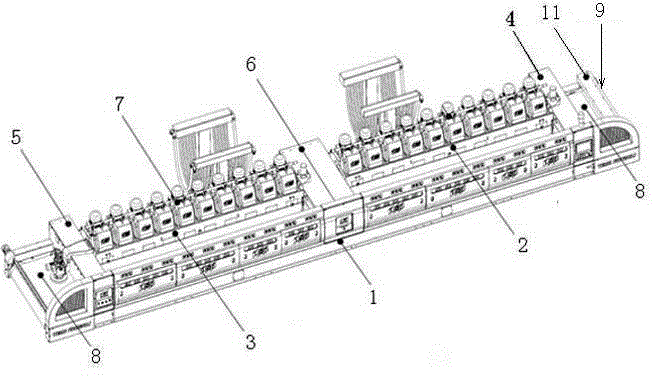

Smart full-automatic stone slab polishing unit

A polishing machine, fully automatic technology, applied in surface polishing machine tools, grinding/polishing equipment, automatic grinding control devices, etc., can solve problems such as low level of numerical control intelligent technology, avoid hidden dangers, improve speed and quality , use full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

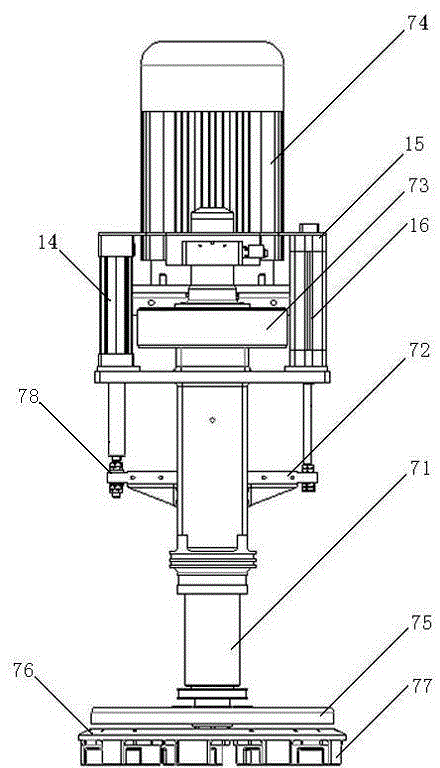

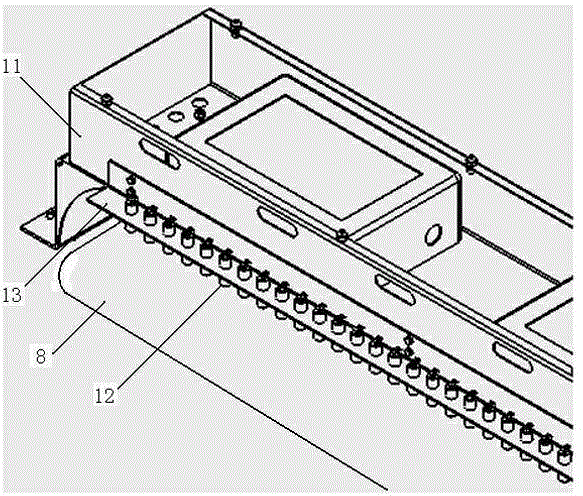

[0017] Embodiment: The industrial control computer controls the lifting of the polishing machine 7 and the front beam 2 and the rear beam according to the input stone slab width, height, and surface parameters to be ground collected by the ultrasonic sensor 12, and the thickness parameters of the polishing head 77 collected by the magnetic grid detector 16 3’s moving parameters, through the parameter input on the touch screen, the independent lifting and forward and backward moving parameters of each polishing machine 7 can be artificially modified, and the independent moving parameters of the front beam 2 and rear beam 3 and the dwell time at the turning point can also be artificially modified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com