A dual-pulse sewage treatment system

A sewage treatment system, double-pulse technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve problems such as poor operation effect and energy waste, Achieve high oxygen utilization efficiency, reduce operating costs, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described with reference to the drawings and specific embodiments.

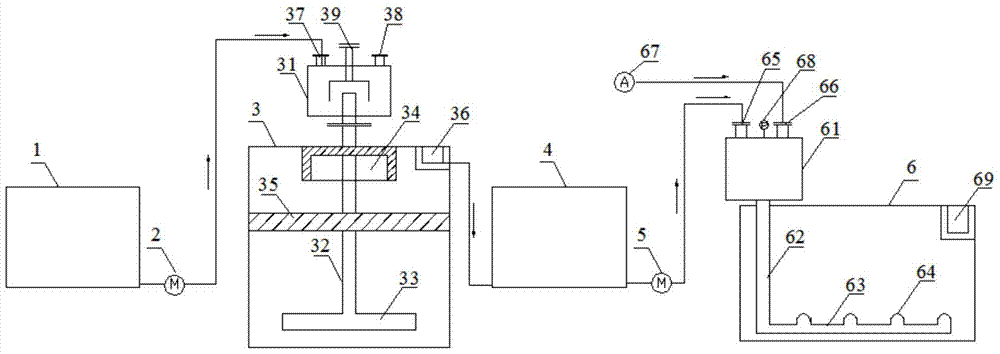

[0017] Such as figure 1 As shown, a dual-pulse sewage treatment system includes: 1# storage tank 1, 1# lift pump 2, anaerobic pulse reaction tank 3, 2# storage tank 4, 2# lift pump 5, aerobic pulse reaction tank 6 The 1# storage tank 1 is connected to the anaerobic pulse reaction tank 3 by the 1# lift pump 2, the anaerobic pulse reaction tank 3 and the 2# storage tank 4 are connected, and the 2# storage tank 4 is connected by 2# Lift pump 5 is connected to aerobic pulse reaction tank 6.

[0018] The anaerobic pulse reaction tank includes: anaerobic tank, pulse generator 31, generator connecting pipe 32, water distribution pipe 33, biogas chamber 34, three-phase separator 35, water outlet weir 36; A pulse generator 31 is installed on the top. The upper end of the pulse generator 31 is provided with an inlet pipe 37, an inlet pipe 38 and an outlet pipe 39 respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com