1-13 As shown, an automatic feeding mechanism for a fully automatic bagged goods palletizer is characterized in that it includes a frame body 1 and a movable feeding device 5 arranged on the frame body 1, and a horizontally movable cargo extraction device 20, The cargo picking device 20 is arranged on the top of the frame body 1 .

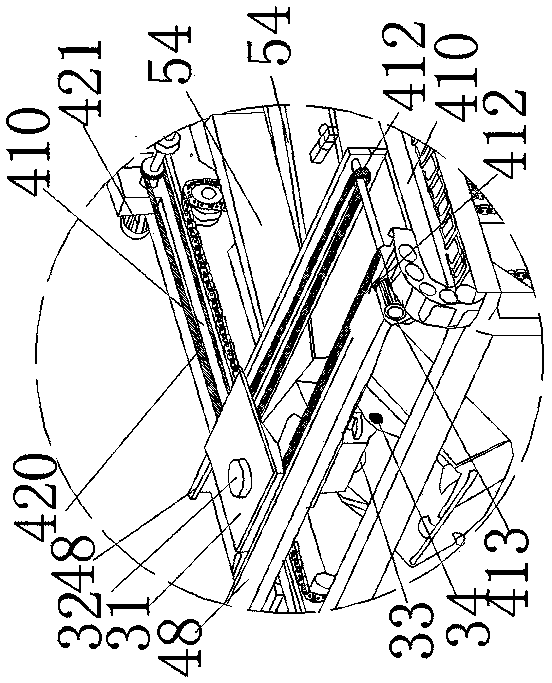

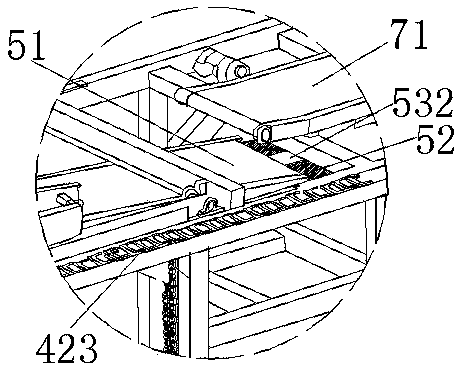

[0061] The movable feeding device 5 includes a movable feeding conveyor belt support platform 52 arranged on one side of the cargo extraction device 20 on the frame body 1; An active feed conveyor belt 51 is provided; one end of the movable feed conveyor belt 51 is hinged with the cargo extraction device 20, and the other end of the movable feed conveyor belt 51 is placed on the movable feed conveyor belt support platform 52 and is installed on the The rectilinear sliding device 53 that can linearly reciprocate on the movable feeding conveyor belt support platform 52 is hinged, and the bagged goods 9 are transpor...

Embodiment 2

[0079] Example 2. Such as Figure 15 As shown, the difference between this embodiment and Embodiment 1 lies in that: the goods extraction device 20 is arranged on the right side of the top of the frame body 1; The top surface is a flat movable feeding conveyor belt support platform 52; a movable feeding conveyor belt 51 is provided between the movable feeding conveyor belt supporting platform 52 and the cargo extraction device 20 on the frame body 1; the right end of the movable feeding conveyor belt 51 It is hinged with the cargo extraction device 20, and the left end of the movable feeding conveyor belt 51 is hinged with the sliding block 531; the right end of the movable feeding conveyor belt 51 is provided with a pair of cargo tightening baffles 54; the cargo supply device 7 is arranged on the frame body 1 to move Above the right end of the feed conveyor belt 51 . The longitudinal motion driving device 49 includes a longitudinally retractable device 414 arranged between ...

Embodiment 3

[0081] Example 3. Such as Figure 20 As shown, the difference between this embodiment and Embodiment 2 is that the pallet lifting device 6 includes four pallet lifting hydraulic cylinders 612 and a pallet frame 64, and the pallet lifting hydraulic cylinders 612 are installed under the pallet frame 64; There are a number of idler rollers 65 whose top surfaces are parallel to each other on the same plane, each idler roller 65 is provided with a sprocket 66, and the sprockets 66 of adjacent idler rollers 65 are connected by a transmission chain 67, and at least one idler roller 65 A transmission wheel 68 is arranged on it, and the transmission wheel 68 is connected with a power output wheel 610 of a roller rotation driving motor 69 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com