High-insulating cable sheath material

A cable sheath, high insulation technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

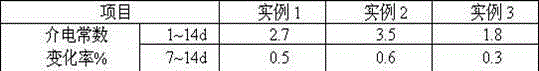

[0025] Examples 1 to 3: A high-insulation cable sheath material, the high-insulation cable sheath material is composed of the following components by weight as shown in Table 1:

[0026] Table 1

[0027]

[0028] The above are parts by weight.

[0029] The above-mentioned silane coupling agent is vinyl tris (β-methoxyethoxy) silane, vinyl trimethoxy silane or γ-glycidoxypropyl trimethoxy silane.

[0030] The above-mentioned silane coupling agent is vinyl tris (β-methoxyethoxy) silane, vinyl trimethoxy silane and γ-glycidoxypropyl trimethoxy silane mixed in a ratio of 10:5:3 parts by weight .

[0031] The lubricant example 1 above is polyethylene wax, the lubricant example 2 is stearic acid, and the lubricant example 3 is a composite of polyethylene wax and stearic acid.

[0032] Example 1 of the above antioxidant is tetra[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, Example 2 is bisphenol A, and Example 3 is tetra[3- (3,5-Di-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com