Integrated equipment for mulching, cutting and mark pressing

A technology of lamination and creasing, applied in printing, rotary printing presses, printing presses, etc., can solve the problems of low operation efficiency, multiple labor costs, increased investment in fixed assets, etc., and achieve cost-saving, good economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

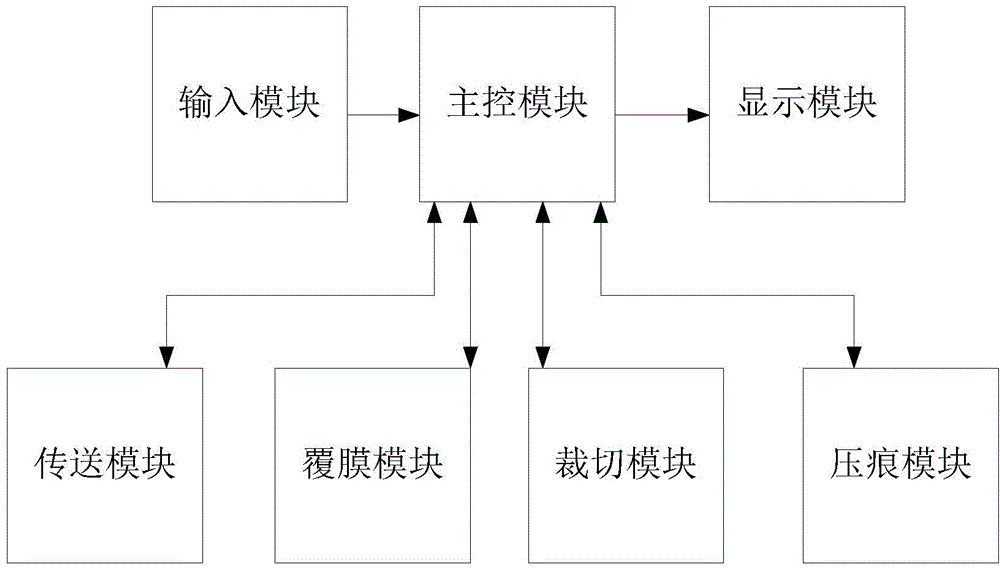

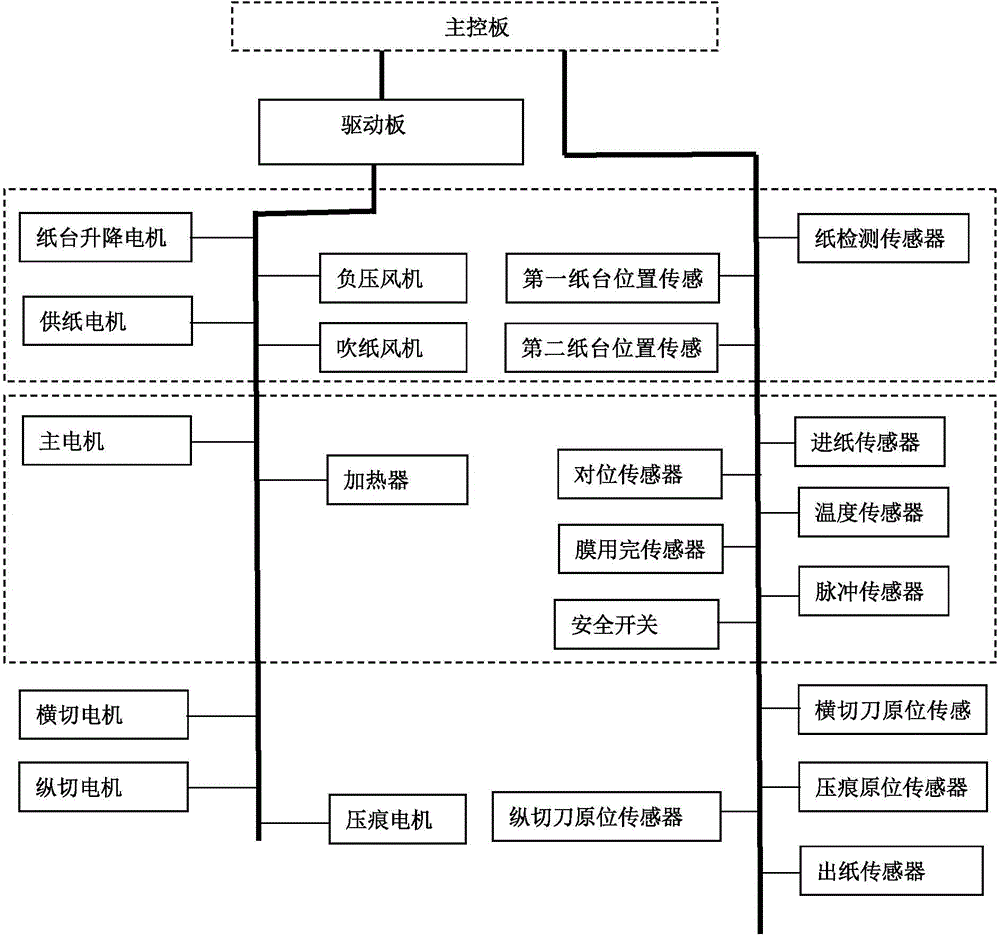

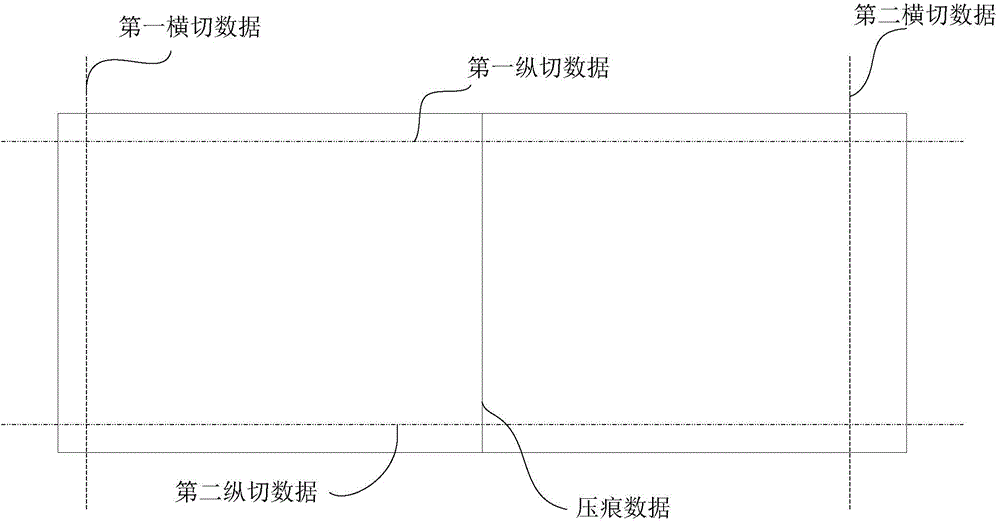

[0022] like figure 1 and figure 2 As shown, a kind of laminating, cutting and creasing integrated equipment is characterized in that it includes: a main control module, which is used to control and coordinate the work of the laminating module, cutting module and creasing module; the transmission module includes Multiple groups of rubber roller groups, the transmission module is used to receive the command of the main control module to transmit the paper to the designated position; the lamination module includes a temperature sensor, a heater and a lamination roller, the main control module collects the temperature sensor data, and Control the heater to heat, so that the temperature of the lamination roller is stabilized within the preset lamination temperature value; the cutting module includes a slittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com