Splicer

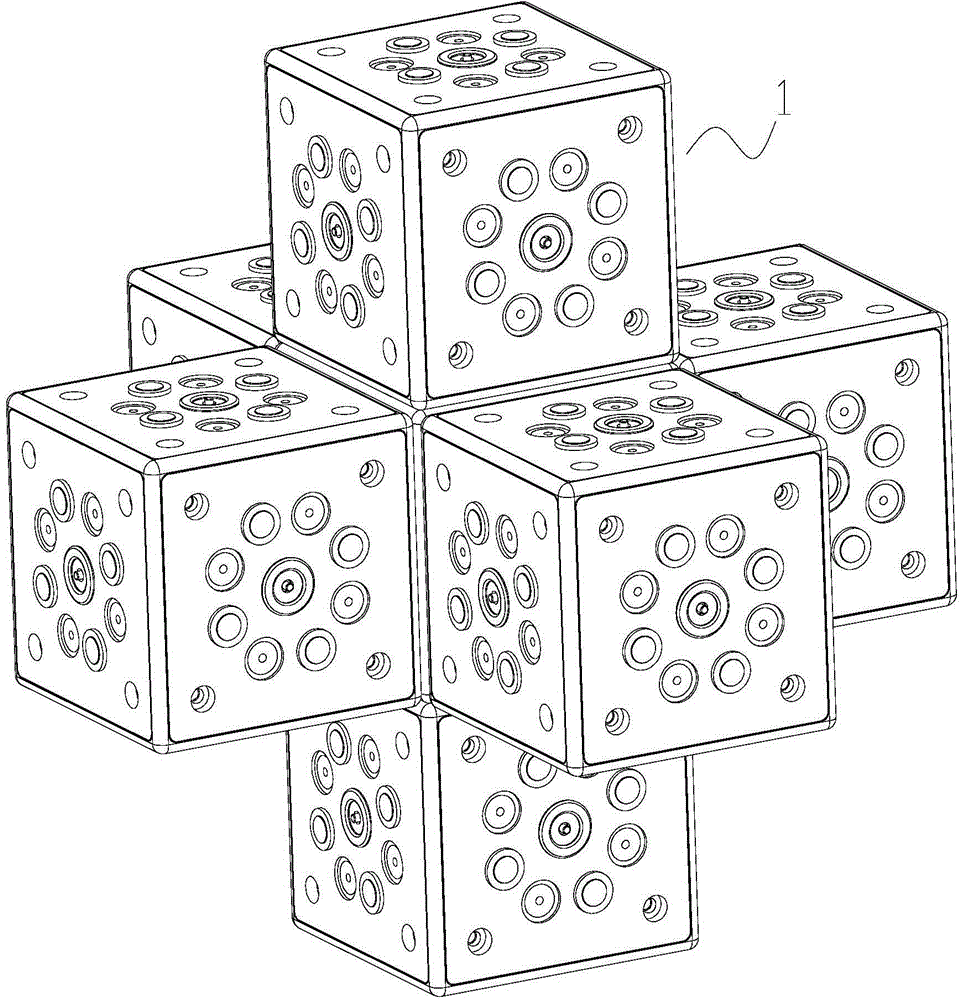

A technology of splicing parts and electrical connectors, applied in entertainment, toys, etc., can solve the problems of inability to splice graphics, practical and interesting bottlenecks of electronic building blocks, and inability to create splicing methods, so as to achieve rich and diverse splicing methods Sexual, easy splicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

