Full-automatic heat-conduction paste coating machine

A technology of thermal conductive paste and coating machine, which is applied to coatings, devices that apply liquid to the surface, etc., can solve the problems of consuming more thermal conductive paste, time-consuming, and low coating efficiency, so as to reduce leakage and cleaning cycles. , The effect of saving feeding time and high coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

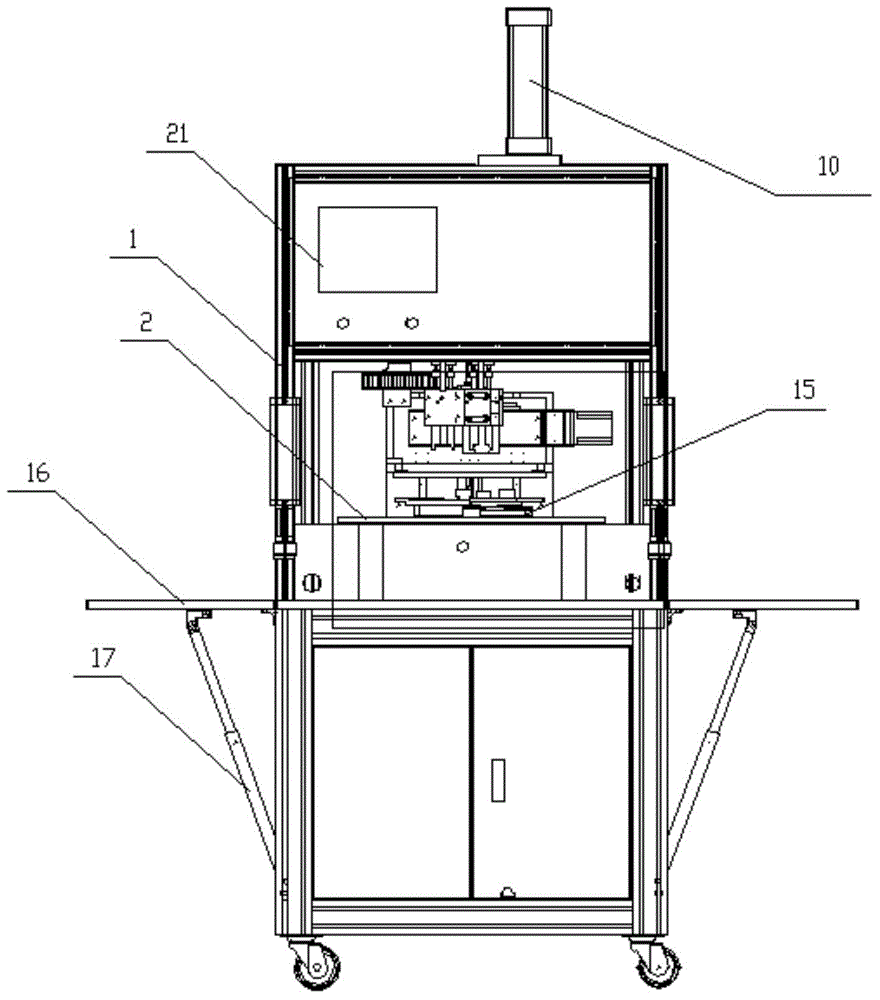

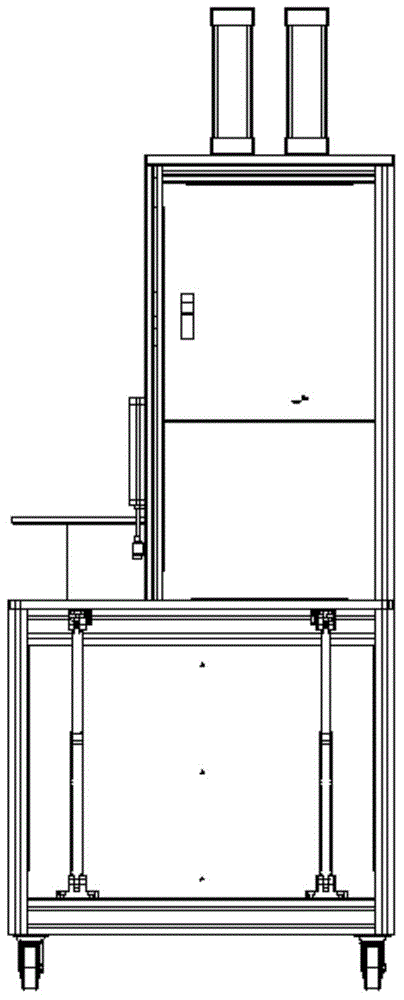

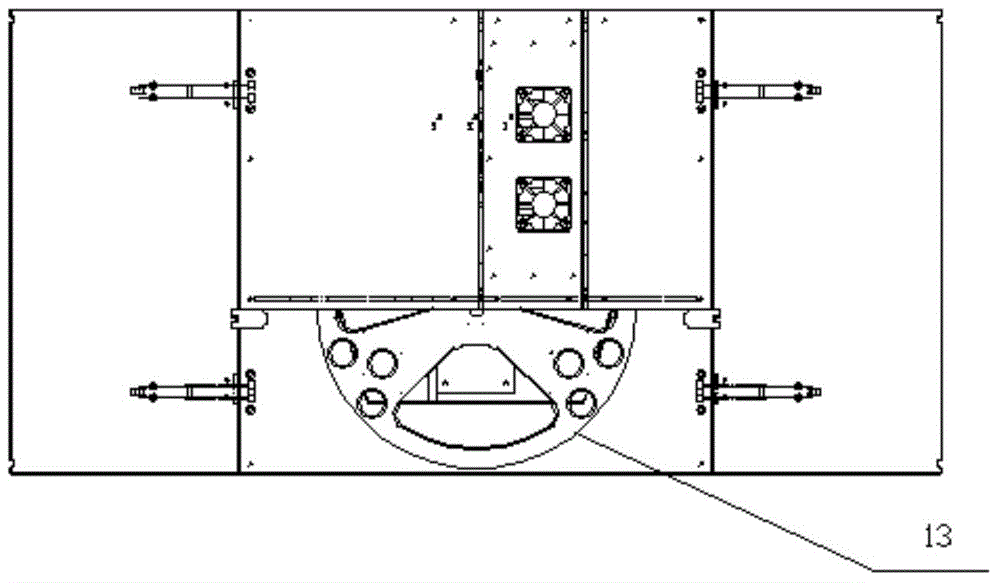

[0023] Embodiment: A fully automatic heat conduction paste coating machine, including a frame 1, a workbench 2, a heat conduction paste coating mechanism, a heat conduction paste feeding mechanism and a controller, wherein:

[0024] The workbench 2 is fixed on the frame 1, and the workbench 2 is provided with a positioning device for fixing the product to be coated;

[0025] The thermal paste coating mechanism is located above the workbench 2, and the thermal paste coating mechanism includes a fixed frame 3, a coating mechanism driving device 4, a screen frame positioning frame, a coating head positioning frame 5, a coating head 6, and a coating head longitudinal drive Device 7 and coating head horizontal driving device 8, described fixed frame 3 vertically can be slidably positioned on the frame 1, and the screen frame positioning frame can be fixedly positioned on the fixed frame 3, and the screen frame positioning frame is provided with a screen frame 9, The window area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com