Material gathering device

A material collection device and material collector technology, which is applied in the direction of drying gas arrangement, dryer, lighting and heating equipment, etc., can solve the problems of corrosion and wear of the material receiving device, and the state of material transportation cannot be observed, so as to achieve low cost, achieve observable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will describe in detail in conjunction with specific embodiments of the present invention. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

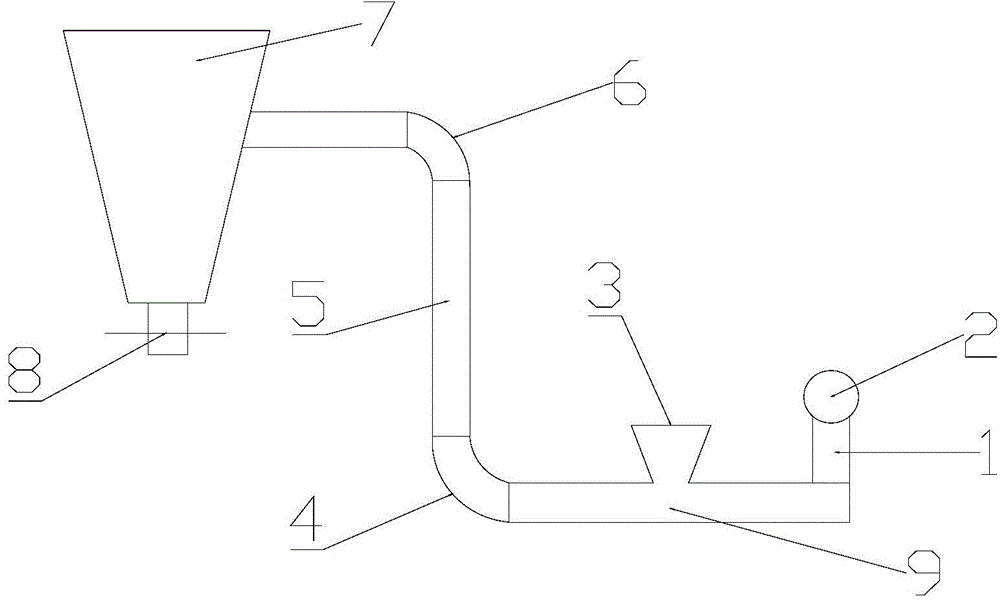

[0024] figure 1 It is a structural schematic diagram of a receiving device provided by the present invention, which includes: a receiving hopper 3, a blower 2, a heater 1, a connecting pipe 9, a conveying pipeline and a material collector 7, wherein the outlet of the receiving hopper 3 The feed port is communicated with the side of the connecting pipe 9, one end of the connecting pipe 9 is communicated with the air outlet of the blower 2, the other end is communicated with one end of the conveying pipeline, and the other end of the conveying pipeline is communicated with the collector. The feeder 7, the heater 1 is installed at the air outlet of the blower 2.

[0025] The working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com