A kind of ecological concrete for slope greening and preparation method thereof

An ecological concrete and slope technology, applied in the field of slope greening, can solve the problems of being unsuitable for plant survival, low adhesion of foreign soil, prone to landslides, etc., to promote plant rooting and growth, less cement consumption, and improved strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation method for the ecological concrete of slope greening, comprises the following steps:

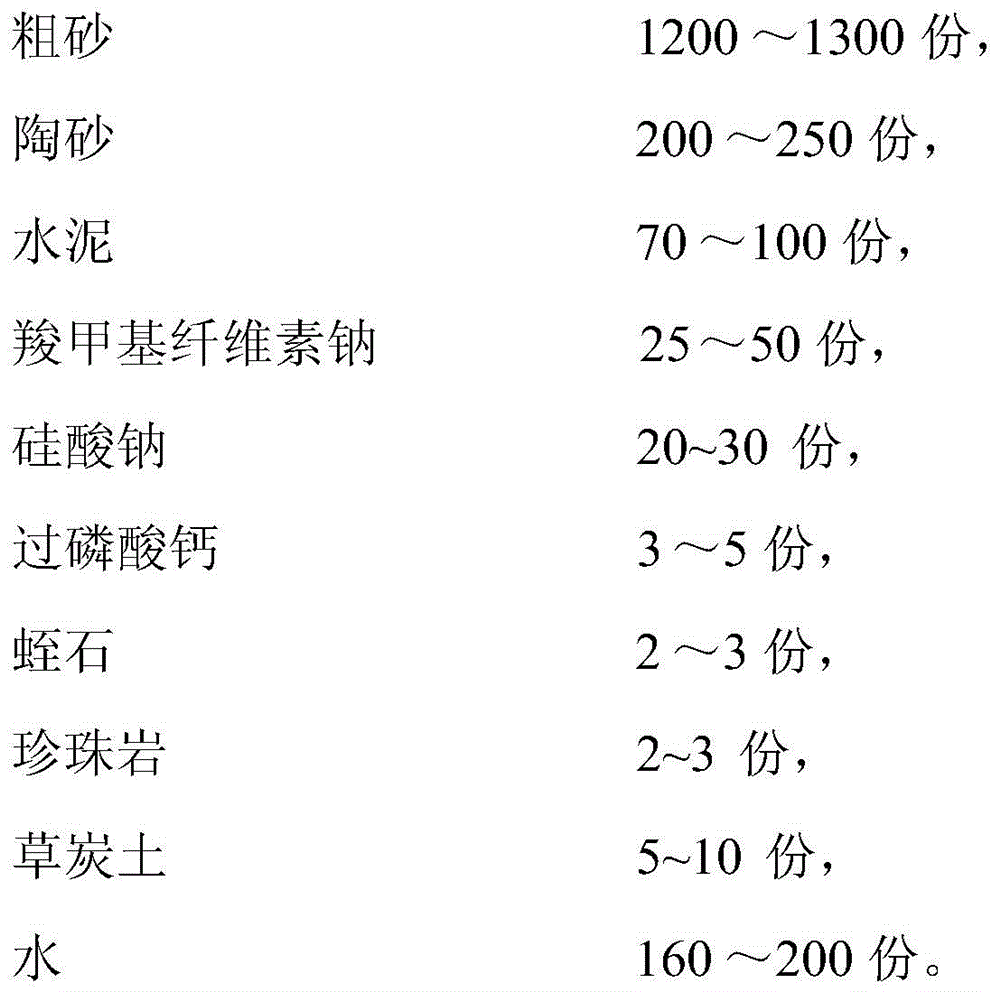

[0044] A. Prepare the following raw materials in parts by weight on a dry basis:

[0045]

