Heightened deep-hole gear shaper

A technology of gear shaping machine and deep hole, which is applied in the direction of gear cutting machine, gear teeth, mechanical equipment, etc., and can solve the problem that deep hole internal gear cannot be processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

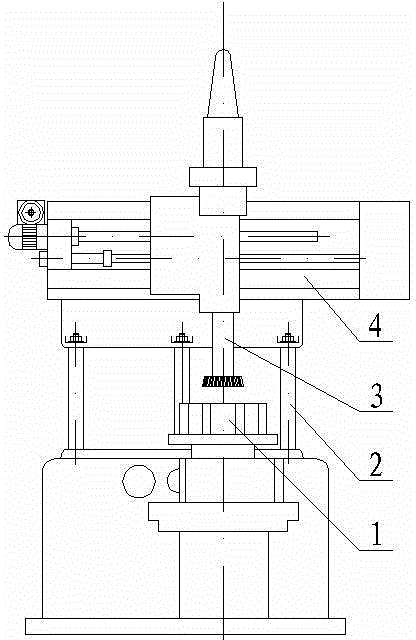

[0011] as attached figure 1 As shown, the present invention includes a rotary table 1 on a common gear shaping machine, a guide rail frame 4, a tool spindle 3 fitted on the rail frame 4, and a heightening column 2 is arranged between the rotary table 1 and the rail frame 4; The length of 3 is equal to the length of the original tool spindle of the ordinary gear shaping machine plus the length of the heightening column 2; there are six heightening columns 2, and the two ends of which are provided with connecting threads, and pass through the original screw holes on the rotary table 1 and the guide rail frame 4 respectively And fasten the two with nuts. In the present invention, a heightening column 2 is provided between the rotary table 1 and the guide rail frame 4 of the ordinary gear shaping machine, which increases the space height between the rotary table 1 and the guide rail frame 4, and increases the length of the tool spindle 3 to make The gear shaping tool can extend i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com