Automotive brake pump side wiring harness protection box

A wire harness protection box and wire protection box technology, which is applied to vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of wire harness damage, wire harness crushing, open circuit, etc., to achieve functional optimization and solve the problem of wire crossing Problems, effects of efficient use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

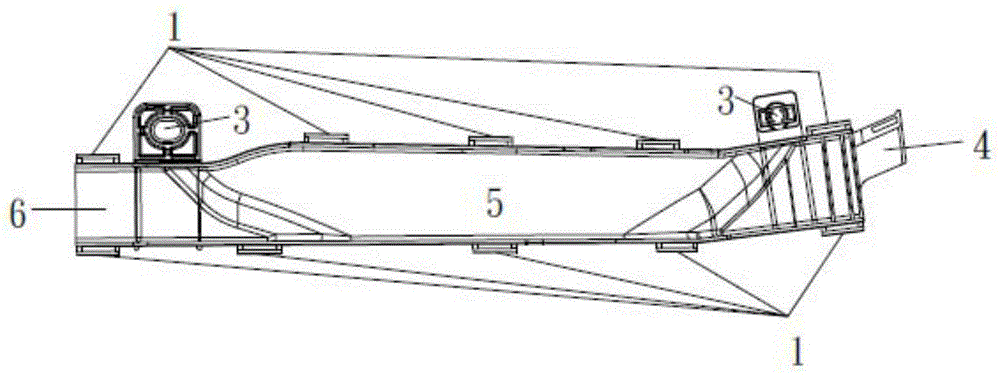

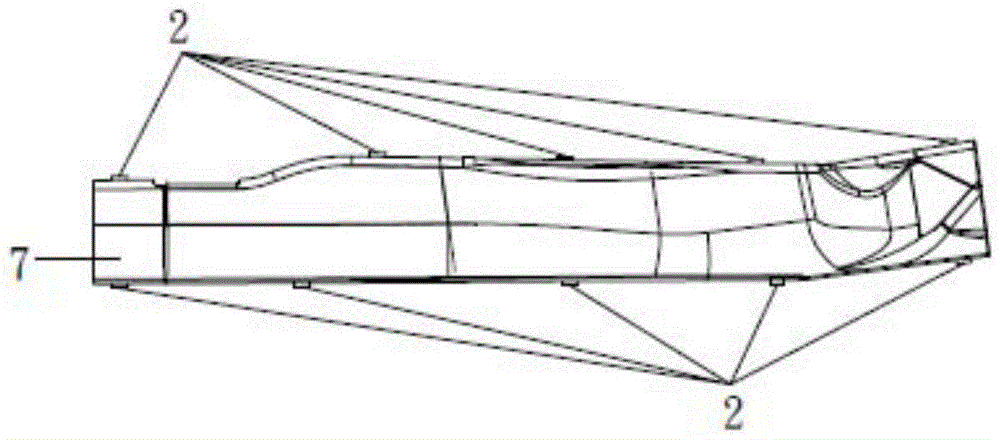

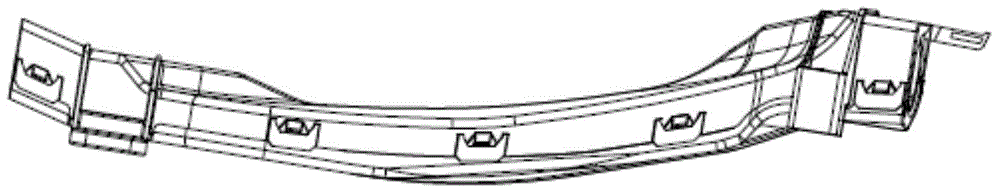

[0018] Such as figure 1 , figure 2 and image 3 As shown, a wire harness box next to the brake pump for a vehicle includes an assembly buckle 1, an assembly buckle 2, a fixing hole 3, a wire binding plate 4, a wire groove 5, a lower cover 6 of the wire protection box and an upper cover of the wire protection box Cover 7, the two sides of the upper cover 7 of the wire protection box and the lower cover 6 of the wire protection box are respectively equipped with an assembly buckle 2 and an assembly buckle 1, and the assembly is realized through the assembly buckle 1 / 2; the end of the lower cover 6 of the wire protection box is provided with The wire binding plate 4, the wire binding plate 4 is used to fix the wire harness on the wire protection box to prevent the wire harness from moving, and at the same time, a wire groove 5 is provided for wiring the wire harness; the upper cover 7 of the wire protection box is matched with the lower cover 6 of the wire protection box Final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com