Method of removing hardened ink, paint or lacquer with adhesive tape

A coating and thermal hardening technology, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, chemical paint/ink removers, etc., can solve problems such as difficulty in removing ink layers, achieve optimal adhesion, optimize precision, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

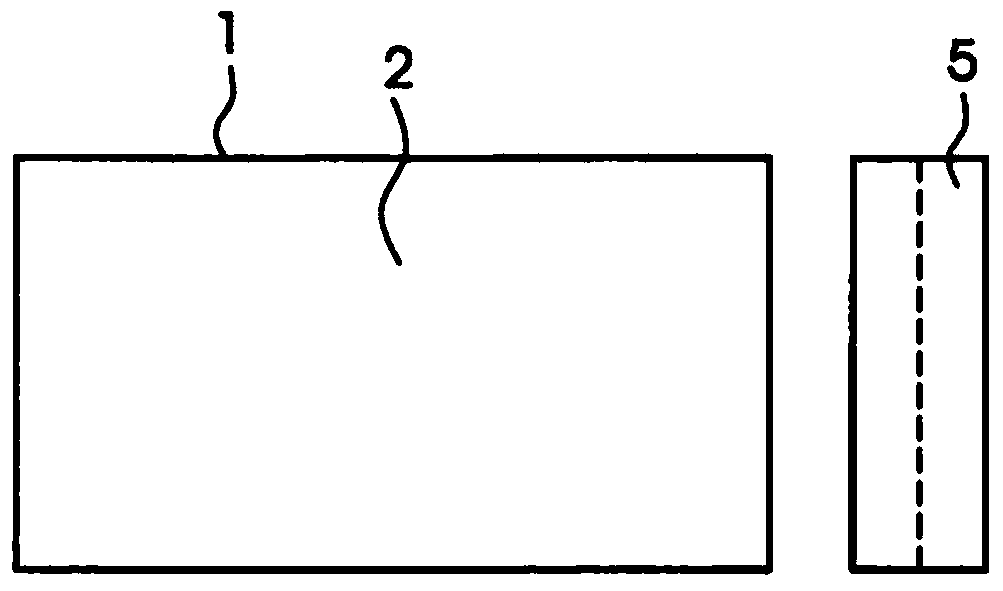

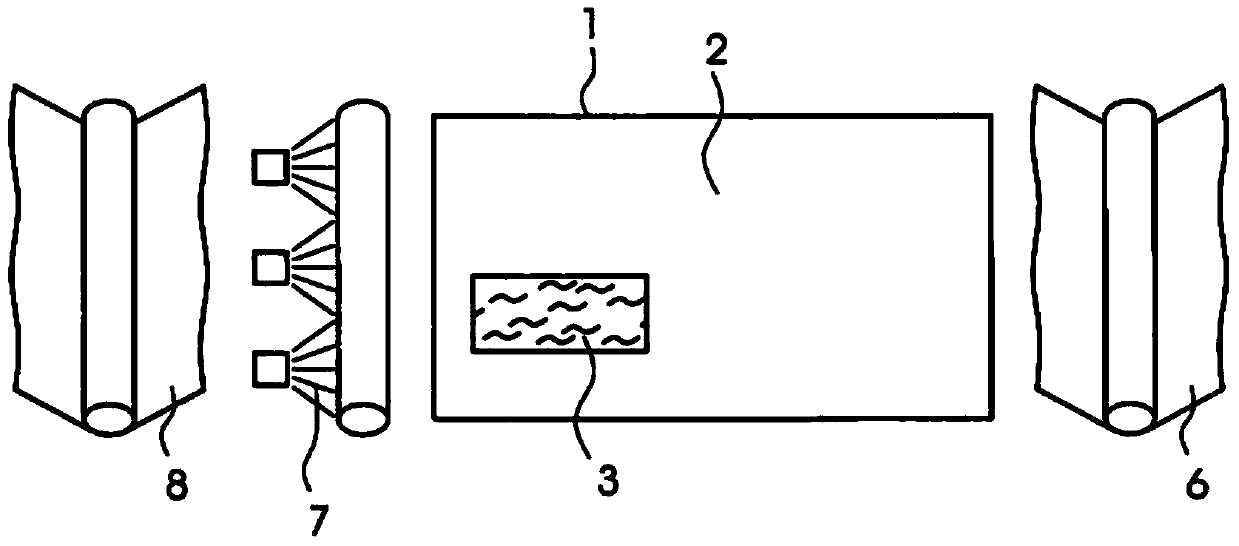

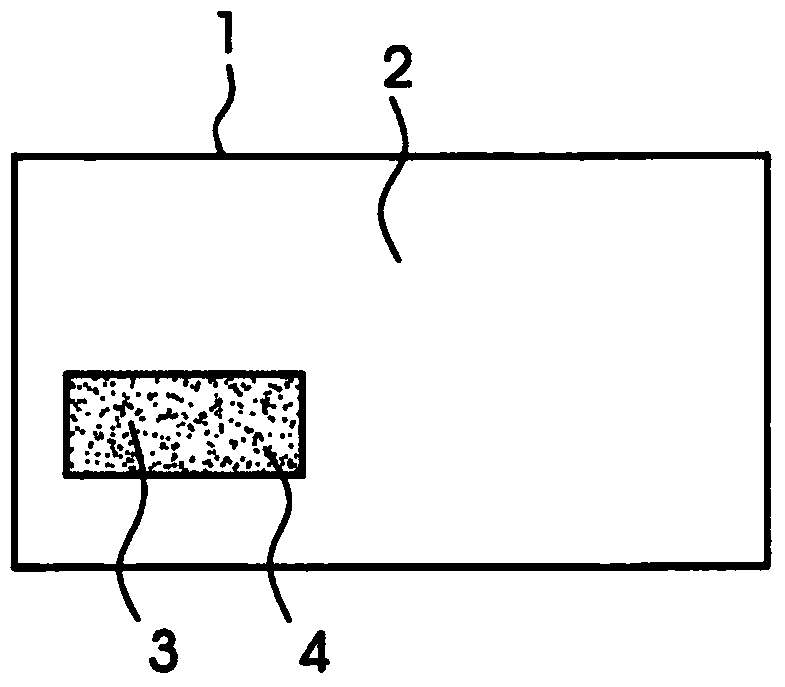

[0024] figure 1 A surface 1 is shown, which is covered with a layer 2 of UV-cured ink. A solvent-free cleaning agent 3 is applied to the part of the surface 1 by the spray head 5, which reduces the adhesion of the UV-cured ink layer 2 on the surface 1, which here does not dissolve. figure 2 A surface 1 to which a cleaning agent 3 is applied is shown. After about 3 minutes of action, the excess cleaning agent 3 is removed with a liquid-absorbent cloth 6 . The parts of the surface 1 treated with the cleaning agent 3 are now rinsed with water 7 and dried, for example, with a cloth 8 or a blower. After drying, such as image 3 As can be seen in , the adhesive film 4 is applied to the part of the surface 1 treated with the cleaning agent 3 . The adhesive film 4 is removed again after it has been applied to the surface 1 . In this case, the ink 2 treated with the cleaning agent 3 adheres to the adhesive film 4 and is removed together with the adhesive film 4 from the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com