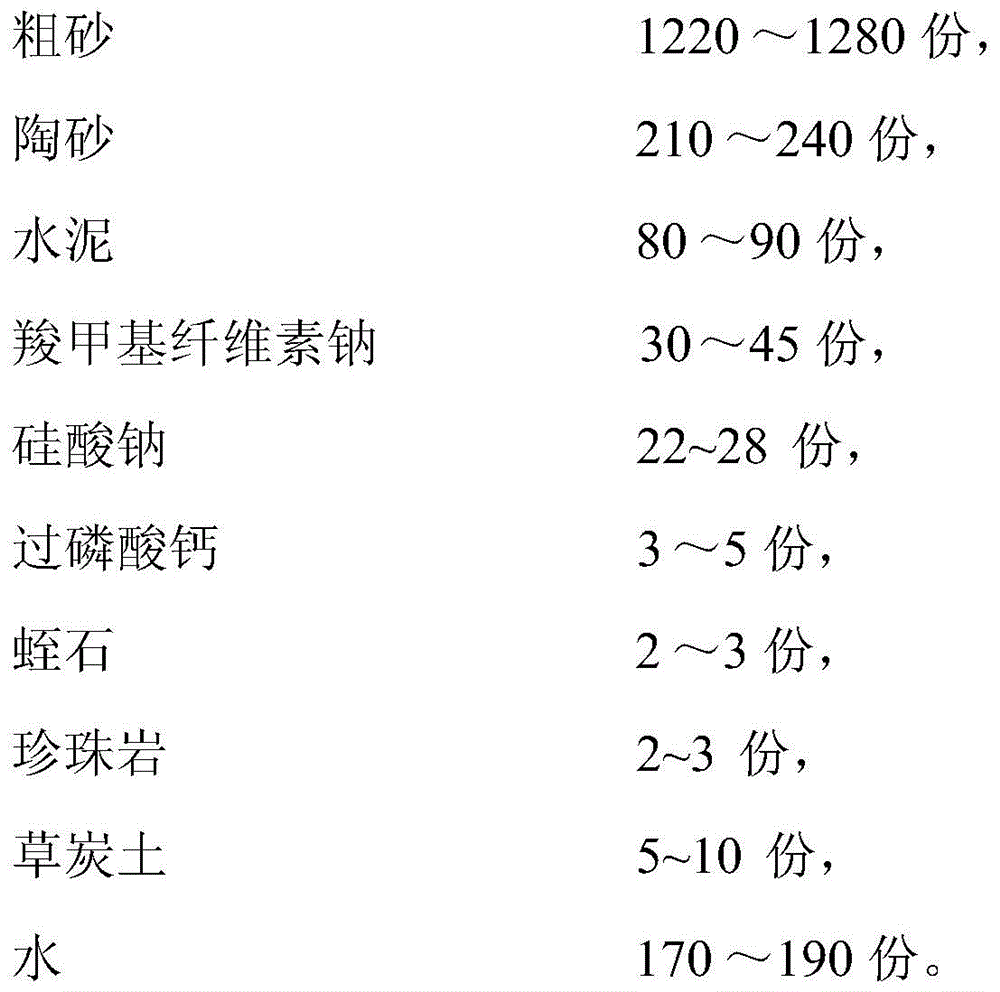

[0046] Preferably, the following raw materials are prepared in parts by weight on a dry basis:

[0047]

[0048]

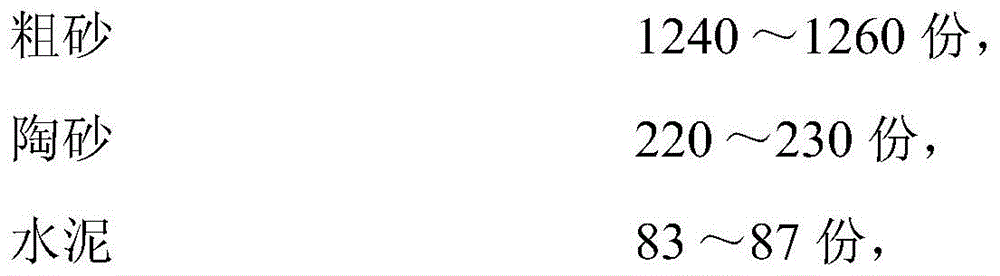

[0049] Further preferably, the following raw materials are prepared in parts by weight on a dry basis:

[0050]

[0051] Still further preferably, in parts by weight on a dry basis, the following components are included:

[0052]

[0053]

[0054] B. Put coarse sand, pottery sand, cement, vermiculite and perlite into the first mixer and stir for 2 to 3 minutes; put sodium carboxymethyl cellulose, sodium silicate, superphosphate and water into the second mixer, Stir for 2 to 3 minutes, and the preferred stirring time is 3 minutes.

[0055] C. Put the materials in the second mixer into the first mixer, and...

Embodiment 1

[0059] Embodiment 1 provides a kind of ecological concrete that is used for slope greening, in terms of parts by weight on a dry basis, including the following components: 1200 parts of coarse sand, 200 parts of pottery sand, 70 parts of cement, and 25 parts of sodium carboxymethyl cellulose , 20 parts of sodium silicate, 3 parts of superphosphate, 2 parts of vermiculite, 2 parts of perlite, 5 parts of peat soil, and 160 parts of water.

[0060] Preparation method: Prepare the following raw materials in parts by weight on a dry basis: 1200 parts of coarse sand, 200 parts of pottery sand, 70 parts of cement, 25 parts of sodium carboxymethyl cellulose, 20 parts of sodium silicate, 3 parts of superphosphate, 2 parts of vermiculite, 2 parts of perlite, 5 parts of peat soil, 160 parts of water; put coarse sand, pottery sand, cement, vermiculite and perlite into the first mixer and stir for 2 minutes; mix sodium carboxymethyl cellulose, silicon Put sodium phosphate, calcium superpho...

Embodiment 2

[0062] Embodiment 2 provides a kind of ecological concrete that is used for slope greening, in terms of parts by weight on a dry basis, including the following components: 1300 parts of coarse sand, 250 parts of pottery sand, 100 parts of cement, and 50 parts of sodium carboxymethyl cellulose , 30 parts of sodium silicate, 5 parts of superphosphate, 3 parts of vermiculite, 3 parts of perlite, 10 parts of peat soil, and 200 parts of water.

[0063] Preparation method: in parts by weight on a dry basis, prepare the following raw materials: 1300 parts of coarse sand, 250 parts of pottery sand, 100 parts of cement, 50 parts of sodium carboxymethyl cellulose, 30 parts of sodium silicate, 5 parts of superphosphate, 3 parts of vermiculite, 3 parts of perlite, 10 parts of peat soil, 200 parts of water; put coarse sand, pottery sand, cement, vermiculite and perlite into the first mixer and stir for 3 minutes; mix sodium carboxymethyl cellulose, silicon Put sodium phosphate, calcium super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com