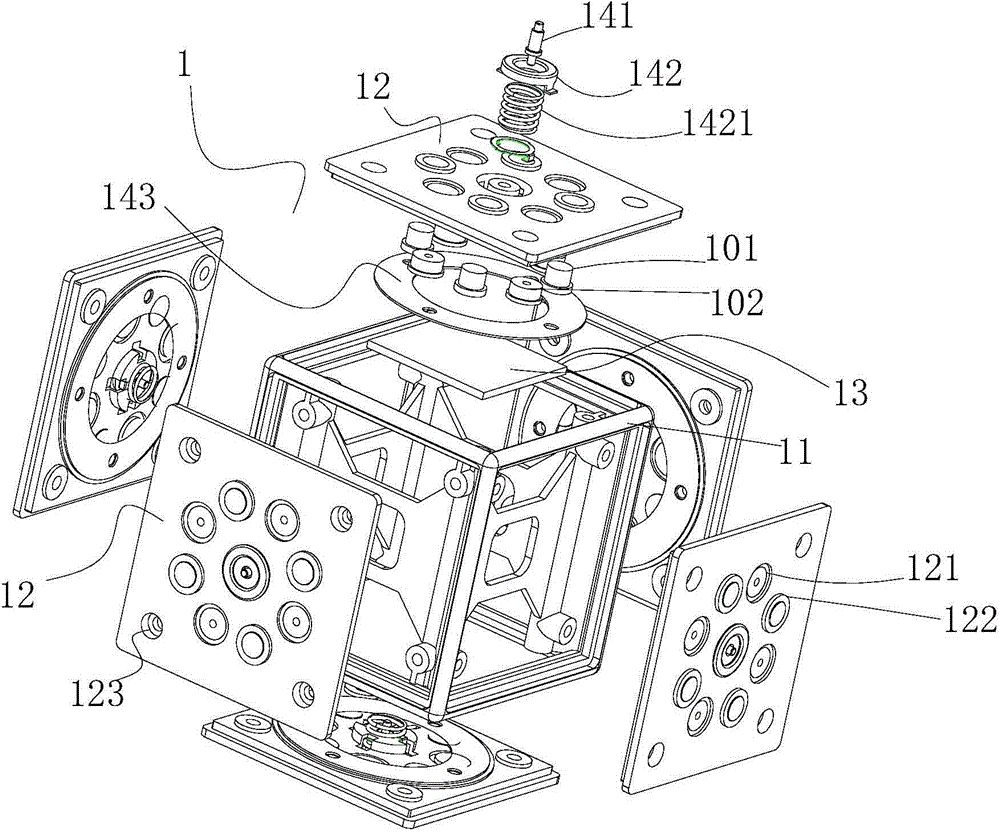

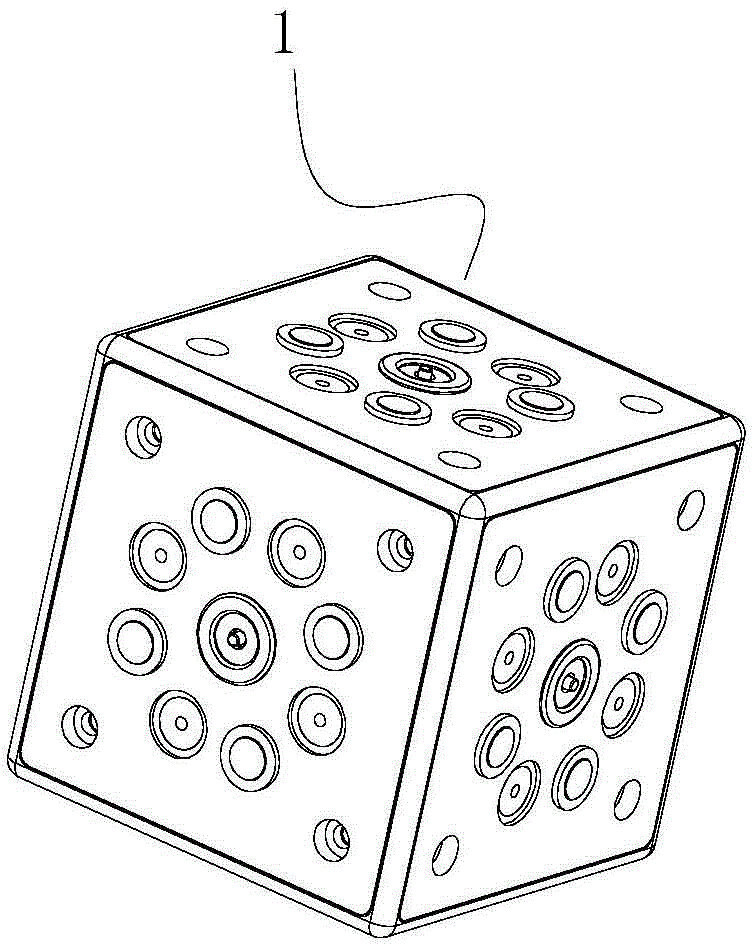

[0042] Embodiment one, such as figure 1 , 2 , 3 shown. In this embodiment, the splicing piece includes several independent identical cube blocks 1, and the magnetic components on each surface of the block 1 are composed of four magnetic blocks 101 and four magnetic metals 102 arranged at intervals in sequence. , one of the preferred layout methods see Figure 10 Schematic: each magnetic block 101 and magnetic metal 102 are not placed on the center line of the square surface 12 of the block (this ensures that the mirror image principle can be used correctly to realize the mutual interaction between the magnetic block and the magnetic metal on different block surfaces. Matching), each magnetic block 101 and the center point where the magnetic metal 102 is placed are sequentially connected to an octagon concentric with the square surface 12 of the block (including but not limited to a regular octagon, other octagons that meet the conditions It can also be realized), the octago...

Embodiment 2

[0048] Embodiment two, such as Figure 4 , 5 , 6 shown. In this embodiment, the splicing piece includes several independent identical cube blocks 2, and the magnetic attraction assembly on each face of the block 2 includes a fool-proof structure and a radial filling that is concentrically arranged with the square surface of the block. Magnetic ring magnet 20, after the ring magnet 20 is radially magnetized, the magnetism on its surface is S-N relationship. Installed on the square surface of the block 2; when the two faces of the two blocks are close together, as if the side is an N-S pole, the ring magnet 20 is mutually repulsive, and at this time the ring magnet 20 will be on the plastic cover 22 Rotate in the cavity 24, self-adjust to the position where the magnetic poles attract each other.

[0049] The fool-proof structure is to prevent the phenomenon that the four sides of the blocks do not overlap during the stacking process. The optimal design of the fool-proof struc...

Embodiment 3

[0054] Embodiment three, such as Figure 7 , 8 , as shown in 9. In this embodiment, the splicing piece includes several independently identical cube blocks 3, and the magnetic assembly on each face of the block 3 is composed of four magnetic blocks 30 and a magnetic metal ring sheet 343; The center point of block 30 is evenly distributed on a circle with the center point of the block square surface 32 as the center of the circle, as Figure 11 As shown, none of the magnetic blocks 30 can be located on the centerline and diagonal of the square surface 32 of the block (this ensures that the mirror image principle can be used correctly to prevent the correspondence between the magnetic block and the magnetic block), each block on each block The polarity and setting positions of the four magnetic blocks facing the surface are the same, for example, all magnetic blocks 30 are N poles facing outside the surface of the block, and S poles are facing in the block; or, all magnetic bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com